C-grade steel and heat treatment method thereof

A heat treatment method and weight fraction technology, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve problems such as unstable mechanical properties and affecting the service life of C-grade steel, and achieve the effect of stable low-temperature impact value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

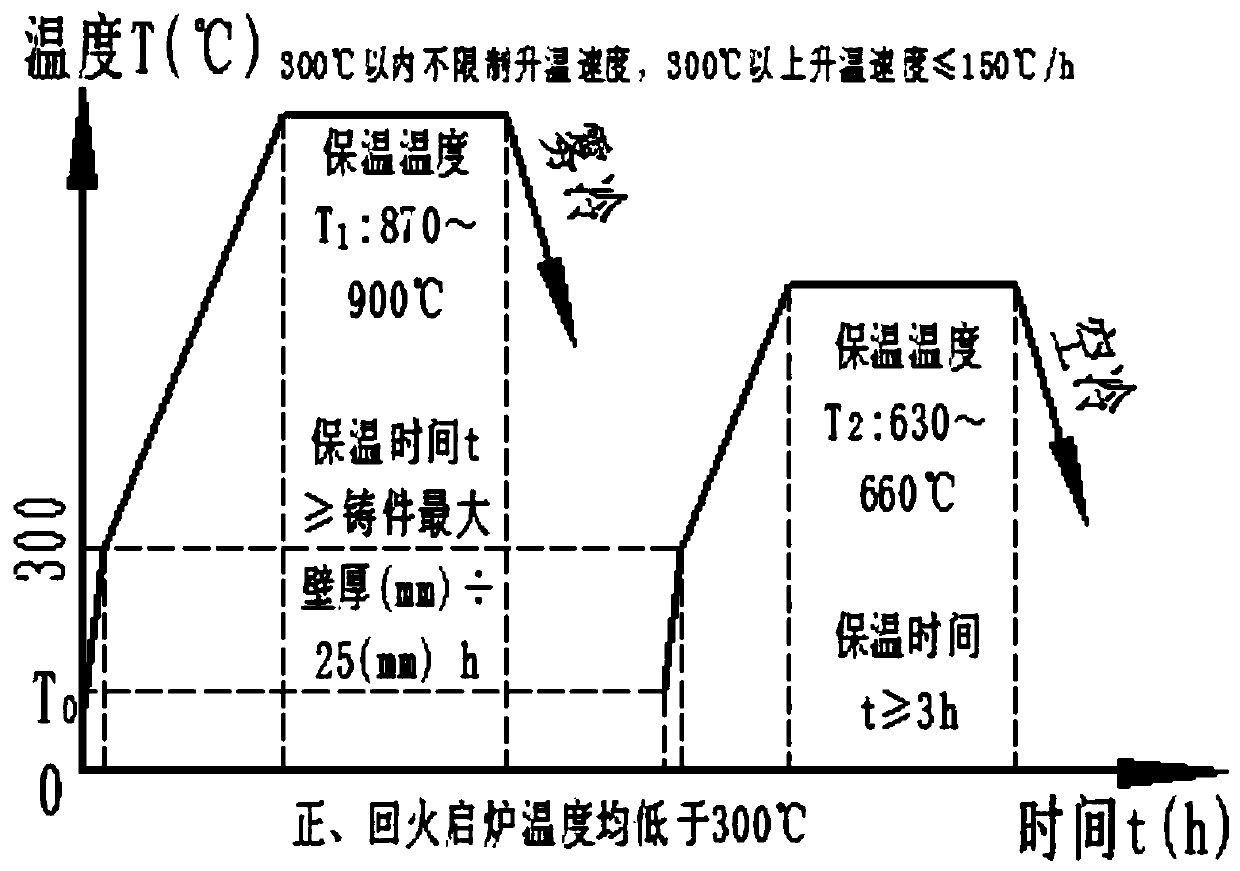

[0020] see figure 1 , including the following components by weight fraction: 0.26 parts of C, 0.39 parts of Si, 0.87 parts of Mn, 0.016 parts of P, 0.016 parts of S, 0.049 parts of Cu, 0.48 parts of Cr, and 0.14 parts of Mo.

[0021] The heat treatment method of the above grade C steel comprises the following steps:

[0022] a. Raise the temperature of Grade C steel to 870-900°C with the furnace at a rate of ≤150°C per hour, Fog cold.

[0023] b. Heat the grade C steel cooled to below 300°C to 630-660°C, hold the temperature for ≥3 hours, and cool in air.

[0024] As a preferred method, in steps a and b, the heating rate above 300°C is ≤150°C / h, and the heating rate is not limited within 300°C.

[0025] Specifically, the maximum wall thickness of the casting is 90mm.

