Conductive film of fiber composite material with interface interlocking structure and preparation method thereof

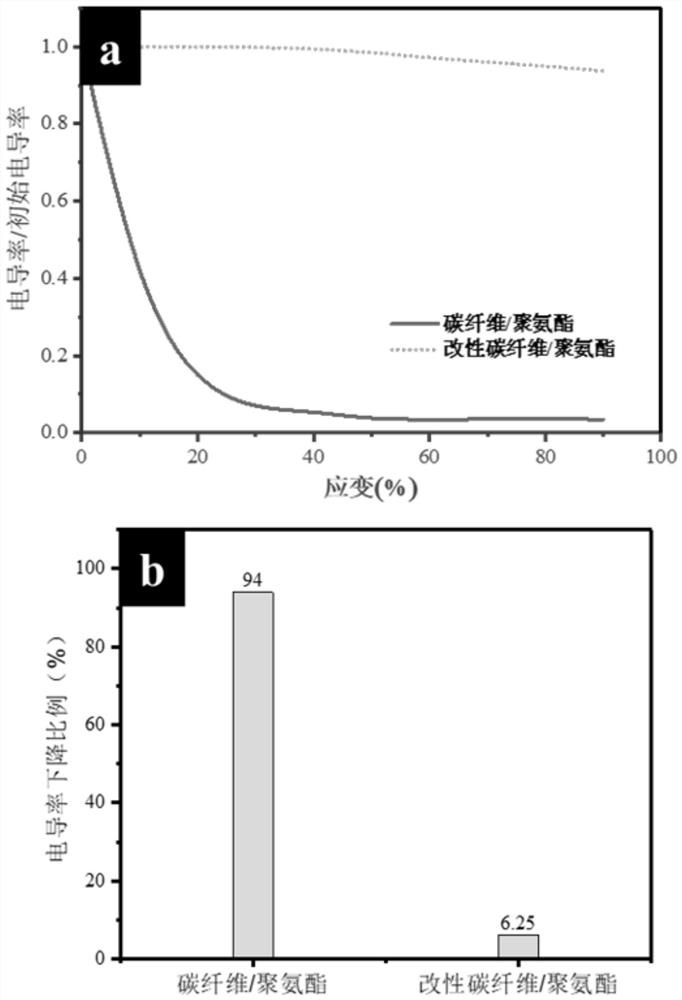

A fiber composite material, conductive film technology, applied to conductive layers on insulating carriers, equipment for manufacturing conductive/semiconducting layers, cable/conductor manufacturing, etc., can solve complex processing processes, poor interface performance, and ineffectiveness to limit the relative slippage of conductive fillers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A method for preparing a fiber composite conductive film with an interface interlocking structure, comprising the following steps in sequence:

[0059] (1) Encapsulated polydopamine:

