Polyether type polyurethane-graphene oxide foam as well as preparation method and application thereof

A technology of polyether polyurethane and graphene foam, applied in chemical instruments and methods, adsorption of water/sewage treatment, water pollutants, etc., can solve problems such as damage to cell integrity, oxidative stress damage, and cell membrane damage, and achieve Accelerate the efficiency of interspecies electron transfer, good hydrophilicity, and accelerate the effect of degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

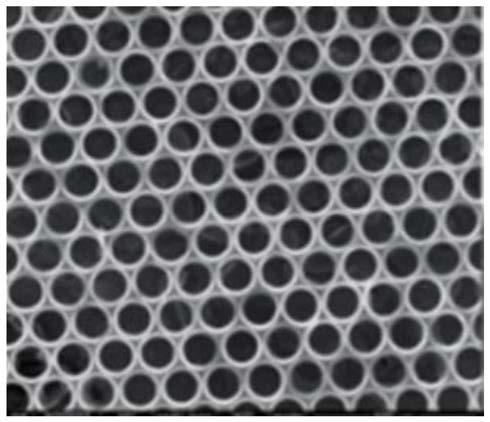

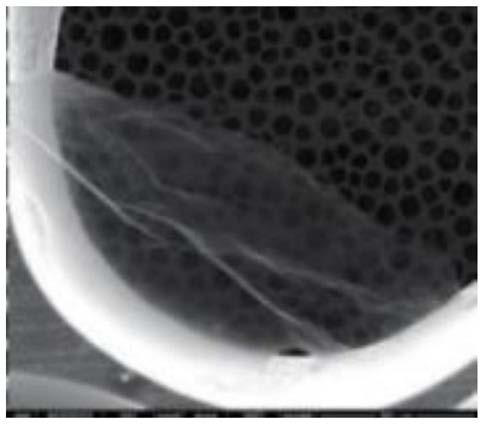

Image

Examples

Embodiment 1

[0034] 1) Weigh 5 mL of black material pure diphenylmethane diisocyanate (pure MDI), 10 mL of white material (polyurethane combined polyether: 200 kg 99.5% polyether polyol, 200 kg 99% silicone oil, catalyst and 200 kg chain extender); Mix the black material and the white material within 30s, stir with a glass rod at a speed of 100rpm until the liquid turns white, start to foam automatically for 5 minutes, until the foaming temperature drops to room temperature, the foaming is completed, divide into 2cm× 2cm×2cm square blocks, ultrasonically cleaned with 75% ethanol for 15 minutes, and dried in a constant temperature oven at 80°C for 15 minutes to obtain polyether polyurethane-graphene oxide foam.

[0035] 2) Accurately weigh 300 mg of multilayer graphene oxide solids with an analytical balance and place them in 1000 ml of ultrapure water for ultrasonic dispersion. The ultrasonic power is 450 W, and the speed of the stirring rod is set to 100 rpm. Stir once in half an hour, an...

Embodiment 2

[0038] 1) Weigh 5 mL of black material pure diphenylmethane diisocyanate (pure MDI), 10 mL of white material (polyurethane combined polyether: 200 kg 99.5% polyether polyol, 200 kg 99% silicone oil, catalyst and 200 kg chain extender); Mix the black material and the white material within 60s, stir with a glass rod at a speed of 80rpm until the liquid turns white, start to foam automatically for 3 minutes, until the foaming temperature drops to normal temperature, the foaming is completed, divide into 2cm× 2cm×2cm square blocks, ultrasonically cleaned with 75% ethanol for 15 minutes, and dried in a constant temperature oven at 80°C for 15 minutes to obtain polyether polyurethane-graphene oxide foam.

[0039] 2) Accurately weigh 300 mg of multilayer graphene oxide solids with an analytical balance and place them in 1000 ml of ultrapure water for ultrasonic dispersion. The ultrasonic power is 300 W, and the speed of the stirring rod is set to 100 rpm. Stir once in half an hour, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compression modulus | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com