Masson pine 'paper pulp-rosin extraction' mode middle-term rosin extraction method

A masson pine and pulp technology, applied in horticultural methods, botanical equipment and methods, chemicals for biological control, etc. Absorb and realize the effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

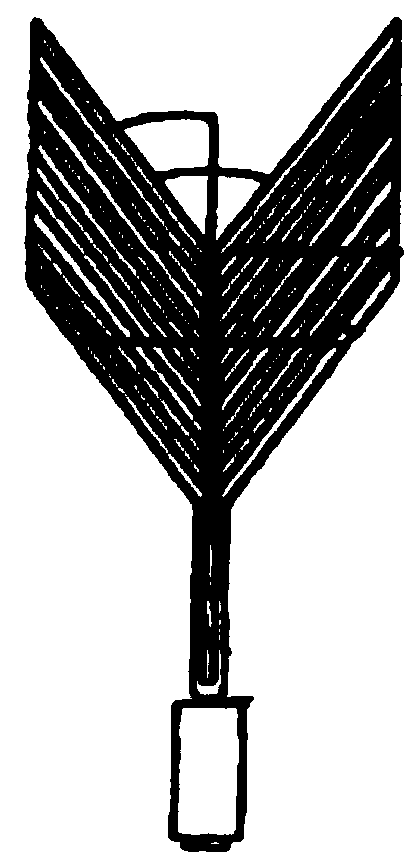

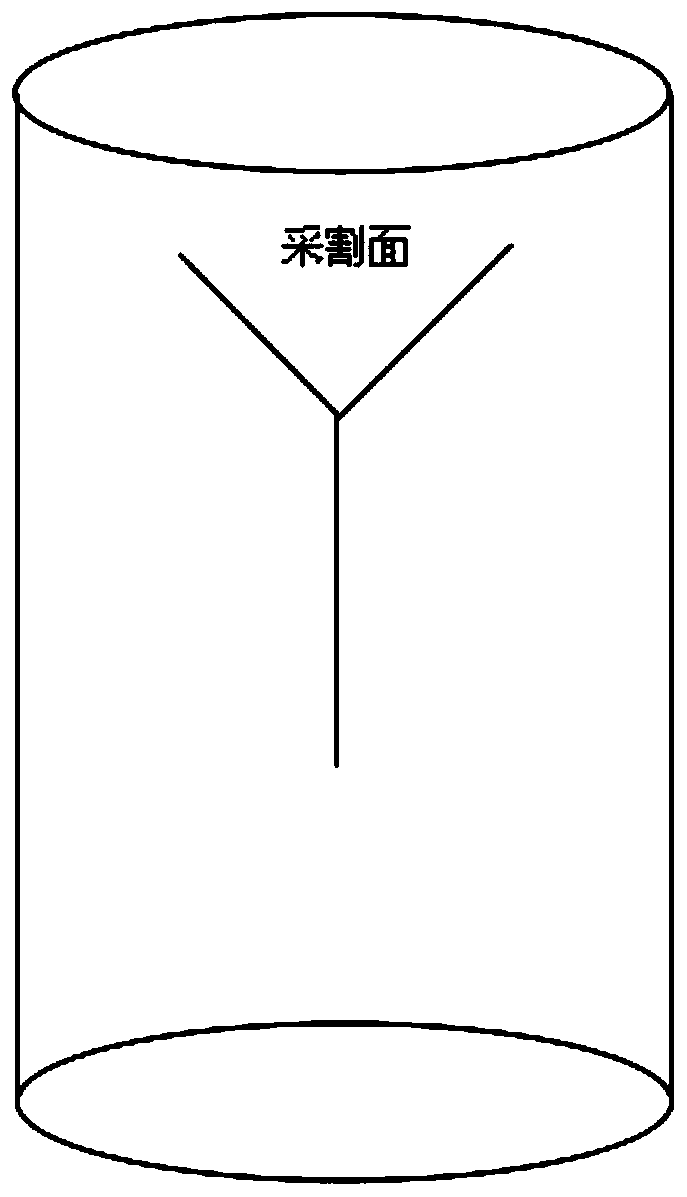

[0042] like figure 1 , 2 , 3, a method for masson pine "pulp material-fat extraction" mode medium-term fat extraction, comprising the following steps:

[0043] (1) In the Bajiaoshan subfield of Tianhongling Forest Farm in Cangwu County, a 15-year-old Masson pine with a DBH of 19.2cm was selected, and on the upper slope of the tree, resin was harvested by descending double-sided trenches from the ground to the tree height of 1.9m Fat harvesting method, the fat harvesting load rate is 63%, the harvesting circumference is 37.4cm, the width of the nutrient band is 23cm, the single included angle is 30 degrees, the cutting groove is 0.3cm deep into the xylem, and the step distance is 0.1cm. It is harvested once a day, each time with a watering can 2ml of fat-increasing agent is sprayed onto the newly cut wound surface, and the fat-increasing agent, in parts by weight, includes the following raw materials: 50 parts of lysine, 3 parts of magnesium chloride, 2 parts of zinc nitrate, ...

Embodiment 2

[0050] like figure 1 , 2 , 3, a method for masson pine "pulp material-fat extraction" mode medium-term fat extraction, comprising the following steps:

[0051] (1) In the Bajiaoshan subfield of Tianhongling Forest Farm in Cangwu County, a 15-year-old Pinus massoniana with a DBH of 19 cm was selected. On the upper slope of the tree, the resin was harvested by descending double-side trenches from the ground to the tree height of 2m. Fat, the fat harvesting load rate is 62%, the harvesting circumference is 36.9cm, the width of the nutrient band is 22cm, the single included angle is 30 degrees, the cutting ditch is 0.3cm deep into the xylem, and the step distance is 0.1cm. Grease agent 2ml is sprayed to newly cut wound surface, and described fat enhancer, in weight part, comprises following raw material: 50 parts of lysine, 3 parts of magnesium chloride, 2 parts of zinc nitrate, 2 parts of ferric chloride, copper nitrate 1 part, 0.6 part of borax, 4 parts of sodium chloride, 1 p...

Embodiment 3

[0058] like figure 1 , 2 , 3, a method for masson pine "pulp material-fat extraction" mode medium-term fat extraction, comprising the following steps:

[0059] (1) In the Bajiaoshan Branch of Tianhongling Forest Farm in Cangwu County, a 15-year-old Masson pine with a DBH of 20.4cm was selected, and the tree was harvested from the ground to the tree height of 2.1m on the upper slope of the tree by descending double-sided furrows. Fat harvesting method, the fat harvesting load rate is 65%, the harvesting circumference is 41.6cm, the width of the nutrient band is 22cm, the single included angle is 30 degrees, the cutting groove is 0.3cm deep into the xylem, and the step distance is 0.1cm. It is harvested once a day, and each time it uses a watering can 2ml of fat-increasing agent is sprayed onto the newly cut wound surface, and the fat-increasing agent, in parts by weight, includes the following raw materials: 50 parts of lysine, 3 parts of magnesium chloride, 2 parts of zinc ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com