Ventilation method suitable for exhaust gas generation site

A ventilation method and exhaust gas technology, which can be used in separation methods, ventilation systems, space heating and ventilation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

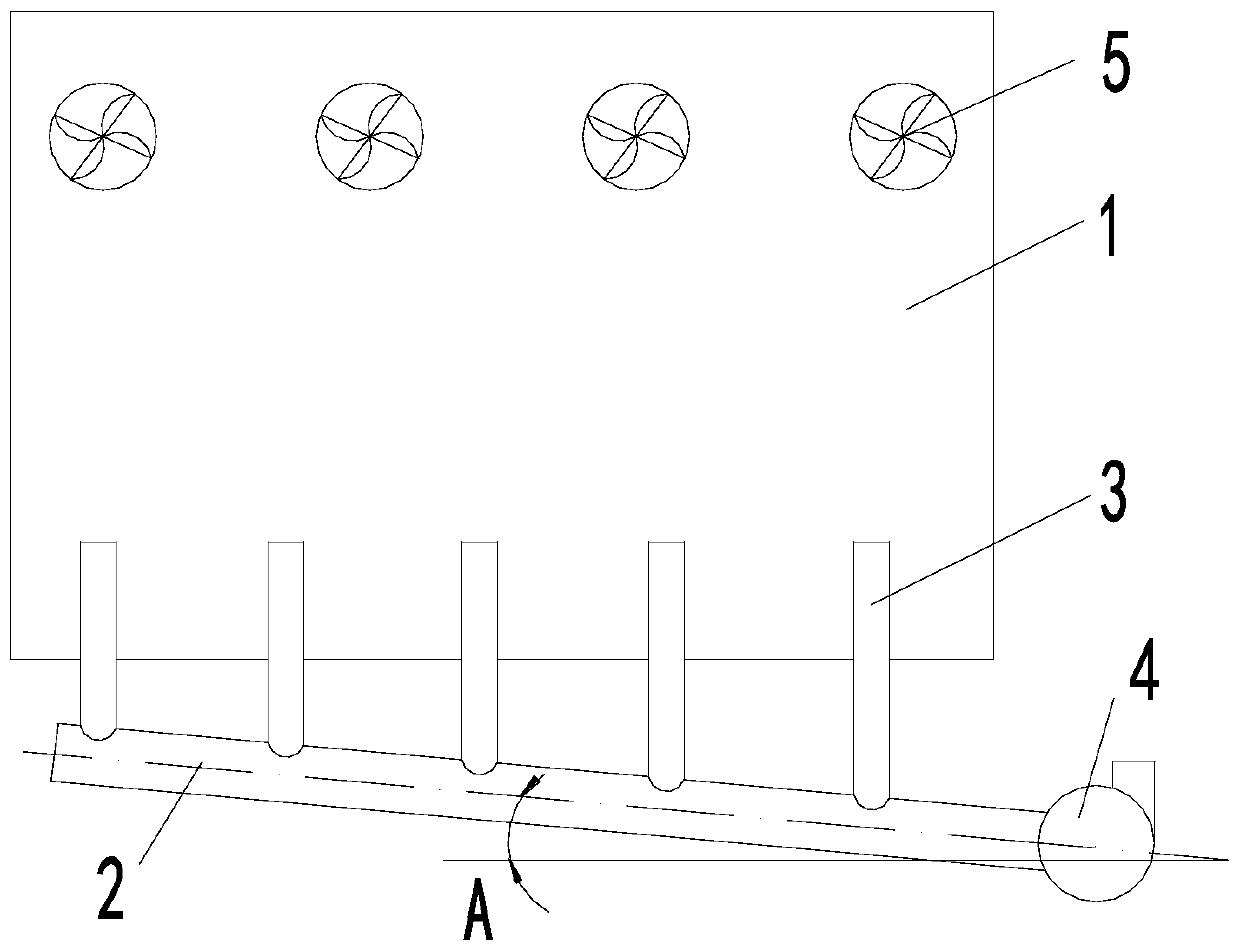

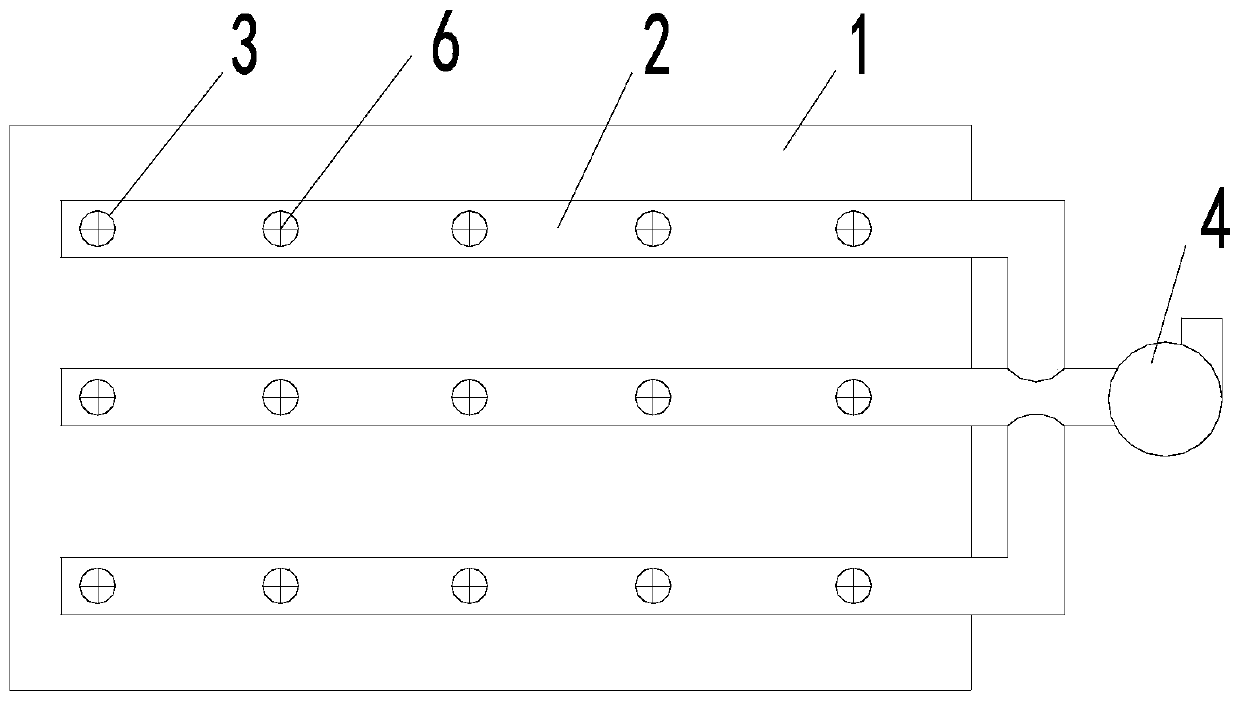

[0018] The present invention is applicable to the ventilation and ventilation of hazardous waste warehouses or distributed waste gas production workshops. An inclined pipeline ventilation array 2 is installed underground in waste gas pollutant production places 1 such as hazardous waste warehouses or distributed waste gas production workshops. The pipelines can be circular. Tubes are formed by connecting multiple tubes. Each pipe on the pipe ventilation array 2 is inclined to one side, the high side is sealed at one end, and the low side is connected to the induced draft fan 4, and the exhaust gas pollutants are discharged from the generation site 1 through the induced draft fan 4 and processed, and the exhaust gas after treatment can be recycled . The inclination angle A of the duct ventilation array 2 is 0-15 degrees.

[0019] There are down-row exhaust pipes 3 distributed in the duct ventilation array 2, and the down-row exhaust pipes 3 extend from the ground of the waste ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com