Polyester silk with relatively strong acid and alkali resistance and good moisture removal performance

A polyester yarn, acid and alkali resistance technology, applied in the field of polyester yarn, can solve the problems of poor moisture removal effect and effective anti-corrosion effect, and achieve good moisture absorption effect and good moisture removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

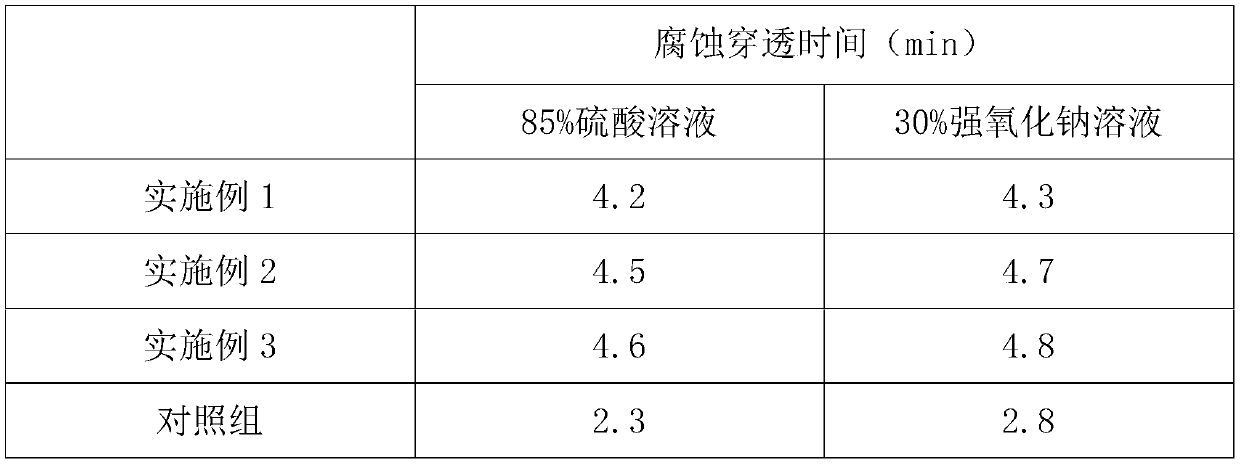

Examples

Embodiment 1

[0023] The manufacturing method of polyester yarn includes the following steps:

[0024] a. Material selection: use hygroscopic polyester fiber, polyurethane fiber, flame-retardant aramid, carbon fiber and glass fiber as raw materials;

[0025] b. One-time spinning: the hygroscopic polyester fiber, polyurethane fiber, flame-retardant aramid, carbon fiber and glass fiber are spun through a spinning machine;

[0026] c. Anti-acid and alkali treatment: soak the material obtained in step b in an anti-acid and alkali treatment solution. The composition of the anti-acid and alkali treatment solution is: polyvinyl chloride, polyurethane, acrylate, monoammonium phosphate, boric acid and water;

[0027] d. Drying treatment: take out step c after soaking, and dry it in the hot air drying room;

[0028] e. Secondary spinning: take the nylon slender rod coated with flame-retardant heat insulation material as the basic fixed rod, and wind several materials after step c on the nylon slender rod in tu...

Embodiment 2

[0036] a. Material selection: use hygroscopic polyester fiber, polyurethane fiber, flame-retardant aramid, carbon fiber and glass fiber as raw materials;

[0037] b. One-time spinning: the hygroscopic polyester fiber, polyurethane fiber, flame-retardant aramid, carbon fiber and glass fiber are spun through a spinning machine;

[0038] c. Anti-acid and alkali treatment: soak the material obtained in step b in an anti-acid and alkali treatment solution. The composition of the anti-acid and alkali treatment solution is: polyvinyl chloride, polyurethane, acrylate, monoammonium phosphate, boric acid and water;

[0039] d. Drying treatment: take out step c after soaking, and dry it in the hot air drying room;

[0040] e. Secondary spinning: take the nylon slender rod coated with flame-retardant heat insulation material as the basic fixed rod, and wind several materials after step c on the nylon slender rod in turn, and then use the spinning machine After spinning, take off the nylon slender...

Embodiment 3

[0048] a. Material selection: use hygroscopic polyester fiber, polyurethane fiber, flame-retardant aramid, carbon fiber and glass fiber as raw materials;

[0049] b. One-time spinning: the hygroscopic polyester fiber, polyurethane fiber, flame-retardant aramid, carbon fiber and glass fiber are spun through a spinning machine;

[0050] c. Anti-acid and alkali treatment: soak the material obtained in step b in an anti-acid and alkali treatment solution. The composition of the anti-acid and alkali treatment solution is: polyvinyl chloride, polyurethane, acrylate, monoammonium phosphate, boric acid and water;

[0051] d. Drying treatment: take out step c after soaking, and dry it in the hot air drying room;

[0052] e. Secondary spinning: take the nylon slender rod coated with flame-retardant heat insulation material as the basic fixed rod, and wind several materials after step c on the nylon slender rod in turn, and then use the spinning machine After spinning, take off the nylon slender...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com