A multi-stage tubular cyclone oxygenated biological filter sewage treatment system and treatment method

A technology of sewage treatment system and biological filter, applied in the field of water treatment, can solve the problems of small usable area, complicated maintenance and management, large floor space, etc., and achieve the effect of low operating cost, simple process form, and reduced construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The present invention makes full use of the topographic conditions of mountain-type tourist destinations, and provides a multi-stage tubular swirling oxygenated biological filter for sewage treatment based on relevant hydraulic and aerodynamic principles and in combination with the advantages of biological aerated filters. Equipment and treatment methods, it has the advantages of no power, low construction cost, and the use of slope terrain according to local conditions. Solve the problems of facility construction and long-term operation.

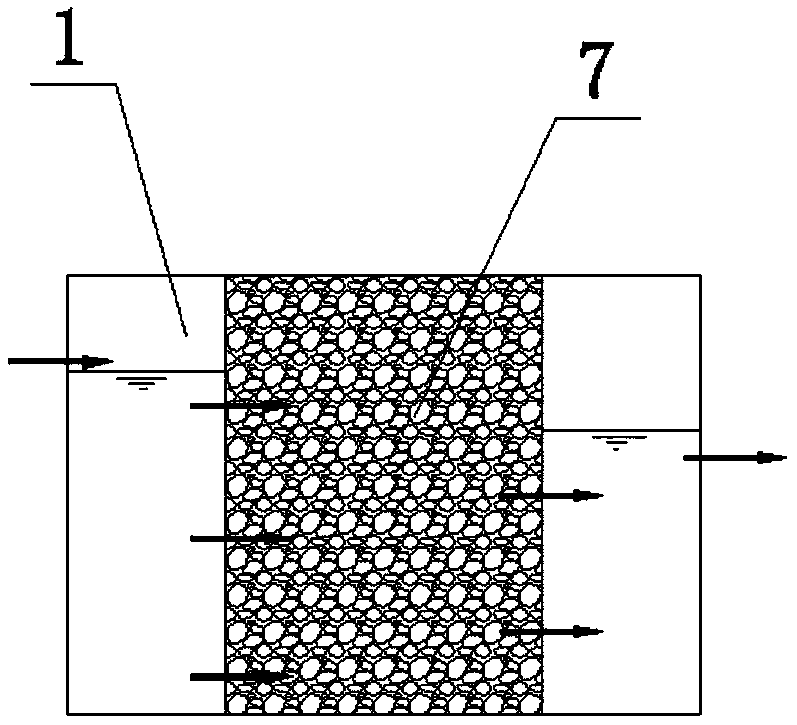

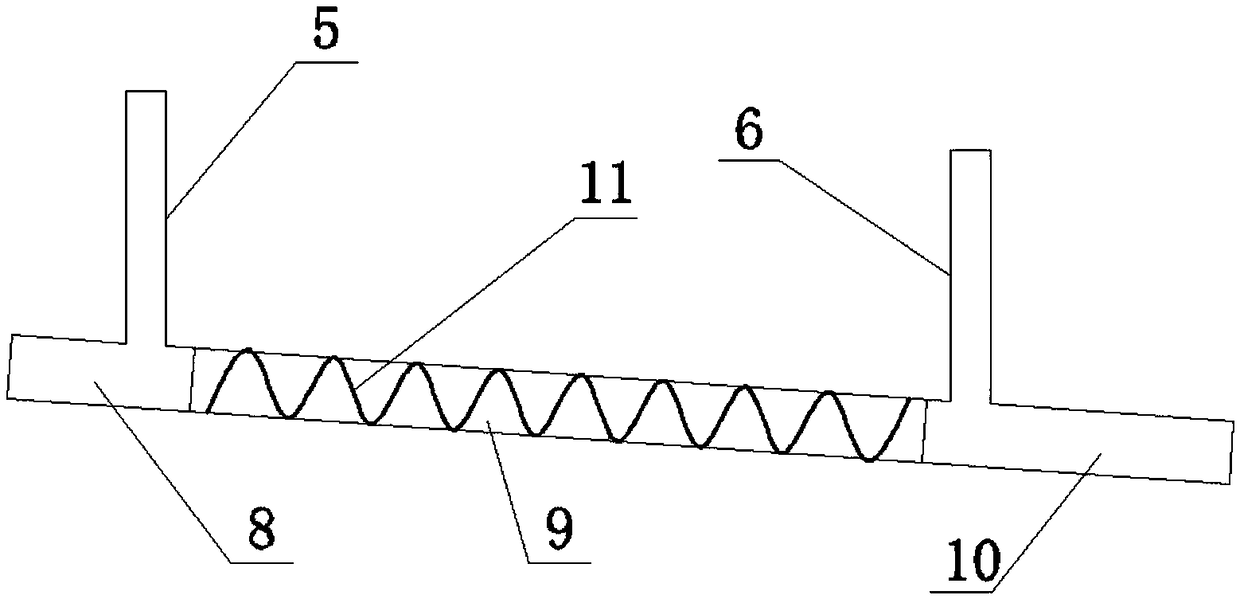

[0044] Such as Figure 1-4 As shown, a multi-stage tubular swirl oxygenation biological filter sewage treatment system is composed of a percolation tank 1, a swirl oxygenation tube 2, a biofilter 3 and a vertical flow sedimentation tank 4. The percolation tank 1 is filled with a percolation tank filter material layer 7; the swirling flow oxygenation pipe 2 is composed of a transition section 8, an oxygenation section 9 and a water d...

Embodiment 2

[0050] Embodiment 2 is basically the same as Embodiment 1, and the difference is that Embodiment 2 is a single-stage unpowered tubular cyclone oxygenated biological filter,

[0051] Such as Figure 5 As shown, the sewage treatment system of the tubular swirl oxygenation biological filter is composed of a percolation tank 1, a swirl oxygenation pipe 2, a biofilter 3 and a vertical flow sedimentation tank 4. The percolation tank 1 is filled with a percolation tank filter material layer 7; the swirling flow oxygenation pipe 2 is composed of a transition section 8, an oxygenation section 9 and a water distribution section 10, which are arranged according to the slope of the terrain, and the transition section is provided with an air outlet 5, The oxygenation section is provided with a swirling device 11, and the water distribution section 10 is provided with an air inlet 6; the biological filter 3 and the vertical flow sedimentation tank 4 are separated by a partition, and the bio...

Embodiment 3

[0053] A method for treating sewage in a multi-stage tubular swirling oxygenated biofilter, the steps of which are as follows:

[0054] A, according to embodiment 1 system construction described a kind of multi-stage tubular swirl oxygenation biofilter sewage treatment system;

[0055] B. Sewage enters the infiltration tank 1 from the water inlet pipe, passes through the filter material layer 7 of the infiltration tank, filters out suspended solids, and enters the swirl oxygenation pipe 2;

[0056] C, sewage in the swirl oxygenation pipe 2 swirl flow downwards through the swirl device 11, because the position and the air temperature at the air outlet 5 of the transition section of each swirl oxygenation pipe are higher than the water distribution section 10, so the air From the air inlet 6 of the water distribution section 10, it flows reversely along the pipeline to the air outlet 5 of the transition section 8, and in the oxygenation section 9, it is in convective contact wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com