A ceiling laser welding wire body trial production equipment

A technology of laser welding wire and ceiling, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of long trial production cycle, increased trial production cost, waste, etc., to meet the requirements of multi-process trial production, reduce trial production cost, and low manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

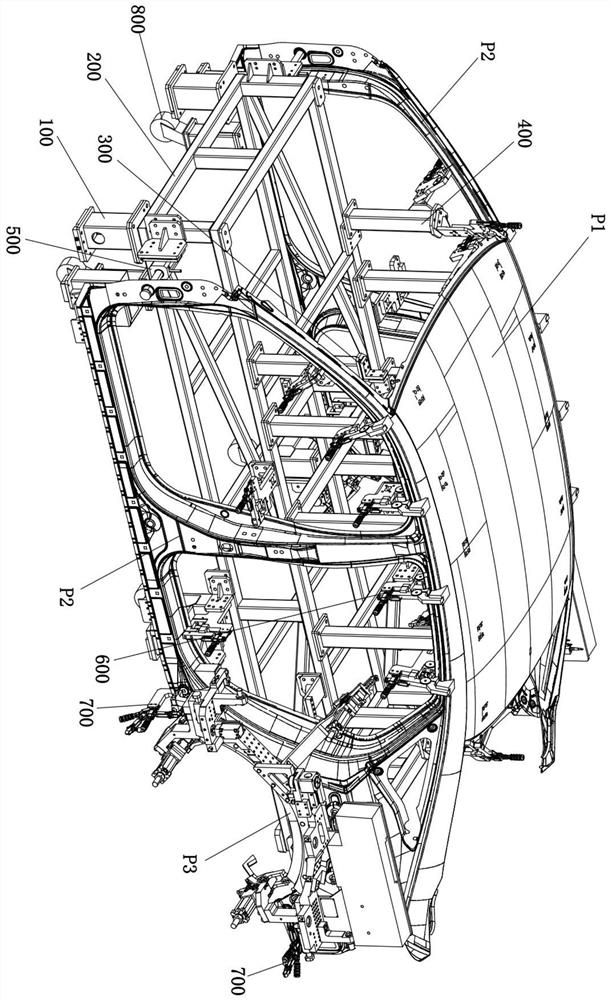

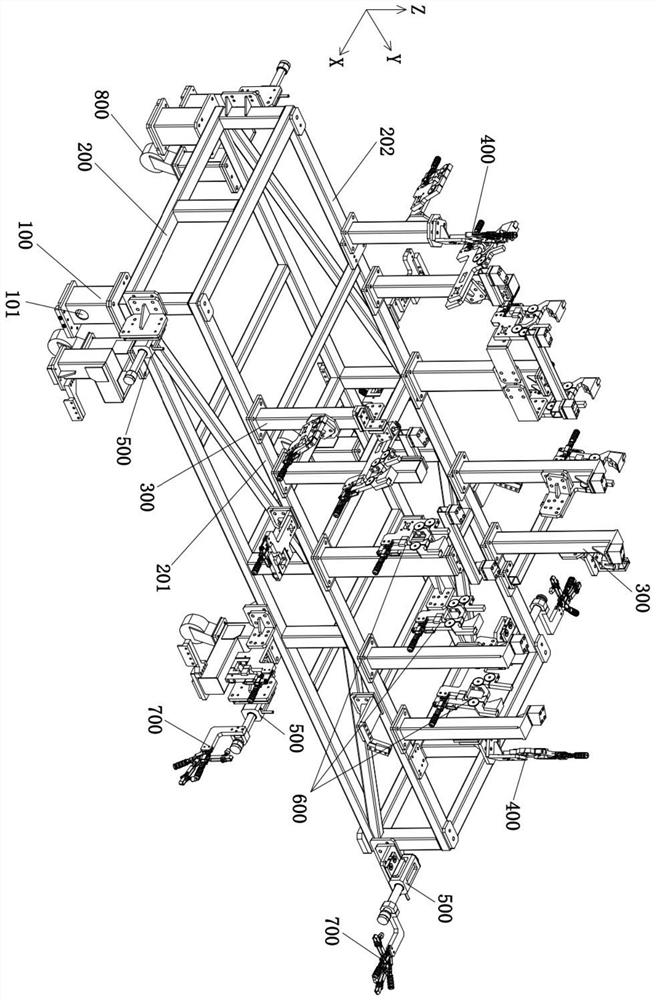

[0032] like Figure 1-3 As shown, the ceiling laser welding wire body trial production equipment in this embodiment includes: bases 100 (preferably 4), which can cooperate with the conveying mechanism to accurately transport the whole trial production equipment to the ceiling laser welding station, Working positions such as welding seam grinding station and wheel cover hemming station; and the base 100 is provided with a positioning hole 101, so that after the trial equipment is transported to the corresponding station, the positioning hole 101 is connected with the The connection of positioning structures such as pins accurately locates the trial-manufacturing equipment to ensure that it is in an accurate trial-manufacturing position;

[0033] A frame 200, which is connected to the base 100, has a first side 201 and a second side 202 arranged in parallel in the Y direction;

[0034] The first roof positioning unit 300, which is connected to the first side 201 and / or the seco...

Embodiment 2

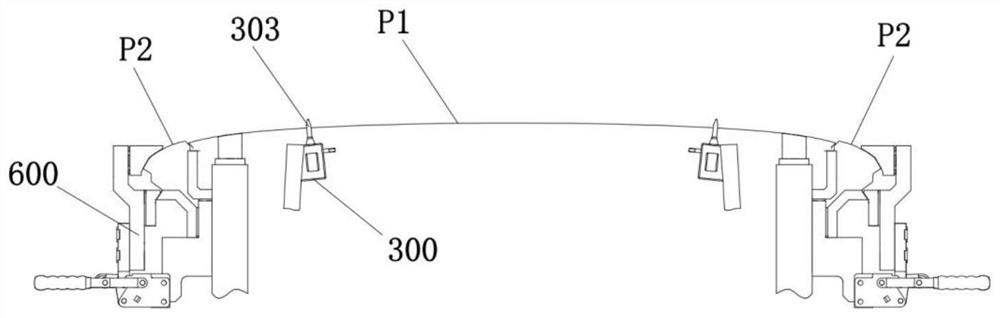

