Coffee brewing mechanism and method for making coffee by using mechanism

A coffee and guide post technology, applied in applications, home utensils, kitchen utensils, etc., can solve the problems of unstable coffee concentration, take a long time, take a long time, etc., to improve coffee taste, shorten production time, and improve stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

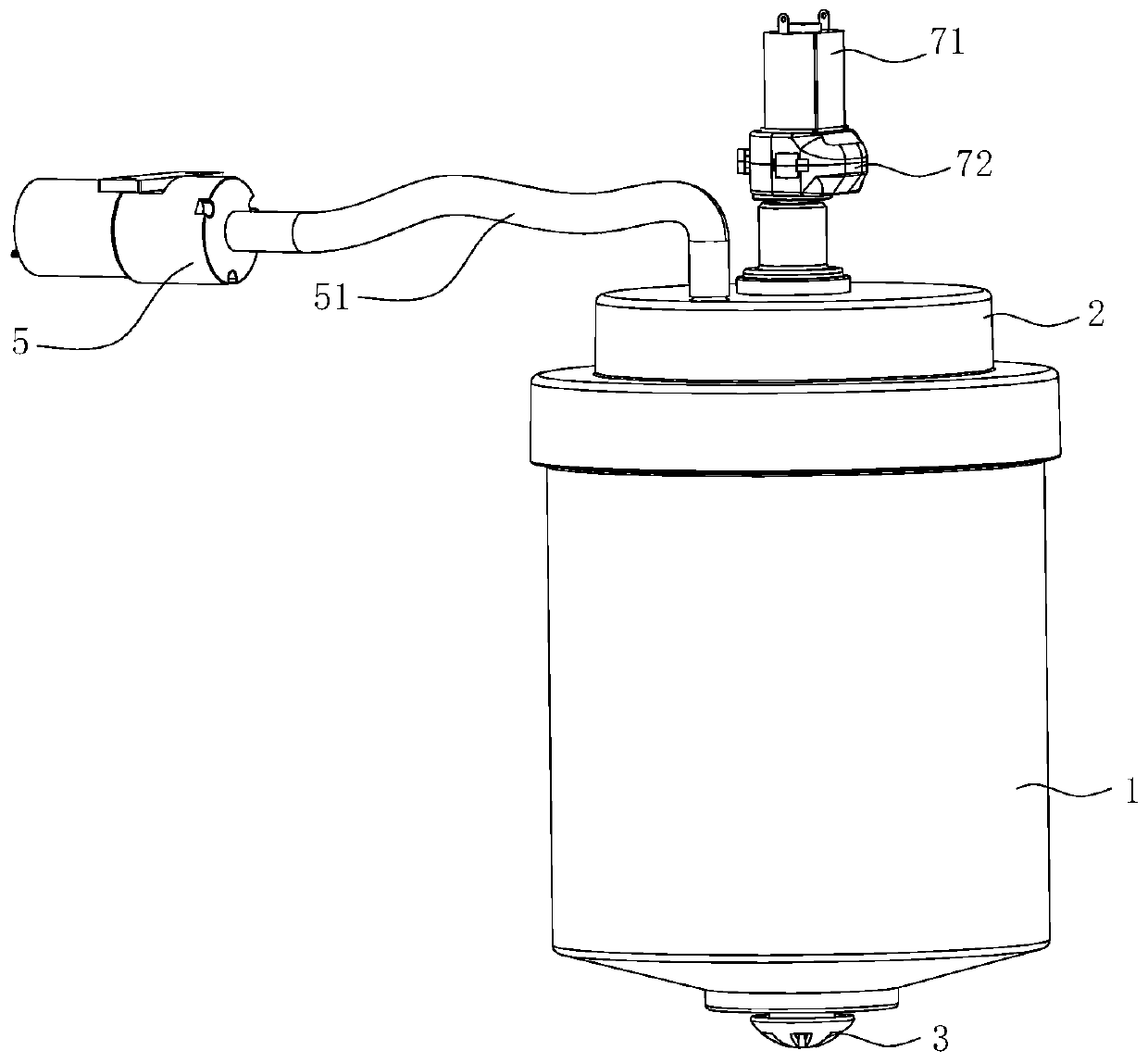

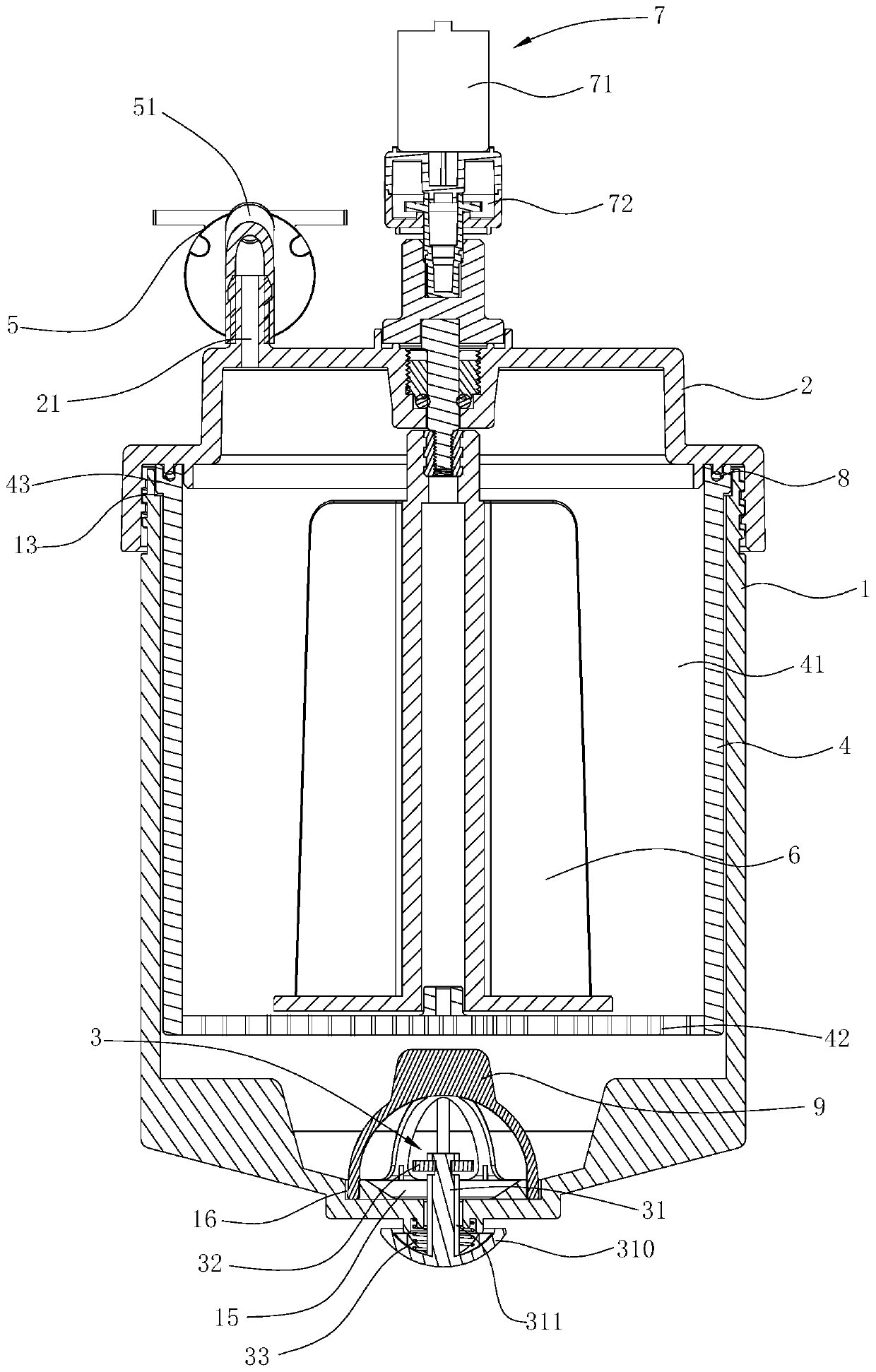

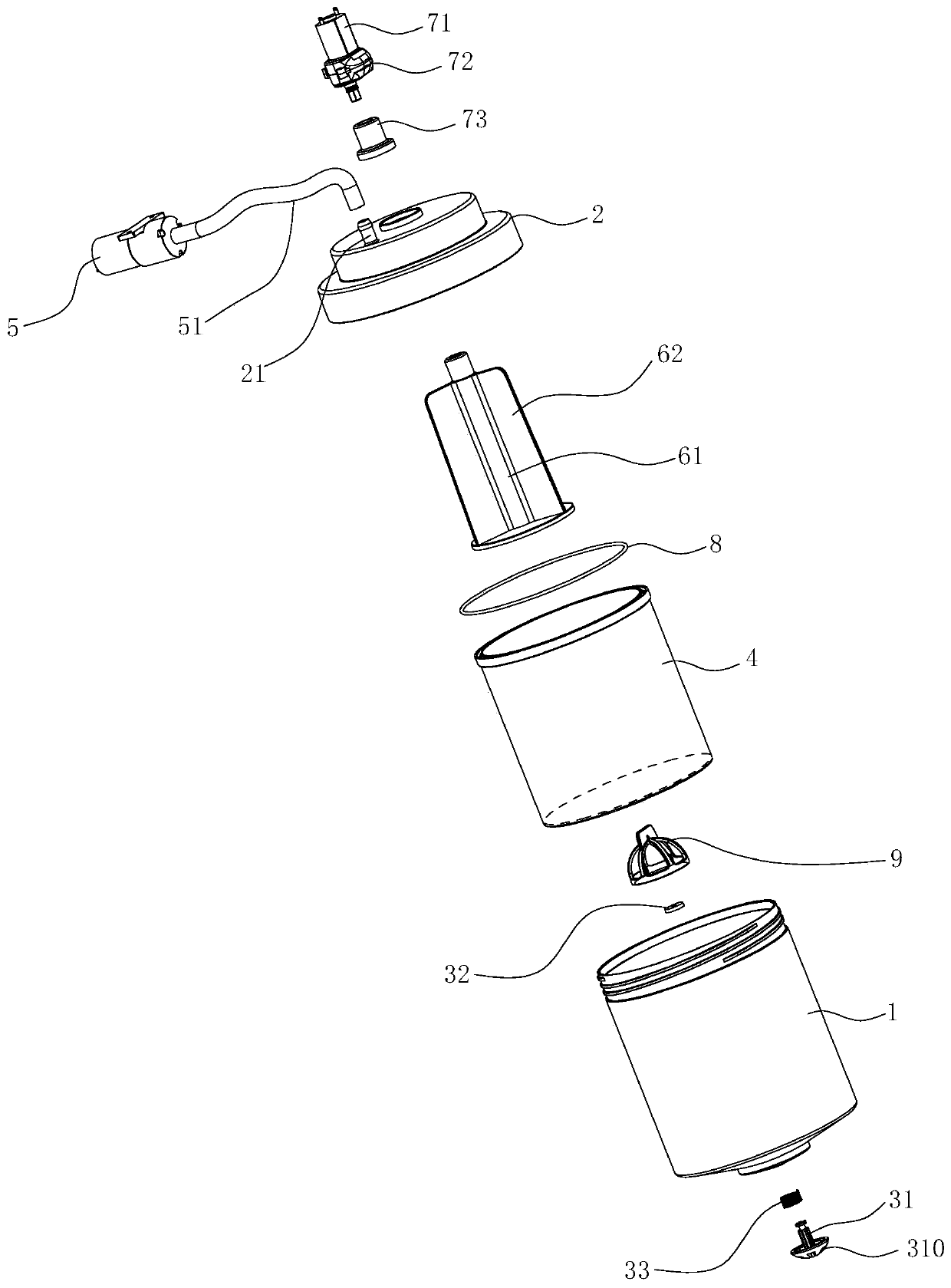

Image

Examples

Embodiment 2

[0050] The difference between this embodiment and Embodiment 1 is:

[0051] like Figure 7 As mentioned above, the assembly relationship between the brewing box and the inner box in this embodiment is different from that in Embodiment 1. In this embodiment, the height of the inner cavity of the brewing box 1' is relatively small, while the height of the inner cavity of the inner box 4' is not affected. During assembly, only the bottom of the inner box 4' is inserted into the brewing box 1' and is connected to the brewing box 1'. Box 1' threaded connection. The end cap 2' is placed on the top of the inner box 4' and is screwed with the inner box 4'.

[0052] Figure 7 , 8 As shown, the structure of the switch assembly 3' in this embodiment is different from that of the first embodiment. In this embodiment, the bottom of the guide post 31 ′ is not provided with a bowl-shaped base, but is provided with an independent bottom bracket 34 . The bottom bracket 34 has a cylindrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com