A device for generating plasma water vapor based on the principle of ejection

A plasma and generating device technology, applied in the field of plasma water vapor generating device, can solve the problems of unfavorable energy saving and environmental protection, heat loss, large volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

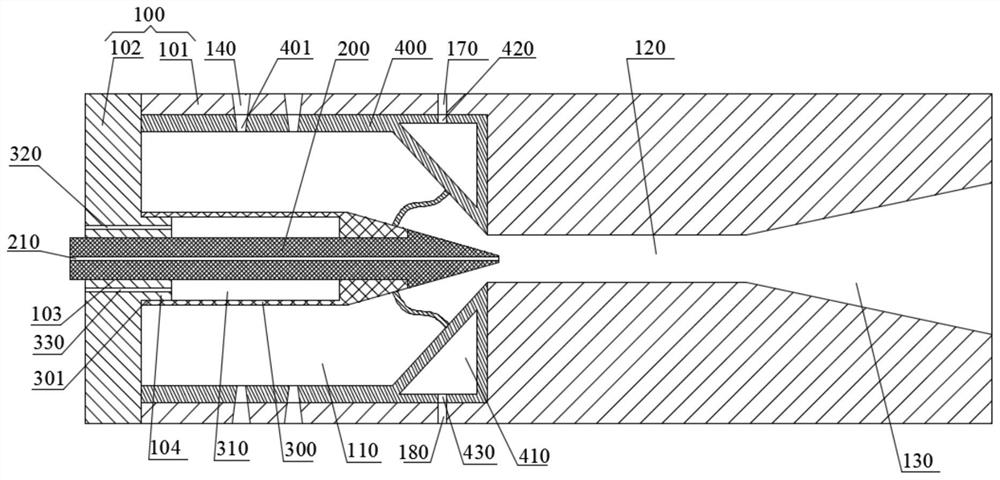

[0028] Such as figure 1As shown, the embodiment of the present application provides a plasma steam generating device based on the principle of ejection, which includes an ejector body 100 made of polyphenylene sulfide material, and the ejector body 100 includes a body 101 and a body 101 An annular end cap 102 connected at one end, the body 101 is provided with a throat channel 120 and a diffusion channel 130 connected in sequence, the inner diameter of the diffusion channel 130 gradually increases as it moves away from the throat channel 120, and the diffusion channel 130 communicates with the throat channel 120 and the Outside the body 101, the end cap 102 and the end of the body 101 enclose and form a suction chamber 110 communicating with the throat channel 120. The middle part of the end cap 102 is provided with a through hole 103, and the end cap 102 is connected with a polyphenylene sulfide material. The finished nozzle 200, one end of the nozzle 200 passes through the t...

Embodiment 2

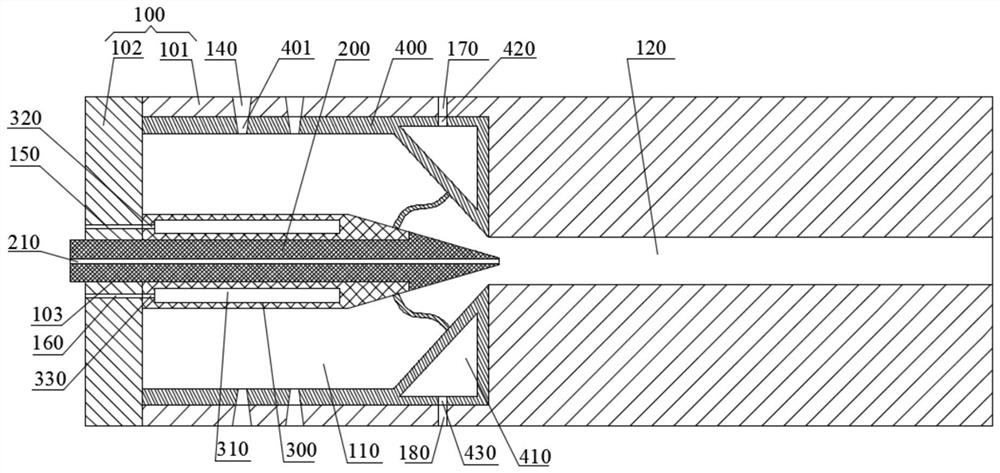

[0032] Such as figure 2 As shown, the embodiment of the present application provides a plasma water vapor generation device based on the principle of ejection, which has roughly the same structure as the plasma water vapor generation device based on the principle of ejection provided in Example 1, the difference is that this embodiment In the ejector body 100, there is no diffusion channel 130, one end of the throat channel 120 is connected to the suction chamber 110, and the other end is connected to the outside of the ejector body 100, the end cap 102 is not provided with a stopper 104, and the anode 300 is provided with There is a first cooling chamber 310 and a first liquid inlet hole 320 and a first liquid outlet hole 330 communicating with the first cooling chamber 310, and the end cover 102 is provided with a first cooling inlet connecting the first liquid inlet hole 320 and the outside 150 and the first cooling outlet 160 connecting the first liquid outlet 330 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com