Cooling method for mineral resource exploitation by means of natural cold source and application system thereof

A mineral resource and application system technology, applied in mine/tunnel ventilation, mining equipment, ground mining, etc., can solve problems such as unprofitability, affecting work efficiency, and low mine grade, so as to reduce equipment investment and cycle energy low energy consumption and running cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method of cooling in the mining of mineral resources by using natural cold sources, the process is:

[0032] (1) The surface water source is transported through the pipeline to the high and low pressure heat exchanger in the middle section of the underground excavation to exchange to form low pressure cold water; the high pressure hot water formed after the heat exchange is returned to the pool through the pipeline, forming a "U" curved siphon self-circulation system , the water in the pool is discharged to the surface water source according to the set liquid level range;

[0033] (2) The low-pressure cold water after heat exchange enters the cold water group through the downhole circulation pump, and the cold water group cools the air, and uses the original air supply system to deliver it to the operation face to cool it down.

[0034] The mechanism that heat exchange method of the present invention is used for the method for downhole operation cooling is:

[0035] ...

Embodiment 2

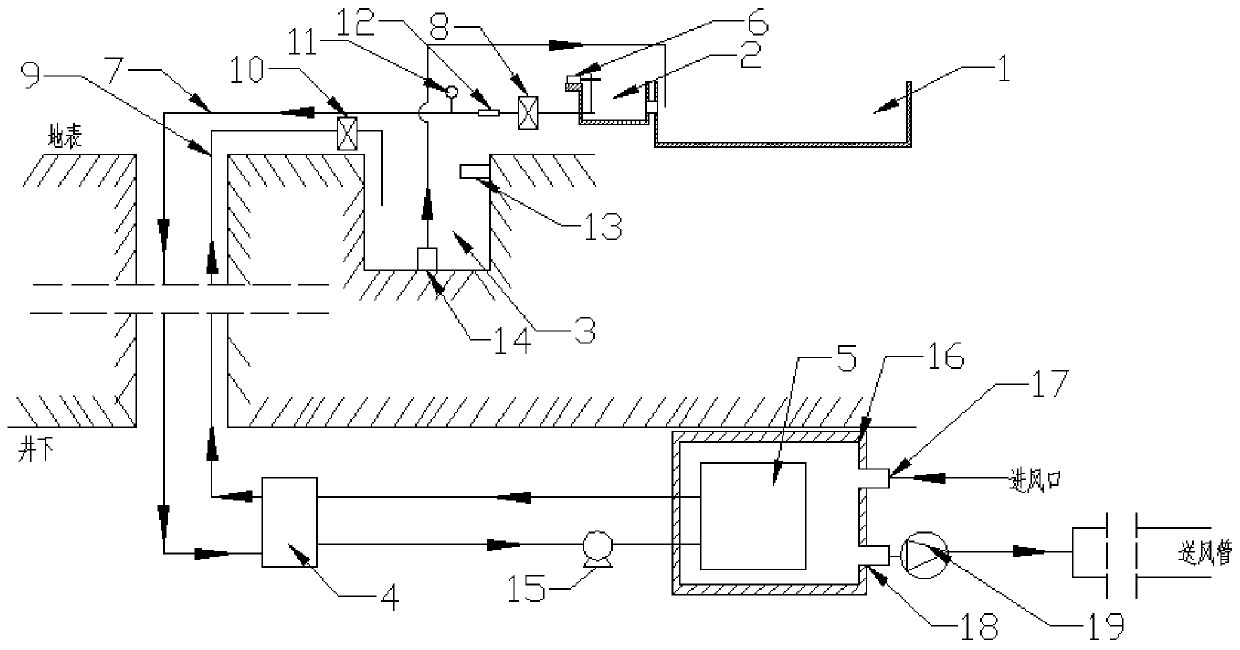

[0048] Such as Figure 1-Figure 2 As shown, the application system used in the cooling method of Example 1 includes a raw water tank 1, a buffer tank 2, a pool 3, a high and low pressure heat exchanger 4 and a cold water group 5;

[0049] The raw water tank 1, the buffer tank 2 and the pool 3 are located on the surface, and the high and low pressure heat exchanger 4 and the cold water group 5 are located underground;

[0050] The horizontal plane where the open end face of the pool 3 is located is lower than the horizontal plane where the bottom surface of the raw water tank 1 is located; this setting can make a potential difference between the raw water tank 1 and the pool 3;

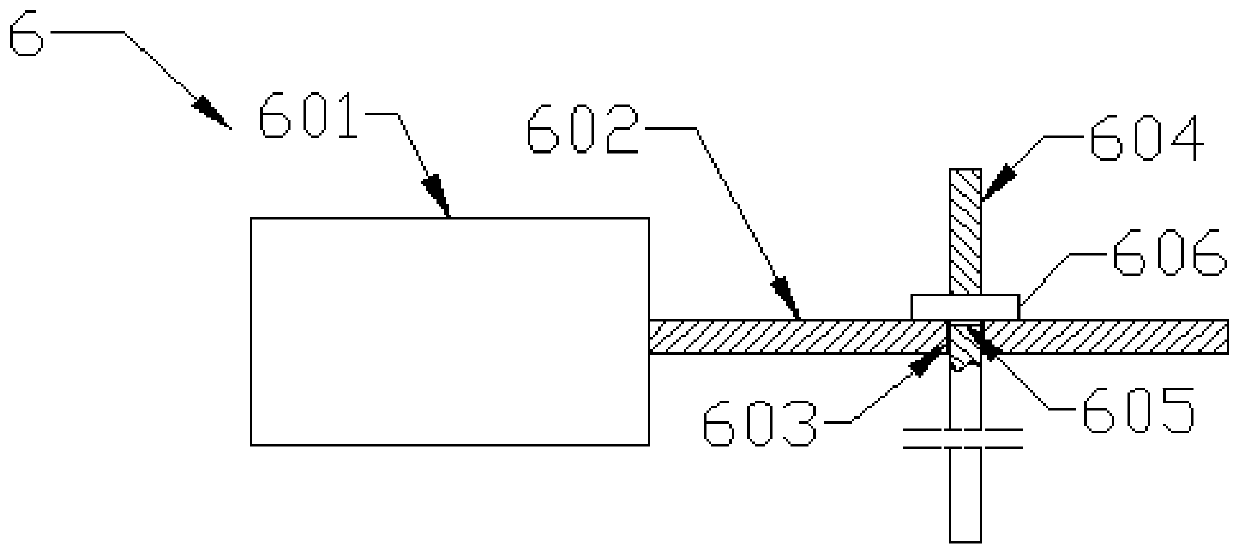

[0051] The raw water tank 1 is connected with the buffer tank 2, and the level of the bottom of the buffer tank 2 is higher than the level of the opening of the pool 3; the buffer tank 2 is provided with a lifting device 6, and the lifting device 6 can lift the pipeline A7 to facilitate filling The wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com