Pipeline laying device for building construction

A technology for building construction and laying equipment, applied in pipeline laying and maintenance, auxiliary equipment, metal processing equipment, etc., can solve the problems of slow process, large volume, affecting the efficiency of pipeline laying, etc., to improve the process of pipeline welding, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

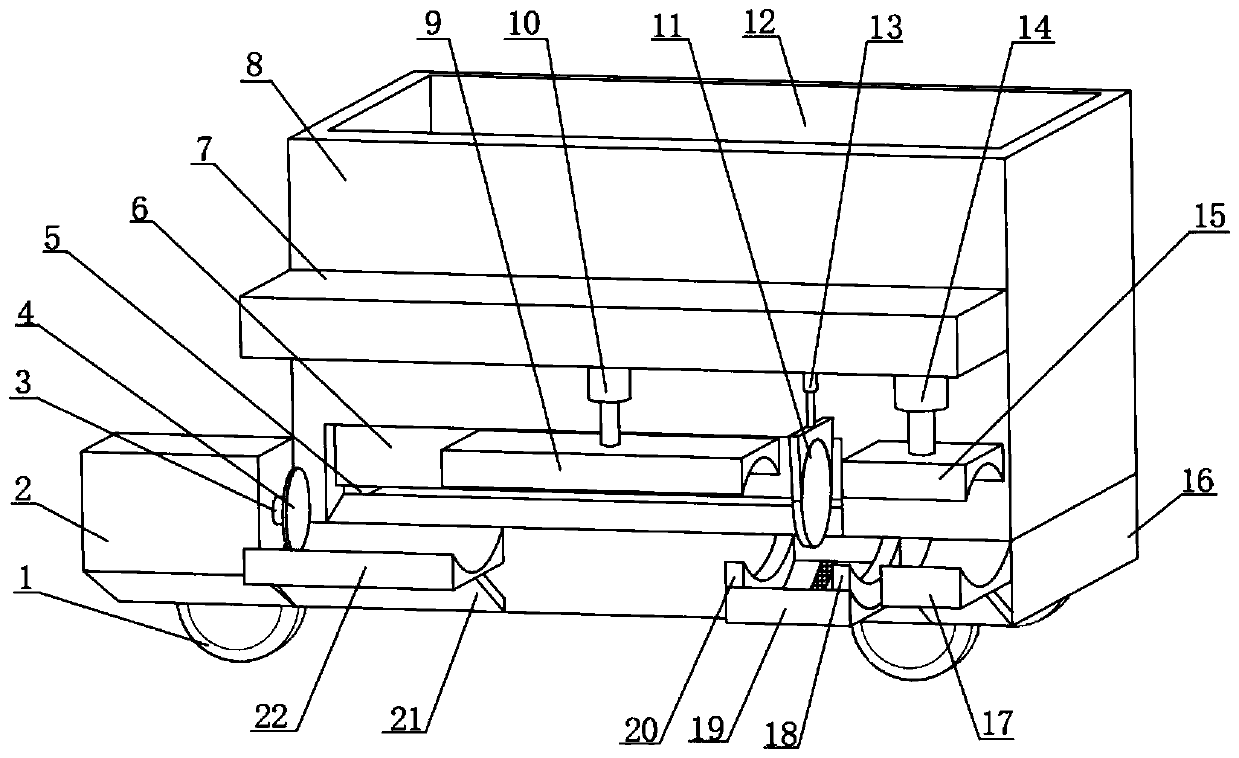

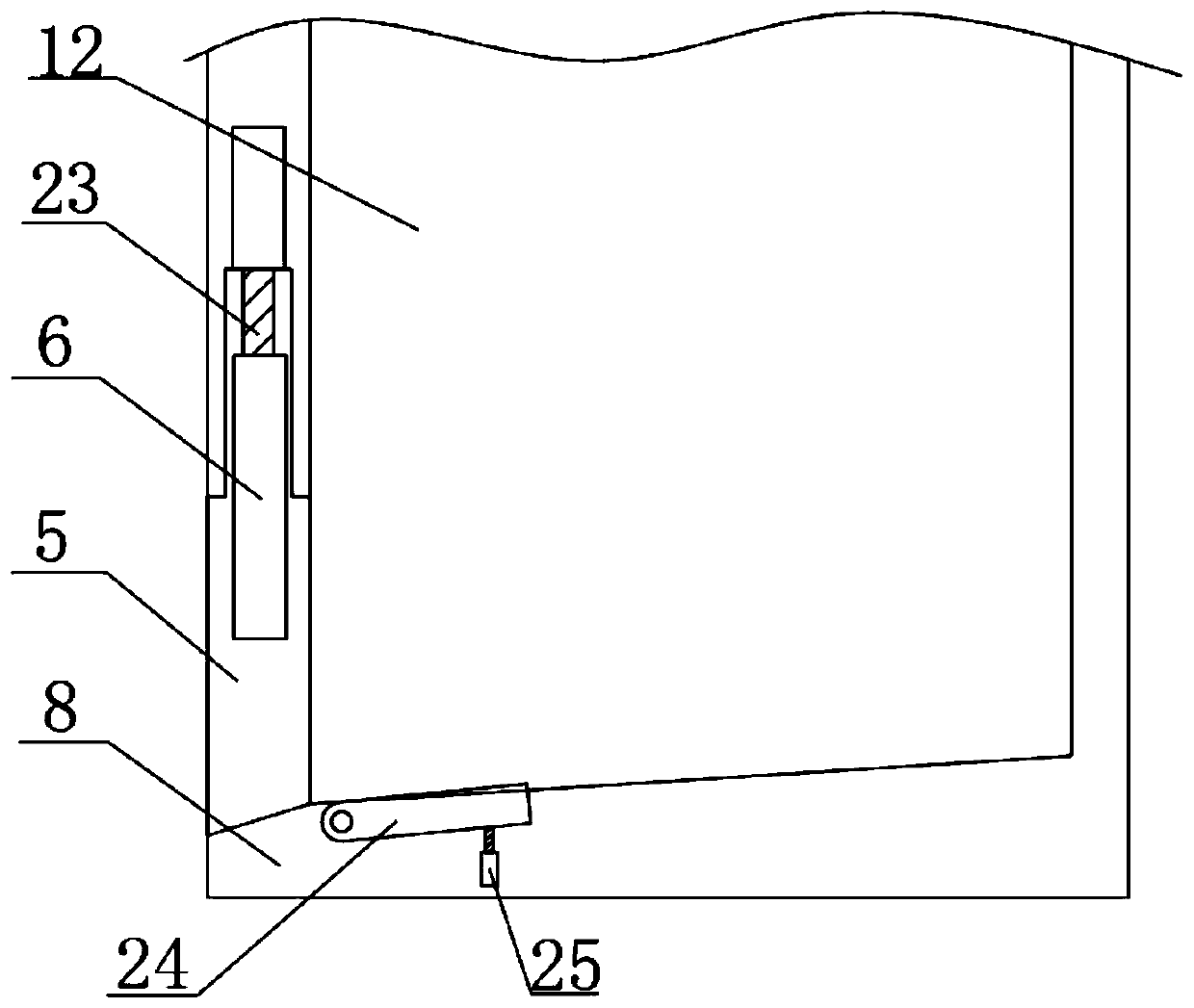

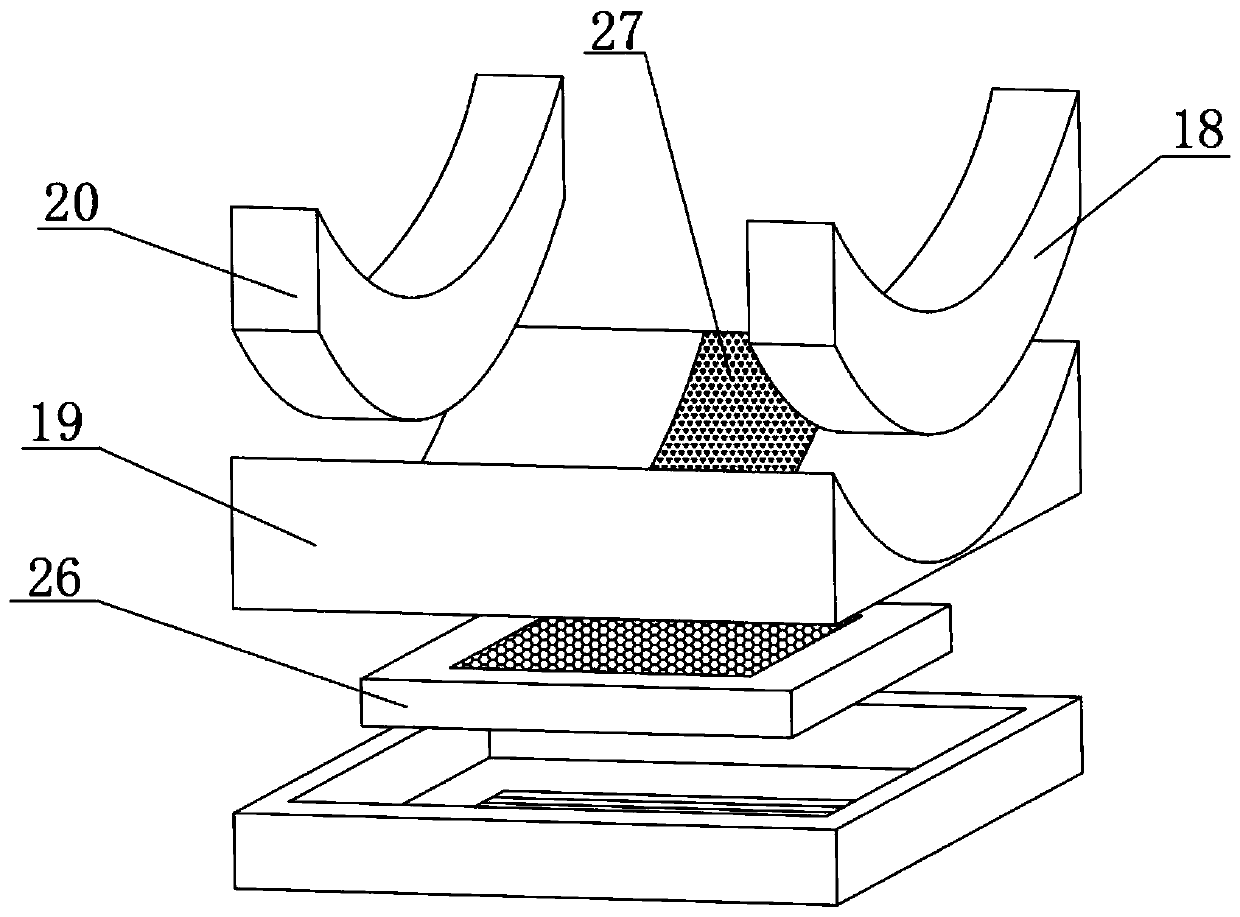

[0029] A pipe laying device for building construction, such as Figure 1-3 As shown, it includes a fixed machine platform 16, the top of the fixed machine platform 16 is connected with a horizontally arranged pipeline cabinet 8 by bolts, the middle of one side of the pipeline cabinet 8 is connected with a horizontally arranged power cabinet 7 by bolts, and one side of the fixed machine platform 16 One end of the platform is connected with a horizontally arranged pallet 1 22 by bolts, and the other end of the fixed machine 16 side is connected with a horizontally arranged pallet 2 17 by bolts, and the tops of the pallet 2 17 and the pallet 1 22 are provided with An arc-shaped groove, one side of the fixed machine platform 16 is located at one end of the supporting platform 2 17 and is connected with a horizontally arranged welding platform 19 by bolts, and one end of the top of the welding platform 19 is connected with a vertically arranged supporting bracket 1 20 by bolts, The...

Embodiment 2

[0033] A pipe laying device for building construction, such as Figure 1-4 As shown, the top of the pallet two 17 and the bottom of the fixed top plate two 15 are all pressed together with a vertically arranged rubber anti-skid bump 28 .

[0034] When the present embodiment is in use, in the second embodiment, the rubber anti-skid bumps installed vertically on the top of the platform two 17 and the bottom of the fixed top plate two 15 can effectively prevent the The welded pipes are unstable, resulting in welding failure, making the welding safer and more reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com