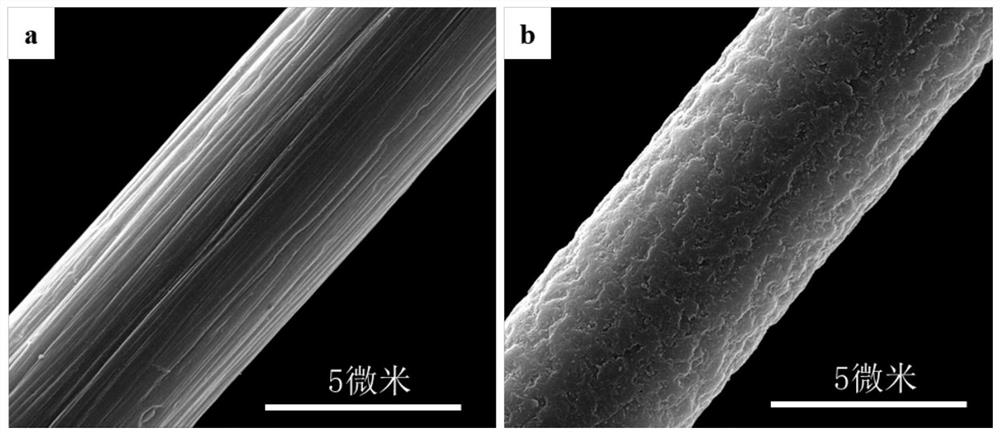

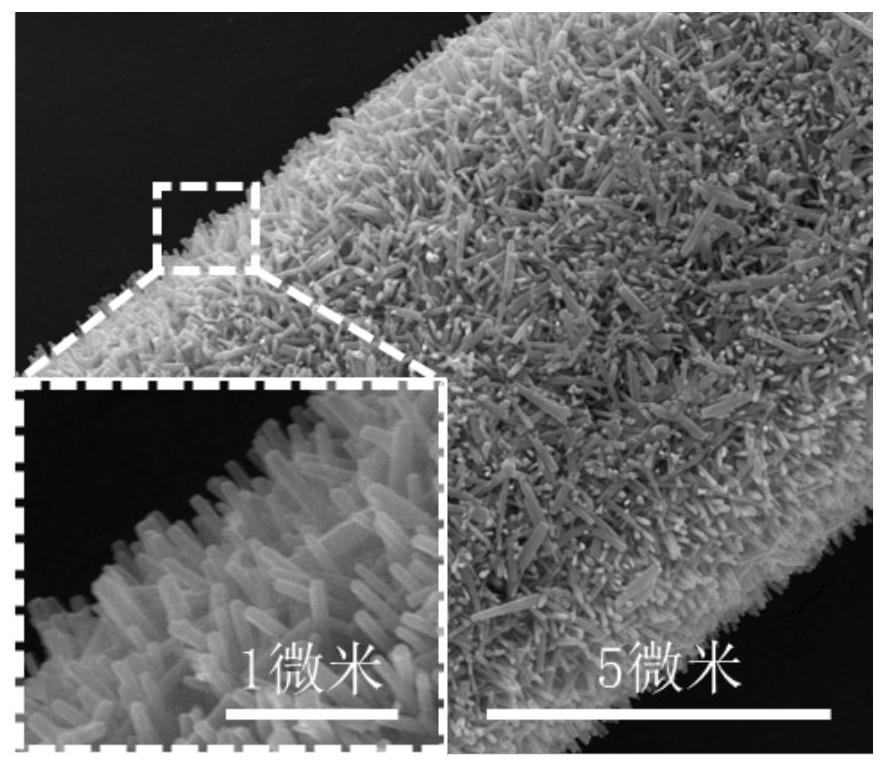

[0060] Chopped carbon fiber is selected (SYT49S 12K short-cut carbon fiber produced by Zhongfu Shenying Carbon Fiber Co., Ltd.). The chopped carbon fiber is placed in acetone and stirred for 2 hours to remove surface impurities. After 2 hours of ultrasonic cleaning with deionized water drying spare;

[0061] Dissolve dopamine hydrochloride in deionized water to prepare a dopamine hydrochloride aqueous solution with a concentration of 3g / L, and adjust the pH value of the dopamine hydrochloride aqueous solution to 8.5 through a Tris-hydrochloric acid buffer solution; then use an ultrasonic water bath to disperse the chopped carbon fibers to the adjusted Add the dopamine hydrochloride aqueous solution after the pH value, and then mechanically stir at 30°C for 8 hours. After the stirring tim...

Embodiment 2

[0074] A method for preparing a fiber composite conductive film with an interface interlocking structure, comprising the following steps in sequence:

[0075] (1) Encapsulated polydopamine:

[0076] Chopped carbon fiber is selected (SYT49S 12K short-cut carbon fiber produced by Zhongfu Shenying Carbon Fiber Co., Ltd.). The chopped carbon fiber is placed in acetone and stirred for 2 hours to remove surface impurities. After 2 hours of ultrasonic cleaning with deionized water drying spare;

[0077] Dissolve dopamine hydrochloride in deionized water to prepare a dopamine hydrochloride aqueous solution with a concentration of 10g / L, and adjust the pH value of the dopamine hydrochloride aqueous solution to 9 through Tris-hydrochloric acid buffer solution; then use an ultrasonic water bath to disperse the chopped carbon fibers to the adjusted Add the dopamine hydrochloride aqueous solution after the pH value, and then mechanically stir at 45°C for 12 hours. After the stirring time ...

Embodiment 3

[0088] A method for preparing a fiber composite conductive film with an interface interlocking structure, comprising the following steps in sequence:

[0089] (1) Encapsulated polydopamine:

[0090] Chopped carbon fiber is selected (SYT49S 12K short-cut carbon fiber produced by Zhongfu Shenying Carbon Fiber Co., Ltd.). The chopped carbon fiber is placed in acetone and stirred for 2 hours to remove surface impurities. After 2 hours of ultrasonic cleaning with deionized water drying spare;

[0091] Dissolve dopamine hydrochloride in deionized water to prepare a dopamine hydrochloride aqueous solution with a concentration of 2 g / L, and adjust the pH value of the dopamine hydrochloride aqueous solution to 8 through Tris-hydrochloric acid buffer solution; then use an ultrasonic water bath to disperse the chopped carbon fibers to the adjusted In the dopamine hydrochloride aqueous solution after the pH value, mechanically stir at 30°C for 5h. After the stirring time is up, wash with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com