High-sensitivity vibration sensor

A vibration sensor and high-sensitivity technology, which is applied in the direction of instruments, measuring devices, and electrical devices, can solve the problems of low sensitivity, limited vibration signal response, and small output electrical signal of the sensor, so as to improve sensitivity and increase polarization charge Quantify and expand the effect of transverse stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

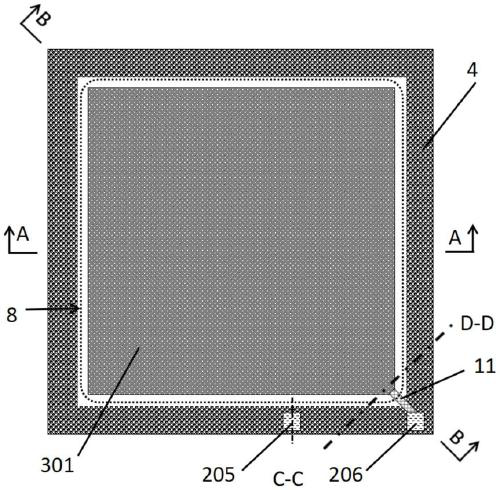

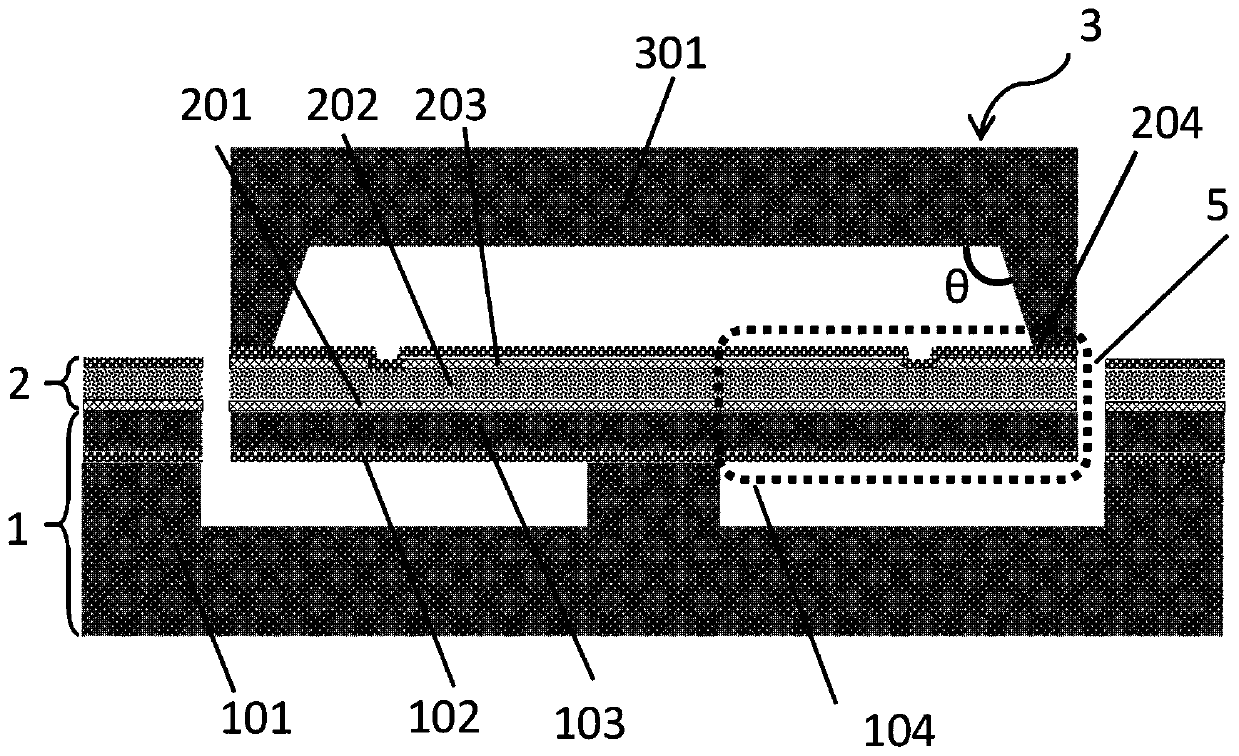

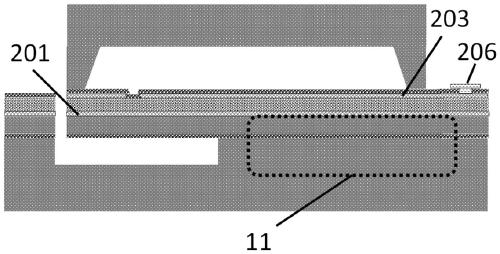

[0024] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0025] The present invention uses a sealing cap with a groove, and the groove edge of the sealing cap is connected with the free end of the piezoelectric cantilever beam, so that the load in the vertical direction generated by the vibration signal is concentrated on the free end of the piezoelectric cantilever beam, which will make the piezoelectric cantilever The greater the bending moment on the beam, the greater the deflection of the piezoelectric cantilever beam. This structure can effectively expand the lateral stress on the piezoelectric film on the piezoelectric cantilever beam and increase the polarization charge generated on the upper and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com