Water-based fluff paint containing negative oxygen ions and preparation method thereof

A technology of negative oxygen ions and deionized water, applied in coatings, fireproof coatings, etc., can solve the problems of poor adhesion between layers, peeling, wrong curing agent, etc., and achieve the effect of high reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

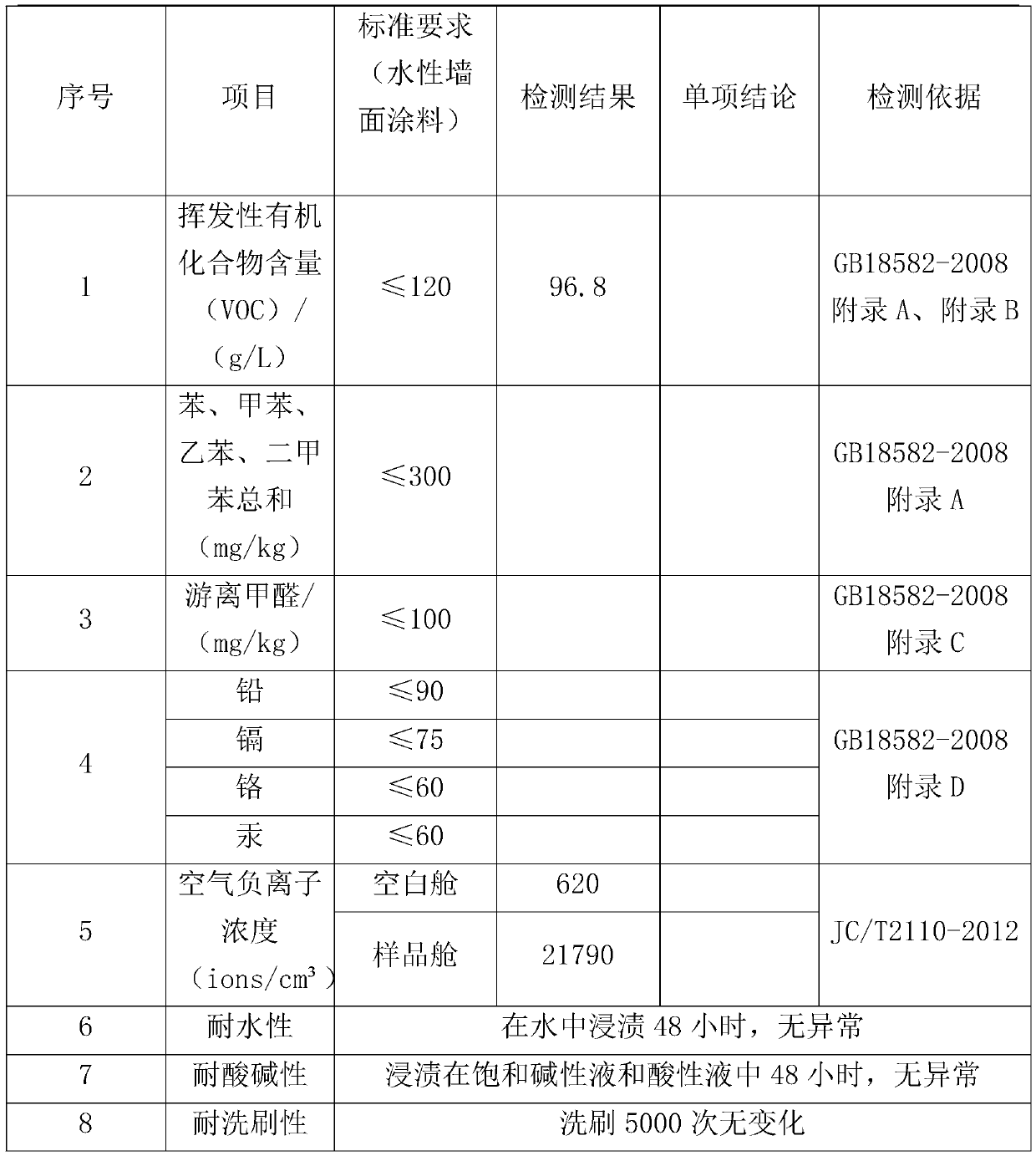

Embodiment 1

[0043] A water velvet paint containing negative oxygen ions is prepared from the following raw materials:

