Biogas fermentation tank heat-tracing heating constant temperature device and application method thereof

A biogas fermentation and constant temperature device technology, applied in bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical cleaning device, etc. The problems of poor performance and inactivation of methanogens can achieve the effect of optimizing the disturbance in the tank, reducing investment and maintenance costs, and reducing heating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The purpose of the present invention is to improve the problems of large heat loss in the existing fermentation device, easy fouling of the heating tube that affects the heat exchange efficiency, etc., and when the heating tube is not in direct contact with the fermentation liquid, it can realize the temperature increase outside the tank and the inside of the tank. , middle and lower part of the optimal arrangement for uniform heating.

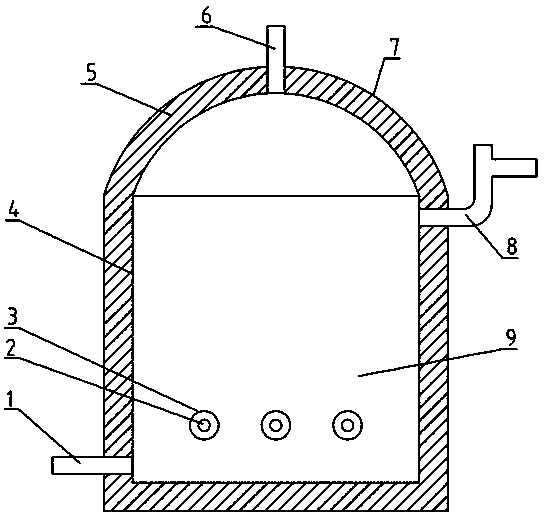

[0030] The anaerobic fermenter electric heat tracing temperature increasing constant temperature device is composed of a fermenter, an electric heating element 2, a feed pipe 1, a heating pipe 3, an insulation layer 5 and the like.

[0031] The principle of the present invention is: the heating pipe 3 is made of stainless steel material with good thermal conductivity, the inside is fixed on the bottom of the fermenter 4, the fermenter 4 is provided with an insulating layer 5 to reduce the heat loss of the fermenter 4, and the insulating ...

Embodiment 2

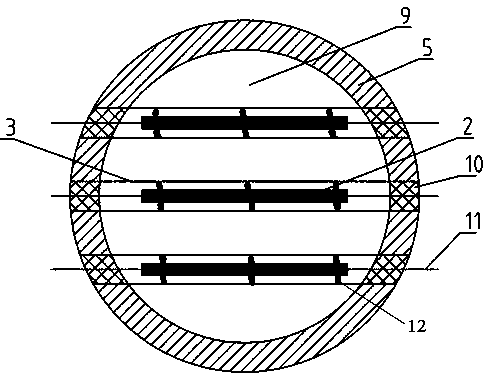

[0037] The tank body is composed of an inner tank body with a diameter of 5m and a height of 5m. The internal medium of the tank body is water, and the wall thickness of the tank body is negligible. The outer thickness of the tank body is 1m. The arrangement method is that the heating pipes are arranged horizontally at a height of 1m from the bottom of the tank, the distance between the three pipes is 1.25m, and the heating volume heat release rate of the pipes is 4500W / m 3 .

Embodiment 3

[0039] An anaerobic fermentation tank heat tracing temperature increasing constant temperature device, comprising a fermentation tank 4, a feed pipe 1, a biogas pipe 6 and an overflow discharge pipe 8 are arranged on the fermentation tank 4, an insulation layer 5 is arranged on the outer wall of the fermentation tank 4, and the fermentation tank 4 is provided with an insulation layer 5. A plurality of stainless steel heating tubes 3 are added at the inner bottom of the tank 4, and armored heating elements are embedded in the heating tubes 3. The stainless steel heating tubes 3 are circular tubes, and the outer wall and the inner wall of the fermentation tank 4 form an anaerobic fermentation zone; the heating tubes 3 The inner wall is in contact with the heating element.

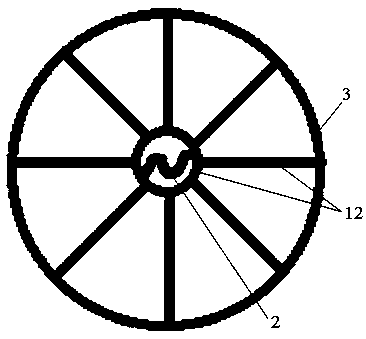

[0040] The heating element is fixedly arranged on the heat transfer support 12. The middle of the heat transfer support 12 is a ring surrounded by evenly arranged ribs. The heating element is fixed in the ring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com