[0040] The only difference between this embodiment and Embodiment 1 is that, as figure 1 , shown in 4, the first ceiling positioning unit 300 includes: a first connecting column 301, which is connected to the frame 200; a ceiling positioning block 302 (preferably a nylon profiling block), which is connected to the first connecting column 301 and a positioning pin 303, which is connected to the ceiling positioning block 302 and performs Z-direction positioning on the ceiling outer panel P1 after passing through the ceiling outer panel P1.

[0041] The second ceiling positioning unit 400 includes: telescopic pins (such as manual telescopic pins, etc.), whose positions correspond to the positioning holes on the ceiling outer panel P1, and the telescopic pins can extend into / pass through the positioning holes on the ceiling outer panel P1. holes to realize XY positioning of the ceiling outer panel P1.

[0042] like Figures 5a-5b As shown, the side circumference positioning unit 5...

Embodiment 3

[0045] The only difference between this embodiment and embodiment 2 is that, as Figures 6a-6b As shown, the side wall clamping unit 600 in this embodiment further includes: a side wall supporting block 606, which is connected to the first clamping block 602, and is used to support the weight of the side wall outer panel P2; and a side wall The fixing block 605 (preferably a nylon profiling block), which is connected to the second clamping block 603, is used to be attached to the appearance surface of the side wall outer panel P2, so that the side wall outer panel P2 can be fixed in the X direction. fixed.

[0046] When the side wall outer panel P2 is located at the first clamping block 607 and the second clamping block 608, the first handle 604 is manually turned, and the second side wall positioning block 603 is rotated relative to the first side wall positioning block 602, so that The first clamping block 607 and the second clamping block 608 approach and clamp and fix the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com