Aerosol atomizer capable of preventing tar leakage and repeated tar injection and electronic cigarette comprising same

An anti-repetition and aerosol technology, applied to tobacco and other fields, can solve the problems of oil leakage, downward seepage, and limited ability to absorb smoke oil from the components of the atomizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with examples, but the present invention is not limited in any way, and any transformation or substitution made based on the teaching of the present invention belongs to the protection scope of the present invention.

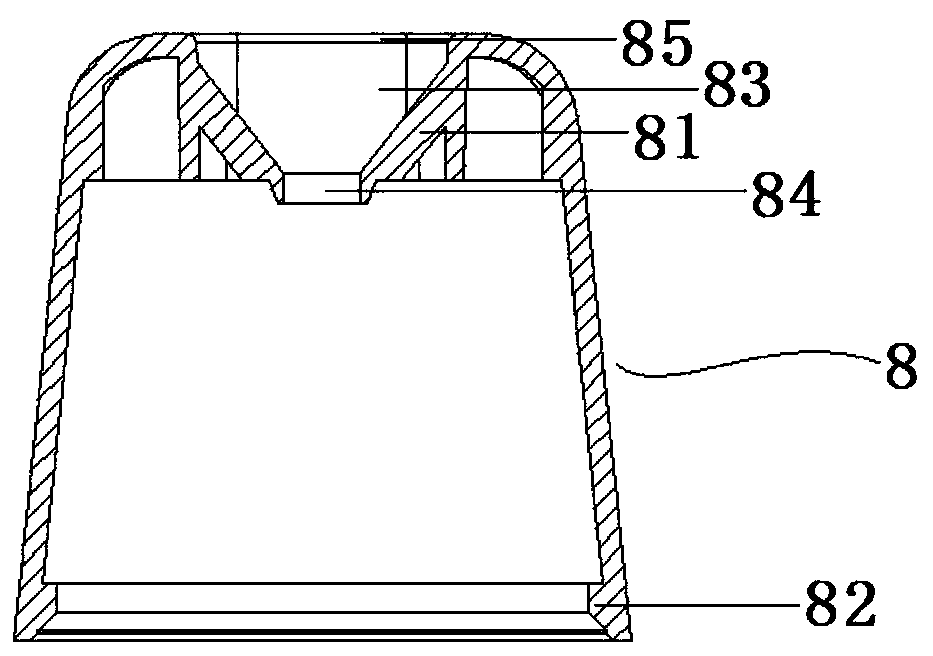

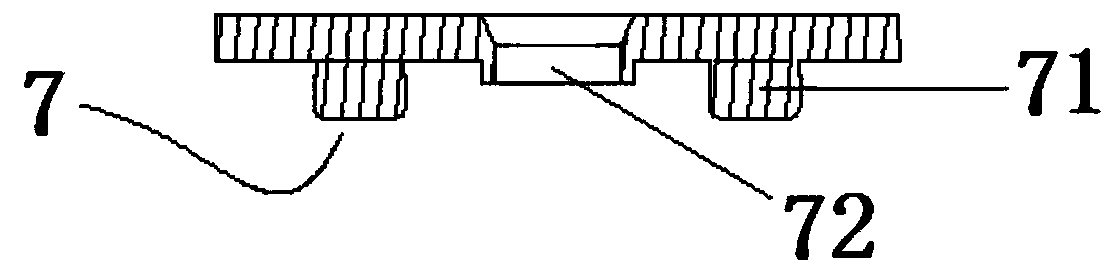

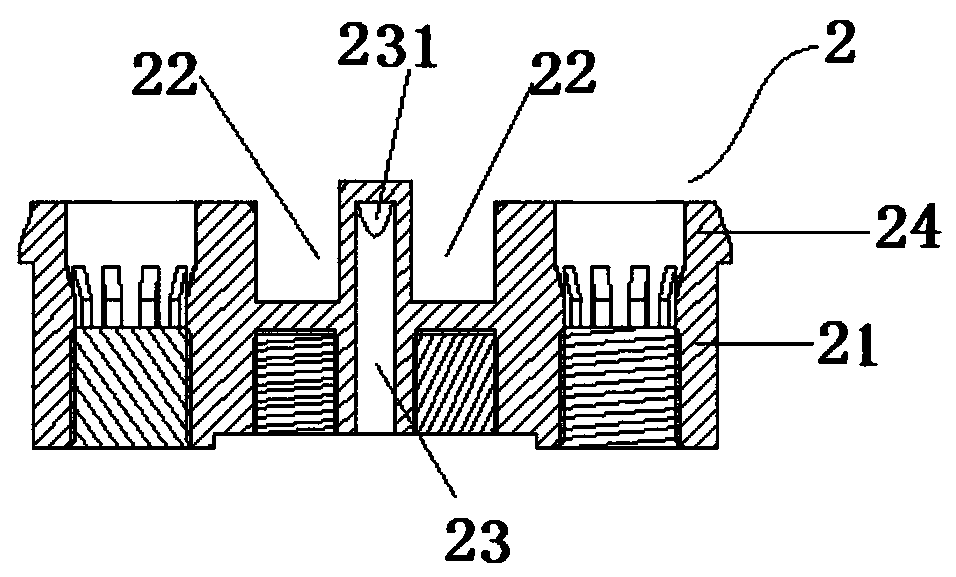

[0052] This embodiment is an electronic cigarette that prevents oil leakage and refilling, and the aerosol atomizer used in it includes:

[0053] The casing 1 has an oil injection hole 12 downstream of the casing 1, which communicates with the oil storage bin 13 inside the casing 1; the downstream interior of the casing 1 has a first aerosol channel 11, and the side wall of the casing 1 is from upstream to downstream There are first clamping hole 14, second clamping hole 15 and third clamping hole 16 in sequence;

[0054] The first pipe body 3 is located inside the shell 1, has an oil inlet hole 31 on its side wall, and has an atomizing core 32 and an oil-conducting cotton 33 inside;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com