[0044] Elastic emulsion: 50kg

[0045] Primer: 3kg

[0046] Wetting agent: 0.3kg

[0047] Defoamer: 0.2kg

[0048] Film-forming aids: 3kg

[0049] Thickener: 1.2kg

[0050] Negative oxygen ion: 20kg

[0051] Fluff powder: 15kg

[0052] Deionized water: 1.3kg;

[0053] The elastic emulsion is selected from methyl acrylate, ethyl acrylate and silicone copolymer;

[0054] The primer is selected from talcum powder with a particle size of 1000-1200 mesh;

[0055] The wetting agent is selected from alkyl sulfate anionic surfactants;

[0056] The defoamer is selected from polyether defoamers;

[0057] Described film-forming aid is selected from propylene glycol methyl ether acetate;

[0058] The thickener is selected from water-soluble polyacrylate thickeners;

[0059] The negative oxygen ion is selected from the liquid negative ion liquid in bamboo;

[0060] The f...

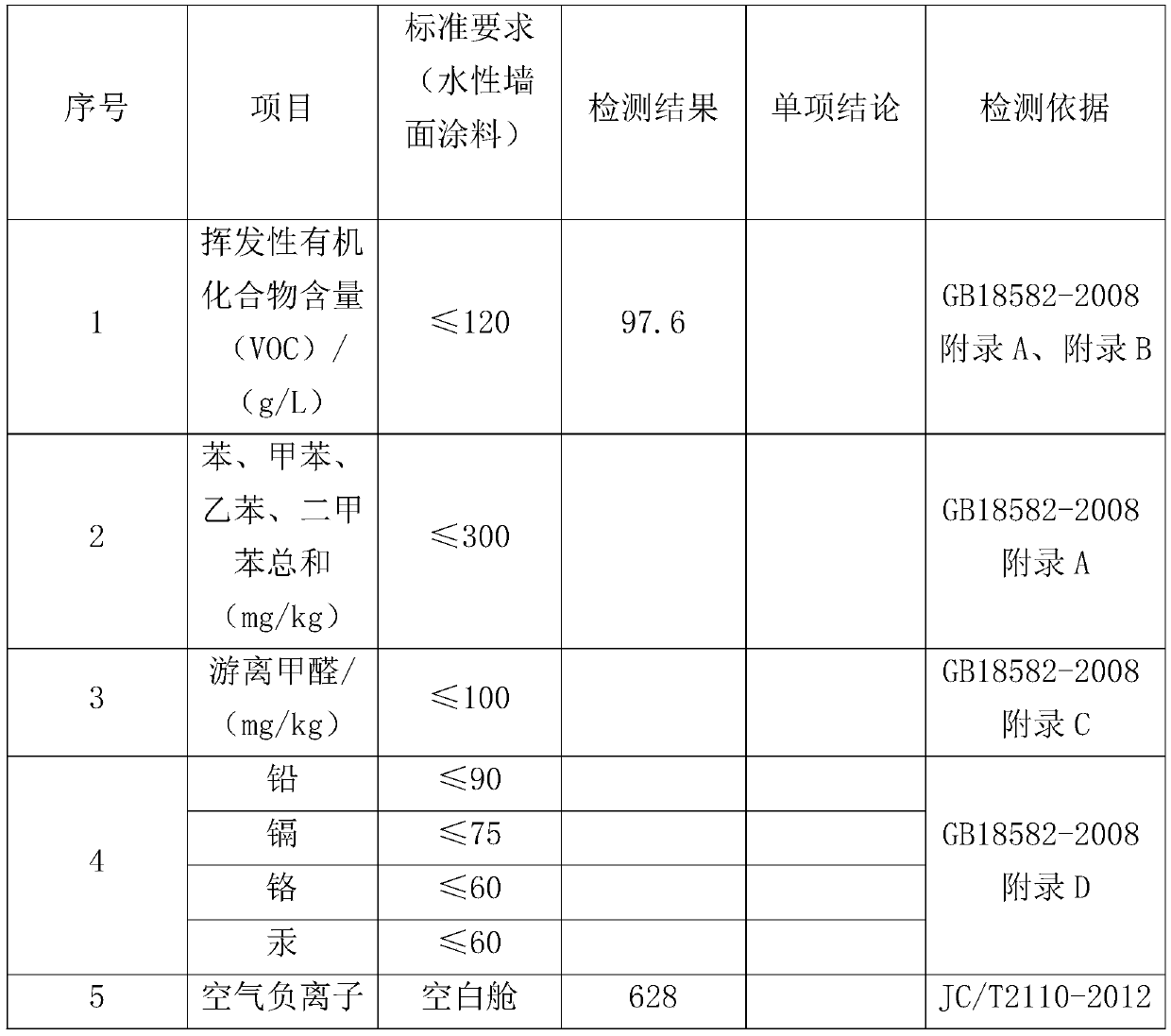

Embodiment 2

[0071] A water velvet paint containing negative oxygen ions is prepared from the following raw materials:

[0072] Elastic emulsion: 53kg

[0073] Primer: 3.5kg

[0074] Wetting agent: 0.35kg

[0075] Defoamer: 0.25kg

[0076] Film-forming aids: 4kg

[0077] Thickener: 2kg

[0078] Negative oxygen ion: 17kg

[0079] Fluff powder: 16kg

[0080] Deionized water: 1.5kg;

[0081] The elastic emulsion is selected from 2-methyl methacrylate, 2-ethyl methacrylate and silicone copolymer;

[0082] The primer is selected from talcum powder with a particle size of 1000-1200 mesh;

