Production line for ship support accessories

A production line and production line technology, which is applied to computer parts, cooperative devices, ships, etc., can solve the problems of production lines without ship support accessories, and achieve the effect of convenient production plan adjustment and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

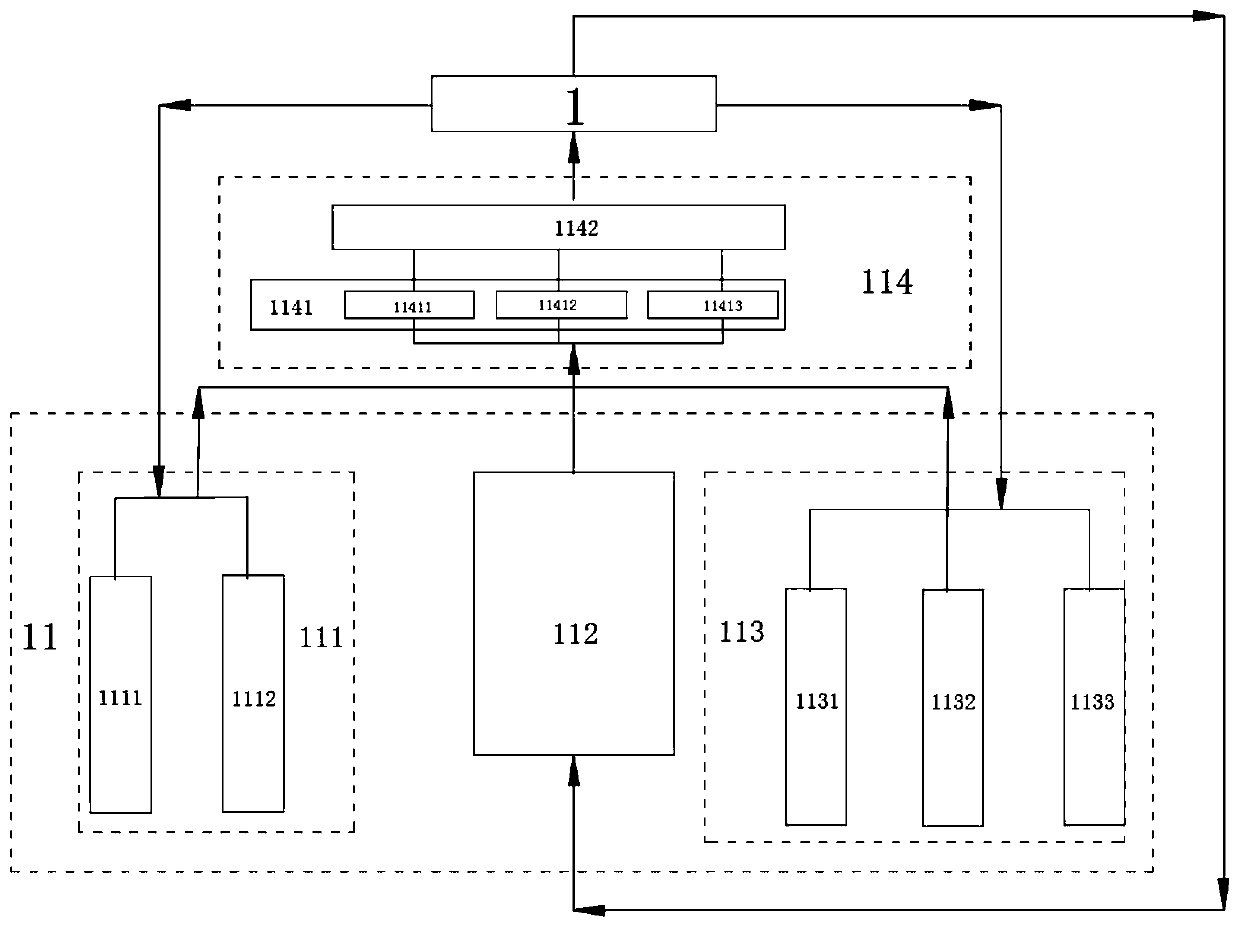

[0036] The cut-to-length material management module 111 includes a cut-to-length material storage 1111 and a cut-to-length material output 1112 .

[0037] Storage of cut-to-length materials 1111 includes the following steps:

[0038] (1) Inspection of the cut-to-size material is carried out after the arrival of the cut-to-size material, and the warehouse-in operation can be carried out after the cut-to-size material is qualified;

[0039] (2) The warehouse clerk fills in the batch information of the cut-to-size material, prints the UID label, and pastes it on the cut-to-size material bag, and sets the storage location for the cut-to-size material in the control system 1;

[0040] (3) Scan the fixed-size material label and the storage location label through the PDA, and the control system 1 judges the correctness of the corresponding relationship. If it is not correct, continue to scan and reposition until it is correct. After the judgment is correct, the inventory will automat...

Embodiment 2

[0047] The quality management module 112 realizes forward and backward traceability from products to cut-to-size materials through quality management and traceability systems.

Embodiment 3

[0049] The production management module 113 includes label management 1131, work order management 1132, and statistical analysis 1133; the label management 1131 is the management of product serial numbers, and the work order management 1132 includes successively making work orders, starting work orders, planning and scheduling, Production material preparation, process reporting, and production payment to the warehouse; the statistical analysis 1133 includes the following steps: the workshop management personnel understand the production progress of each work order in real time through the work order management, and generate a real-time report of the work order progress by recording the station information , for the workshop managers to check and make corresponding adjustments.

[0050] Through label management, work order management, and statistical analysis, production management realizes the full tracking of the production line of ship bracket accessories, and the coordinatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com