Construction waste recycling and brick making equipment

A technology for construction waste and equipment, which is applied in the field of construction waste recycling brick making equipment, can solve the problems of large labor demand, large space occupation, and many steps, and achieves a brick making process with simple and practical procedures, labor saving, and high degree of crushing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

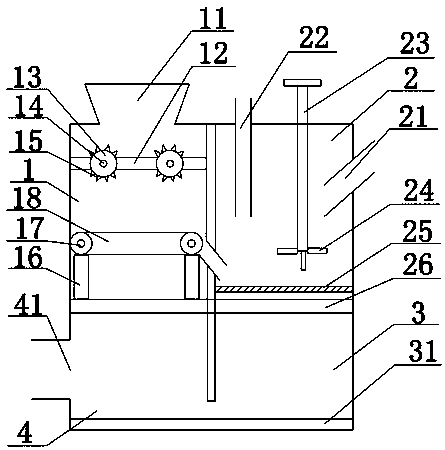

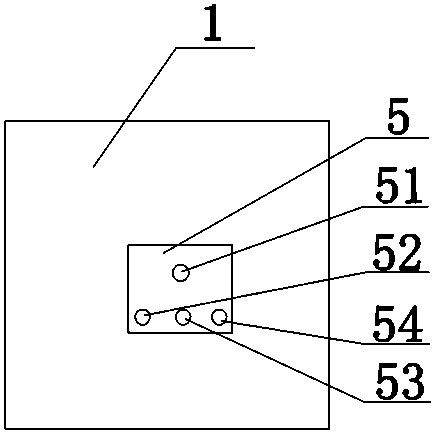

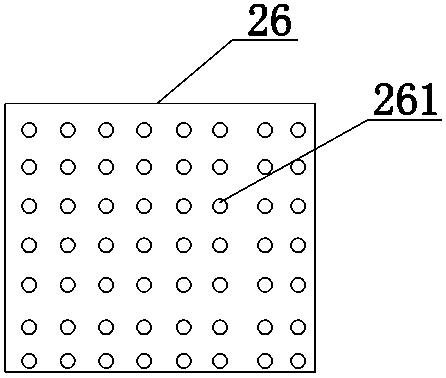

[0016] See Figure 1-Figure 3 As shown, the technical scheme adopted in this specific embodiment is that it includes a crushing bin 1, a feed port 11, a fixed rod 12, a crushing device 13, a rotating shaft 14, a crushing hammer 15, a support rod 16, a runner 17, a conveyor belt 18. Mixing chamber 2, feeding port 21, water inlet 22, rocking handle 23, stirring rod 24, screen 25, partition 26, round hole 261, brick forming machine 3, conveyor belt 31, brick stacking machine 4, discharge Port 41, control panel 5, main switch 51, crushing button 52, forming button 53, superimposing button 54, inside the crushing chamber 1 is provided with a fixed rod 12, a crushing device 13, a rotating shaft 14, a crushing hammer 15, and a support The rod 16, the runner 17, the conveyor belt 18, the upper side of the support rod 16 is fixed with runners 17 on both sides, the runner 17 is connected with the conveyor belt 18, the fixed rods 12 are welded on the left and right sides of the inside of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com