[0083] The wetting agent is selected from fatty acid ester sulfate anionic surfactants;

[0084] The defoamer is selected from polyether defoamers;

[0085] Described film-forming aid is selected from propylene glycol methyl ether acetate;

[0086] The thickener is selected from water-soluble polyacrylate thickeners;

[0087] The negative oxygen ion is selected from the liquid negative ion liquid i...

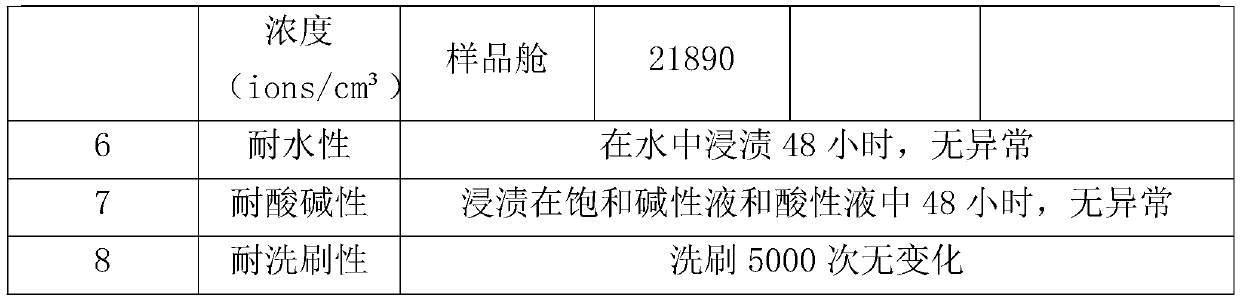

Embodiment 3

[0100] A water velvet paint containing negative oxygen ions is prepared from the following raw materials:

[0101] Elastic emulsion: 56kg

[0102] Primer: 5kg

[0103] Wetting agent: 0.5kg

[0104] Defoamer: 0.35kg

[0105] Film-forming aids: 6kg

[0106] Thickener: 3kg

[0107] Negative oxygen ion: 30kg

[0108] Fluff powder: 20kg

[0109] Deionized water: 1.8kg;

[0110] The elastic emulsion is selected from ethyl acrylate, 2-ethyl methacrylate and silicone copolymer;

[0111] The primer is selected from talcum powder with a particle size of 1000-1200 mesh;

[0112] The wetting agent is selected from carboxylic acid soap anionic surfactants;

[0113] The defoamer is selected from polyether defoamers;

[0114] Described film-forming aid is selected from propylene glycol methyl ether acetate;

[0115] The thickener is selected from water-soluble polyacrylate thickeners;

[0116] The negative oxygen ion is selected from the liquid negative ion liquid in bamboo;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com