Connection structure between drainage tunnel and main line tunnel

A technology of drainage tunnels and main lines, applied in tunnels, drainage, safety devices, etc., can solve problems such as insufficient drainage capacity of drainage ditches and high water pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

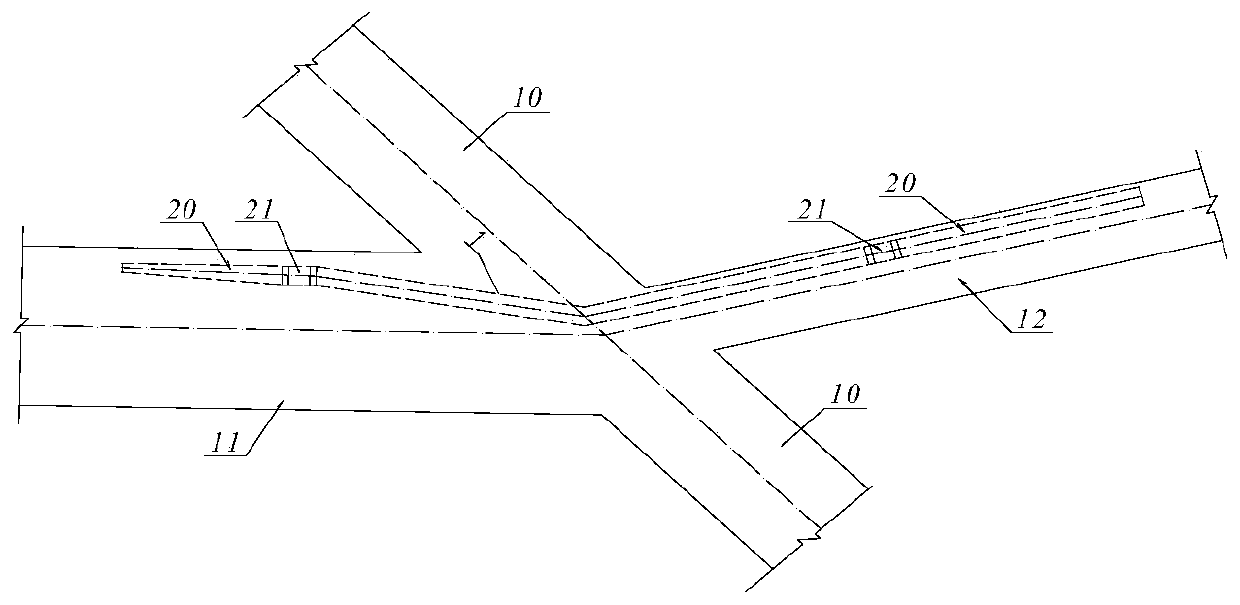

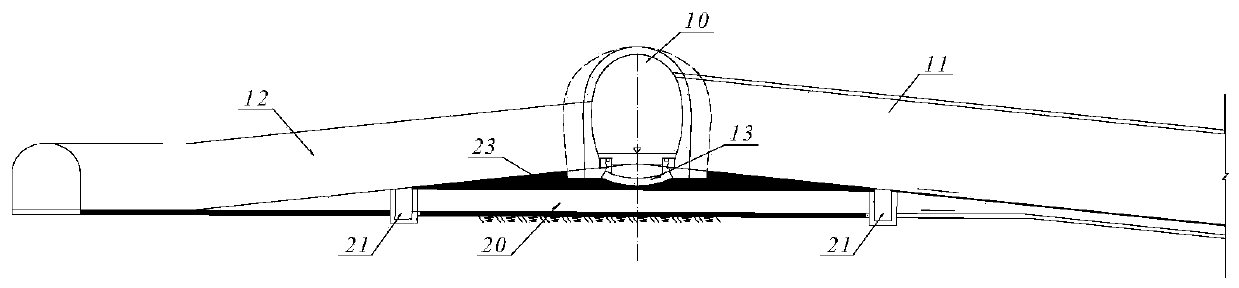

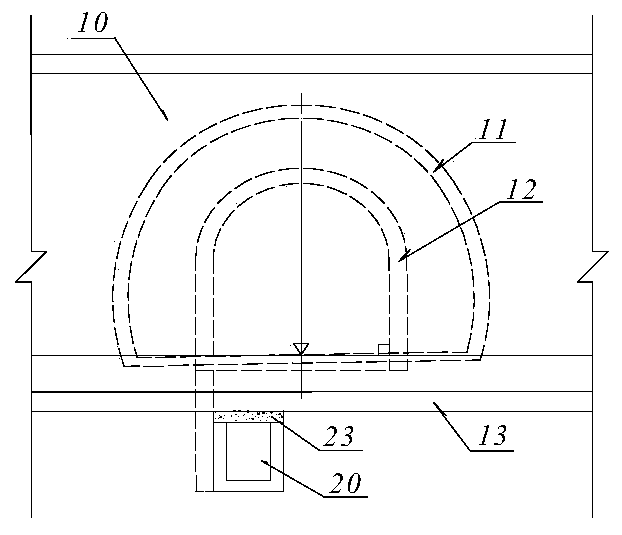

[0016] refer to figure 1 , figure 2 with image 3 , a connection structure between a drain tunnel and a mainline tunnel of the present invention, comprising a mainline tunnel 10, an existing horizontal tunnel 11 on one side thereof, a new drainage tunnel 12, a drainage ditch 20 and a water collection well 21. The other side of the main line tunnel 10 is provided with a newly built drainage tunnel 12, the newly built drainage tunnel 12, the existing horizontal hole 11 and the main line tunnel 10 form an intersection, and the lining structure of the main line tunnel 10 is drawn under the inverted arch 13. Groove excavation and construction of the drainage ditch 20, the two ends of the drainage ditch 20 respectively extend to the new drainage tunnel 12, the existing horizontal hole 11 and the water collection well 21 is set, and the concrete is set abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com