Nuclear magnetism and rock electricity experiment process of mixed rock

A diamictite and nuclear magnetic technology, applied in the field of nuclear magnetic and rock electric experiment technology, can solve the problems of tight core displacement difficulties and low signal-to-noise ratio of experimental results, so as to improve the effect of washing oil and salt, improve the accuracy of experiments, and ensure the effect of clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

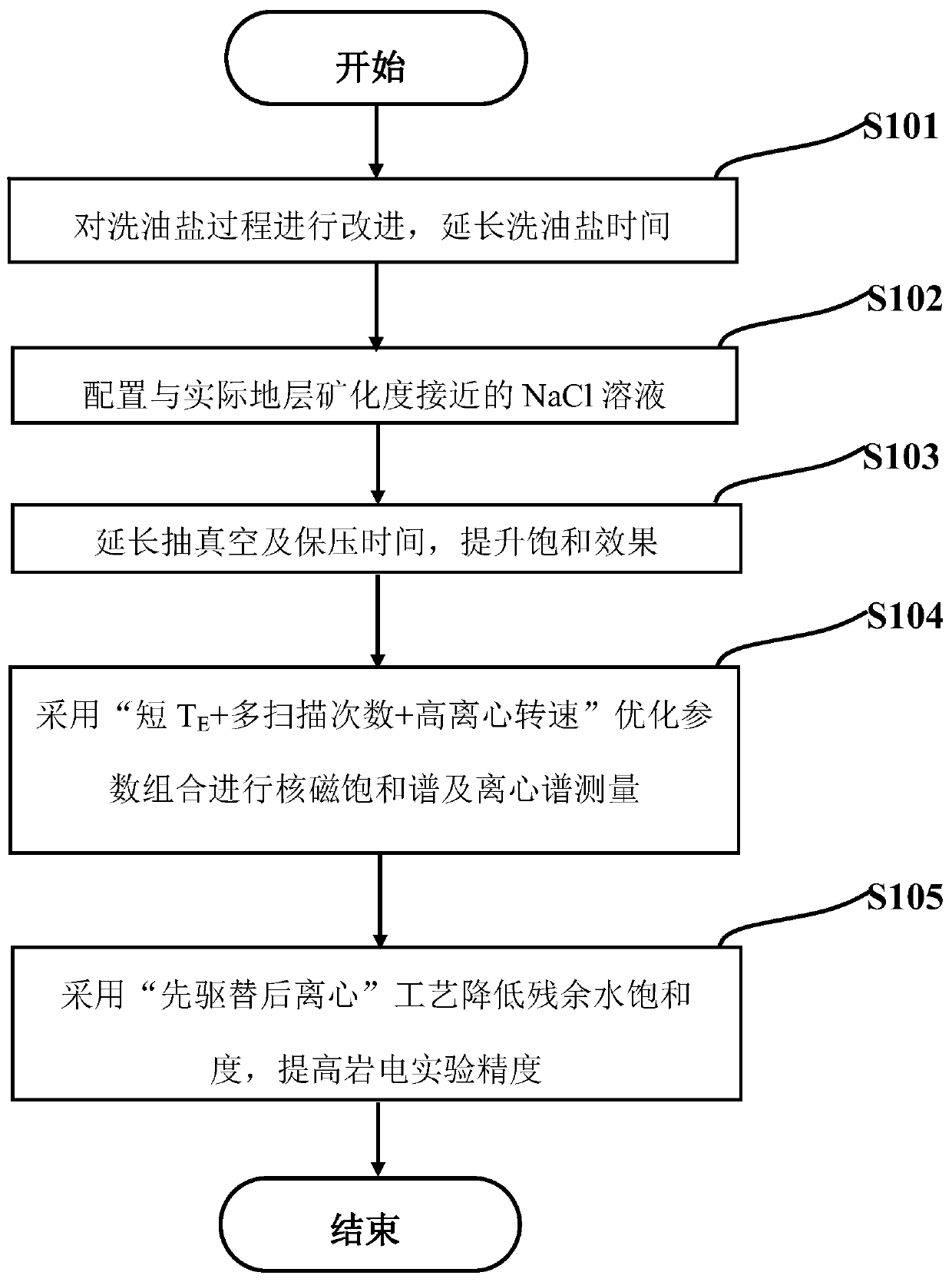

Method used

Image

Examples

Embodiment 1

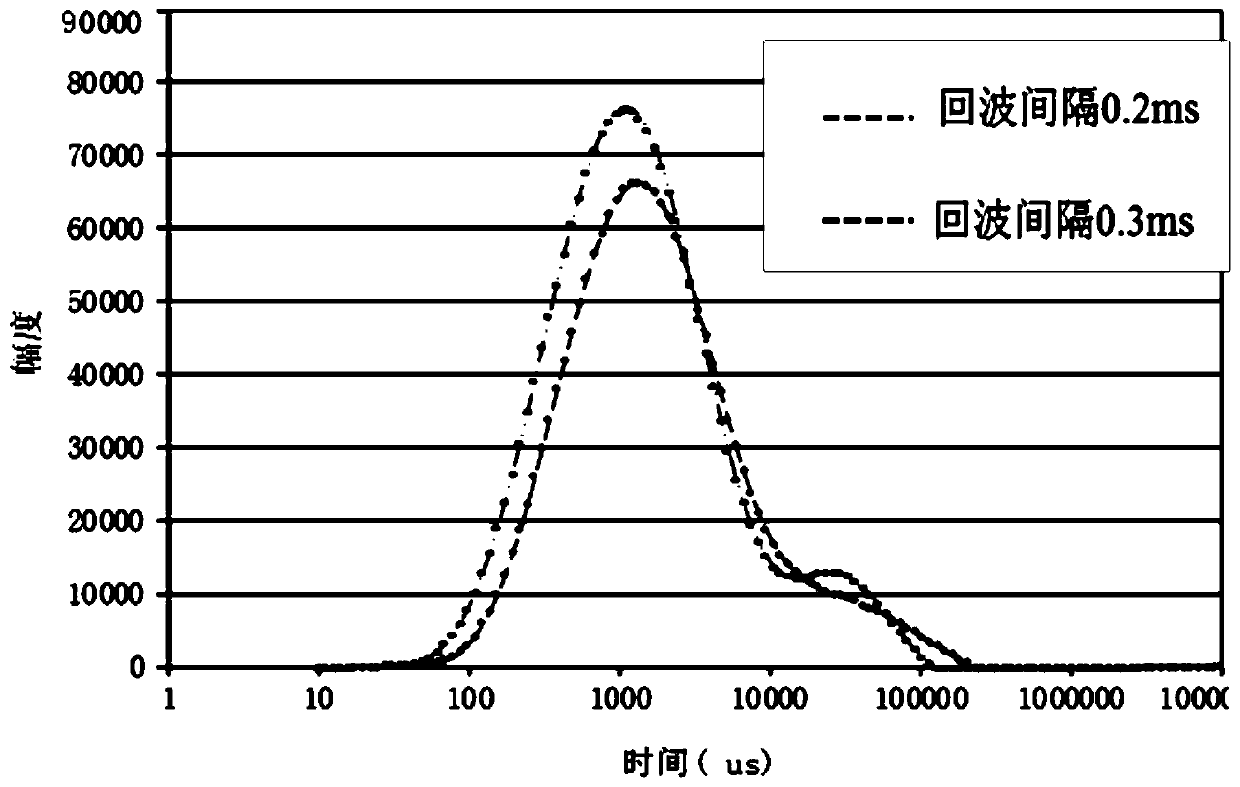

[0044] The present invention takes the actual petrophysical experiment of a typical diamictite coring well in an oil field as an example, and takes No. 2 sample of Well X for the experiment, and the experiment process includes:

[0045] Step 1, place the diamictite rock sample in an airtight container, and vacuumize to a vacuum degree of 6.7×10 -4 Pa; the holding time under vacuum is 6h; then the rock sample is placed in carbon tetrachloride and then placed in benzyl alcohol solvent for pressure cleaning, the pressure is 1MPa, and the cleaning time is 72h;

[0046] Step 2, after the cleaning is completed, put the rock sample in a closed container and vacuumize to a vacuum degree of 6.7×10 - 4 Pa;, the holding time under vacuum is 3h;

[0047] Step 3, configure the NaCl saturated solution that is consistent with the actual formation. This example is a NaCl saturated solution with a high salinity of 260,000 ppm. Place the rock sample treated in step 2 in the NaCl saturated sol...

