A hydraulic start-stop device

A hydraulic and hydraulic pump technology, applied in the field of hydraulic start-stop devices, can solve the problems of engine fuel consumption and emission noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

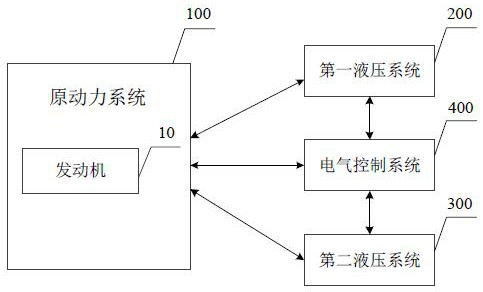

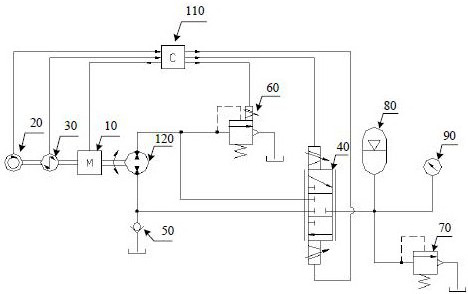

[0059] Such as figure 1 As shown, the first embodiment of the present invention proposes a hydraulic start-stop device, including a prime mover system 100, a first hydraulic system 200, a second hydraulic system 300 and an electrical control system 400, wherein the prime mover system 100 includes an engine 10 for providing Energy; the first hydraulic system 200 is connected with the prime mover system 100, and is used to transmit and convert the energy provided by the prime mover system 100, and to perform work and output energy to complete the expected action or function of the equipment; the second hydraulic system 300 and the prime mover system 100 It is used to absorb and store the energy of the prime mover system 100, and assist the drive of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com