Nano-silica composite graphene cooling liquid and preparation method thereof

A technology of composite graphene and silica, applied in chemical instruments and methods, materials for heat exchange, etc., can solve problems such as hindering graphene research and application, difficult to stably disperse, weak interaction force, etc., and achieve excellent stability. properties, excellent thermal conductivity, and the effect of hindering agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

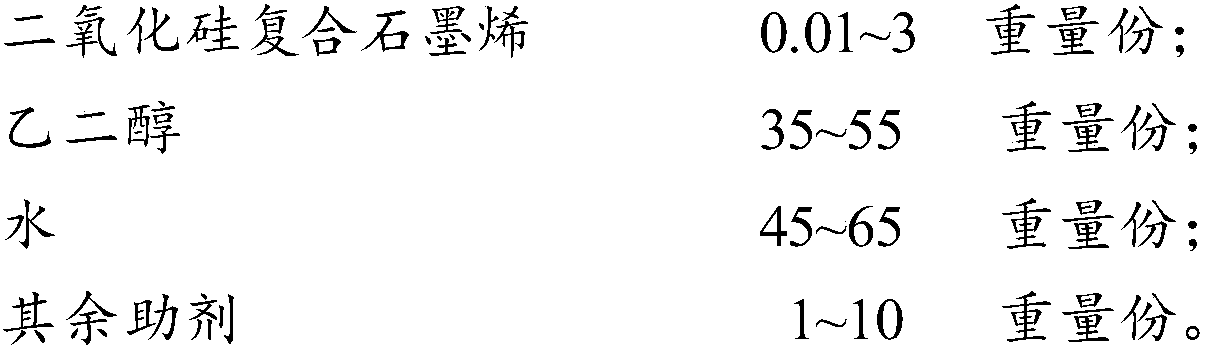

[0076] The present invention also provides a method for preparing a silicon dioxide composite graphene cooling liquid as described in any one of the above technical solutions, characterized in that, comprising the following steps:

[0077] 1) After continuous mixing of silicon dioxide composite graphene, water, ethylene glycol and other additives, a silicon dioxide composite graphene cooling liquid is obtained.

[0078] The present invention is to the selection and composition of raw materials in the preparation method of described silicon dioxide composite graphene cooling liquid, and corresponding optimization principle, and the selection and composition of corresponding raw materials in the aforementioned silicon dioxide composite graphene cooling liquid, and Corresponding optimization principles can all be corresponding, and details will not be repeated here.

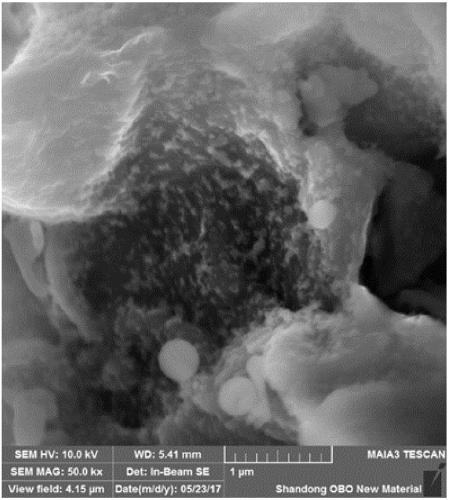

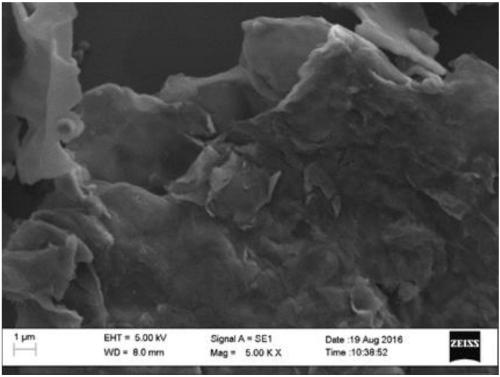

[0079] In principle, the present invention has no special restrictions on the source and preparation method of th...

Embodiment 1

[0125] 1. Dissolve graphene oxide in an aqueous solution, ultrasonically and stir at room temperature to obtain 25 g of graphene oxide dispersion. Among them, the mass fraction of the graphene oxide dispersion solution is 8‰, the ultrasonic time is 120min, the ultrasonic frequency is 40KHz, and the stirring speed is 250r / min;

[0126] 2. Add 40 mg sodium hydroxide and 1.0 g cetyltrimethylammonium bromide to the graphene oxide dispersion obtained in step 1, continue stirring for 180 min, and rotate at a speed of 300 r / min to obtain a mixed solution A;

[0127] 3. Add 0.8mLTEOS tetraethyl orthosilicate to the mixed solution A obtained in step 2, and continue to stir for 120min at a speed of 300r / min to obtain a mixed solution B;

[0128] 4. Reflux the mixed solution B obtained in step 3 at 120° C. for 18 hours, and magnetically stir at 300 r / min.

[0129] 5. Suction filter the mixed solution C obtained in step 4 to obtain a filter cake, and dry it in an oven for 60 minutes at a...

Embodiment 2

[0145] Mix 60L ethylene glycol with 40L high-purity water, stir evenly, add 2.5kg tolutriazole, 1kg isooctanoic acid, 1.5kg tolyltriazole, 1kg heptanoic acid, stir ultrasonically for 30 minutes, then add thermal conductivity additive silica Composite graphene 0.1kg, ultrasonically stirred for 1h, after the heat conduction additive was uniformly dispersed, added 1kg of sodium benzoate, 0.5kg of borax, 0.5kg of dimethyl silicone oil, and stirred for 1h to obtain nano-silica composite graphene cooling liquid.

[0146] The thermal conductivity of the nano-silica composite graphene cooling liquid prepared in Example 2 of the present invention was tested.

[0147] Among them, the freezing point is <-45°C, and the specific thermal conductivity is shown in Table 1. Table 1 is a comparison of the thermal conductivity of the nano-silica composite graphene cooling liquid prepared in the embodiment of the present invention and the common cooling liquid of the same grade.

[0148] Corrosi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com