Embodiment 2

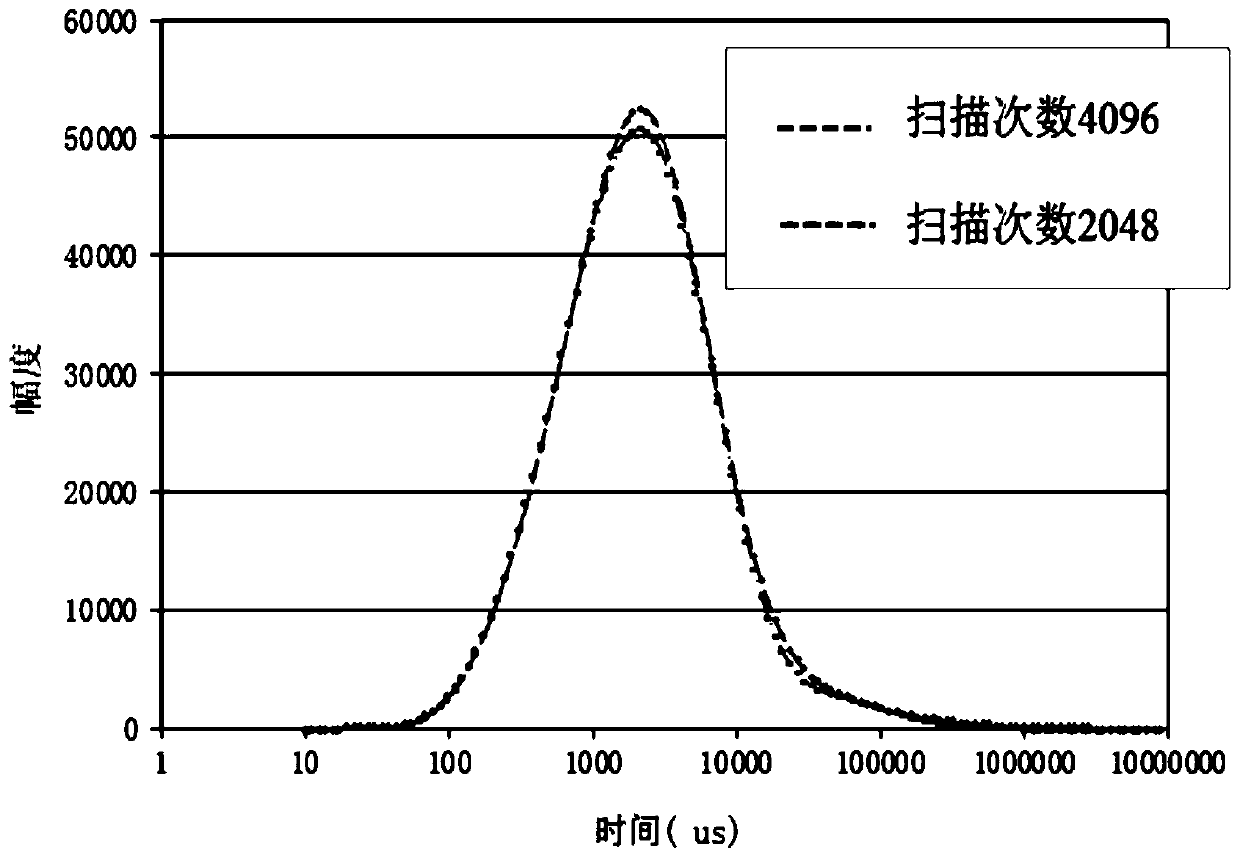

[0053] The present invention takes the actual petrophysical experiment of a typical diamictite coring well in an oil field as an example, sample No. 8 of Well Y, and the experimental process includes:

[0054] Step 1, place the diamictite rock sample in an airtight container, and vacuumize to a vacuum degree of 6.7×10 -2 Pa; the holding time under vacuum is 4h; then the rock sample is placed in carbon tetrachloride and then placed in benzyl alcohol solvent for pressure cleaning, the pressure is 0.5MPa, and the cleaning time is 36h;

[0055] Step 2, after the cleaning is completed, put the rock sample in a closed container and vacuumize to a vacuum degree of 6.7×10 - 2 Pa, the holding time under vacuum is 2h;

[0056] Step 3, configure the NaCl saturated solution that is consistent with the actual formation. This example is a NaCl saturated solution with a high salinity of 260,000 ppm. Place the rock sample treated in step 2 in the NaCl saturated solution for immersion satura...

Embodiment 3

[0062] The present invention takes the actual petrophysical experiment of a typical diamictite coring well in an oilfield as an example, and the experimental process includes:

[0063] Step 1, place the diamictite rock sample in an airtight container, and vacuumize to a vacuum degree of 6.7×10 -3 Pa; the holding time under vacuum is 7h; then the rock sample is firstly placed in carbon tetrachloride and then placed in benzyl alcohol solvent for pressure cleaning, the pressure is 1.5MPa, and the cleaning time is 96h;

[0064] Step 2, after the cleaning is completed, put the rock sample in a closed container and vacuumize to a vacuum degree of 6.7×10 - 3 Pa, the holding time under vacuum is 5h;

[0065] Step 3, configure the NaCl saturated solution that is consistent with the actual formation. In this example, it is a NaCl saturated solution with a high salinity of 200,000 ppm. Place the rock sample treated in step 2 in the NaCl saturated solution for immersion saturation. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com