Rapid stirring device for preparing monoclinic lead tungstate nanobelt crystal material

A monoclinic lead tungstate, crystal material technology, applied in nanotechnology, mixer accessories, tungsten compounds, etc., can solve the problems of inconsistent mixing degree, poor fluidity, affecting mixing quality, etc. The effect of improving mixing efficiency and mixing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

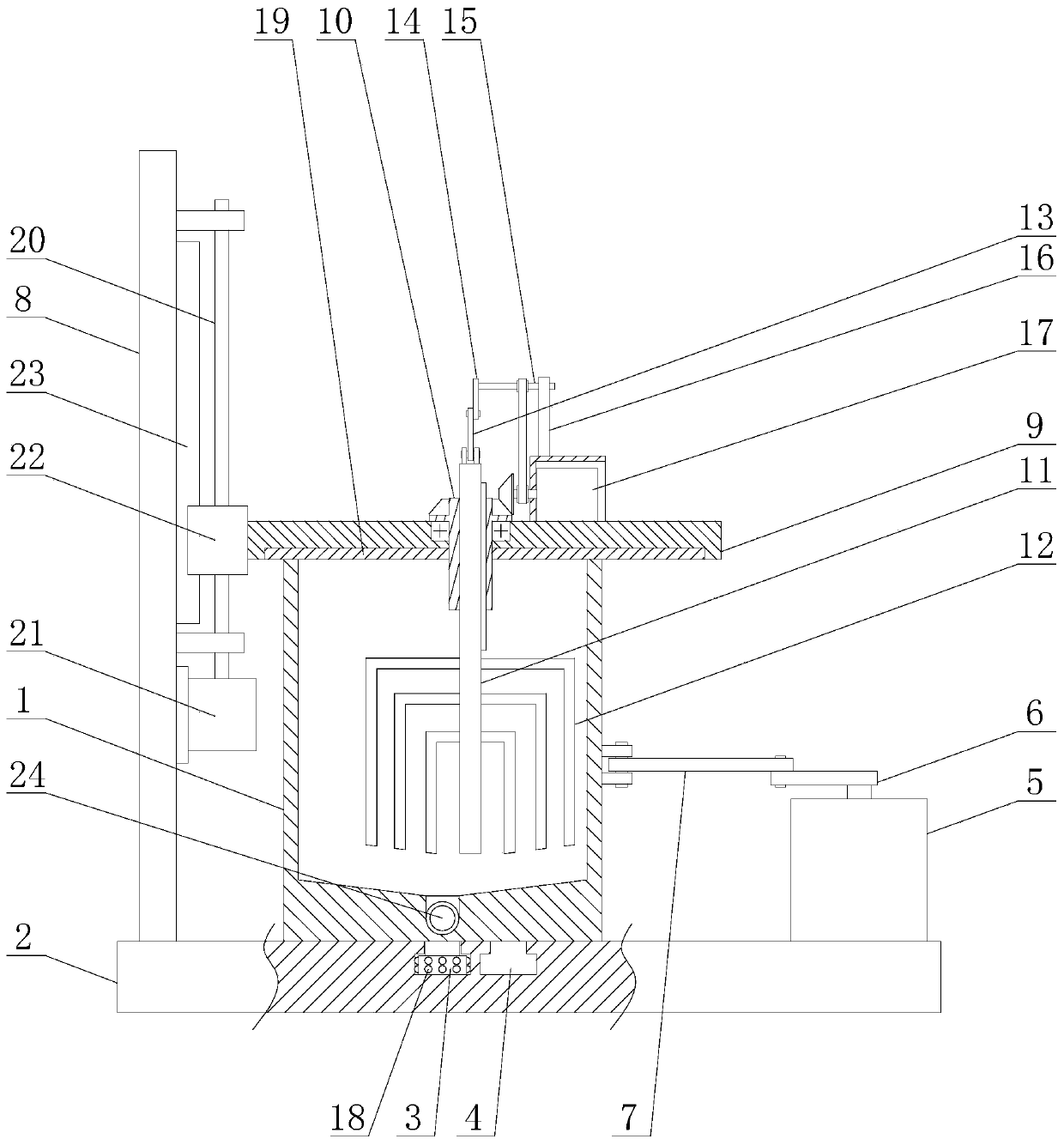

[0016] Example: as attached figure 1 As shown, the present invention is a rapid stirring device for the preparation of monoclinic lead tungstate nanoribbon crystal material, comprising a stirring barrel 1, a support seat 2, and the stirring barrel 1 is a barrel with an open top, for To facilitate the discharge of the raw materials after stirring, the bottom surface in the mixing tank body 1 is arranged in a funnel shape, and the middle part of the bottom of the mixing tank body 1 is provided with a discharge pipe 24 extending outwards from the mixing tank body 1, so The discharge pipe 24 is provided with a valve. Further, in order to heat simultaneously during stirring, a heating device is provided on the outer wall of the stirring barrel 1 . The bottom of the mixing barrel 1 is provided with a slider 3 , and the top of the support base 2 is provided with an annular chute 4 compatible with the slider 3 , and the agitating barrel 1 can slide along the annular chute 4 . Prefer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com