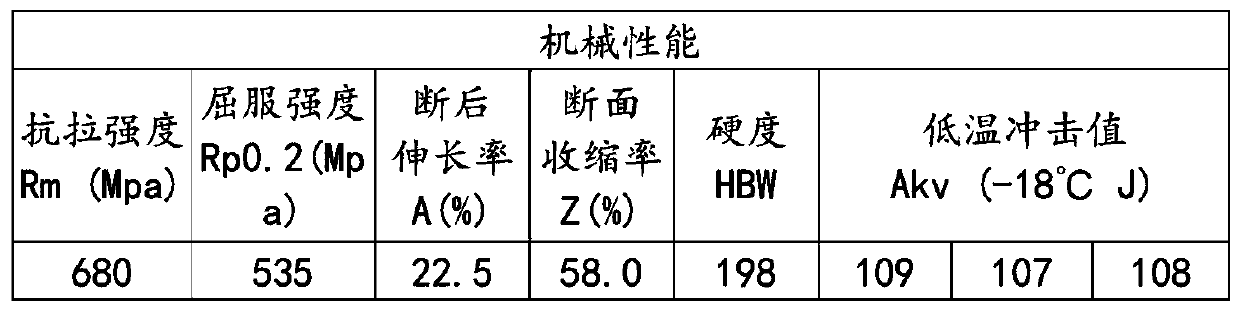

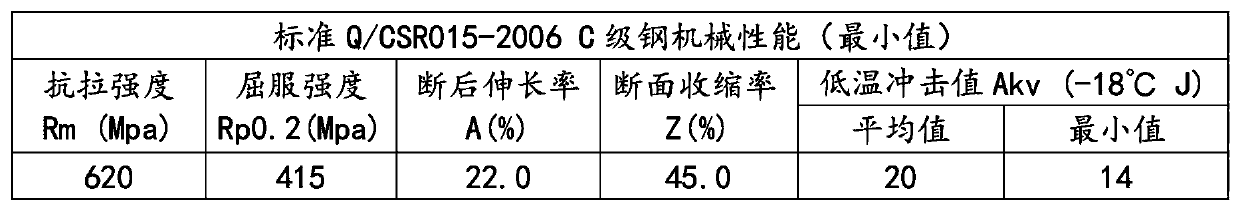

[0026] In this example, C made of 0.26 parts of C, 0.39 parts of Si, 0.87 parts of Mn, 0.016 parts of P, 0.016 parts of S, 0.049 parts of Cu, 0.48 parts of Cr, and 0.14 parts of Mo In the heat treatment ...

Embodiment 2

[0033] see figure 1 , including the following components by weight fraction: 0.27 parts of C, 0.4 parts of Si, 0.86 parts of Mn, 0.018 parts of P, 0.017 parts of S, 0.044 parts of Cu, 0.46 parts of Cr, and 0.15 parts of Mo.

[0034] The heat treatment method of the above grade C steel comprises the following steps:

[0035] a. Raise the temperature of Grade C steel to 870-900°C with the furnace at a rate of ≤150°C per hour, Fog cold.

[0036] b. Heat the grade C steel cooled to below 300°C to 630-660°C, hold the temperature for ≥3 hours, and cool in air.

[0037] As a preferred method, in steps a and b, the heating rate above 300°C is ≤150°C / h, and the heating rate is not limited within 300°C.

[0038] Specifically, the maximum wall thickness of the casting is 90mm.

[0039] In this example, C made of 0.27 parts of C, 0.4 parts of Si, 0.86 parts of Mn, 0.018 parts of P, 0.017 parts of S, 0.044 parts of Cu, 0.46 parts of Cr, and 0.15 parts of Mo In the heat treatment pr...

Embodiment 3

[0047] see figure 1 , including the following components by weight fraction: 0.28 parts of C, 0.37 parts of Si, 0.84 parts of Mn, 0.017 parts of P, 0.018 parts of S, 0.053 parts of Cu, 0.48 parts of Cr, and 0.15 parts of Mo.

[0048] The heat treatment method of the above grade C steel comprises the following steps:

[0049] a. Raise the temperature of Grade C steel to 870-900°C with the furnace at a rate of ≤150°C per hour, Fog cold.

[0050] b. Heat the grade C steel cooled to below 300°C to 630-660°C, hold the temperature for ≥3 hours, and cool in air.

[0051] As a preferred method, in steps a and b, the heating rate above 300°C is ≤150°C / h, and the heating rate is not limited within 300°C.

[0052] Specifically, the maximum wall thickness of the casting is 90mm.

[0053] In this example, C made of 0.28 parts of C, 0.37 parts of Si, 0.84 parts of Mn, 0.017 parts of P, 0.018 parts of S, 0.053 parts of Cu, 0.48 parts of Cr, and 0.15 parts of Mo In the heat treatment pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com