Intelligent positioning and line drawing device for vehicle loading wheel position in bridge static load test

A static load test and intelligent positioning technology, applied in the direction of measuring devices, electrical devices, optical devices, etc., can solve the problems that the value cannot be traced back to the source, the amount of paint spraying is difficult to control, difficult to find and correct, etc., to achieve convenience Wheel position data and line drawing data, simplified preparation work, uniform thickness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

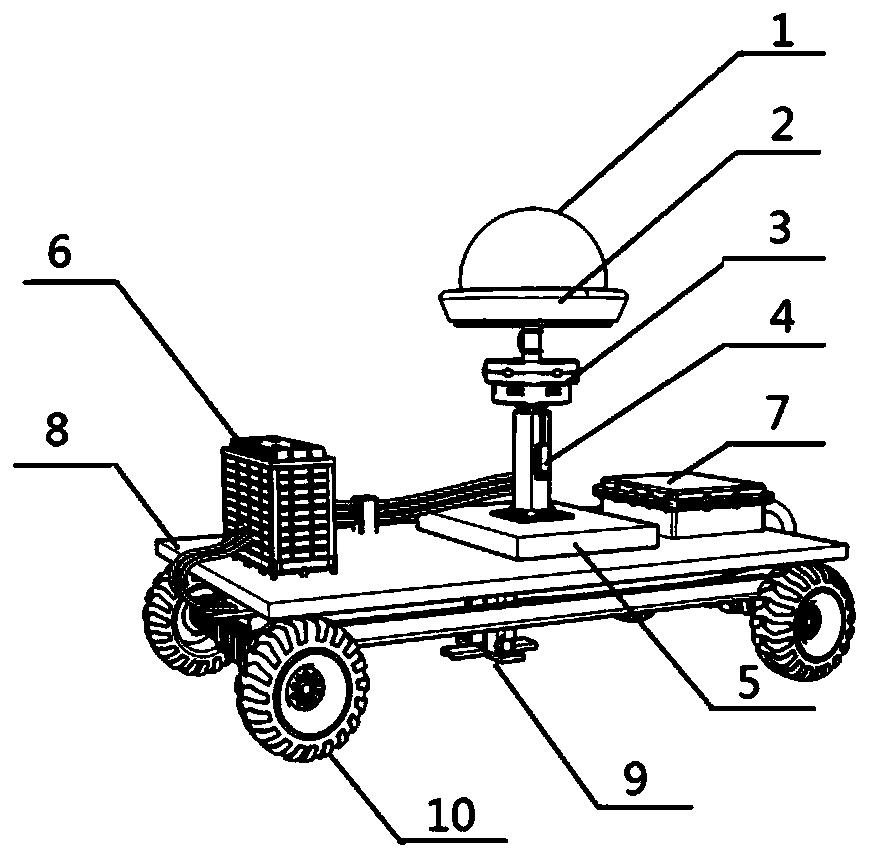

[0030] In the bridge static load test, the bridge is divided into orthogonal bridges and skew bridges. According to the loading conditions, the orthogonal bridges and skew bridges are divided into normal load conditions and eccentric load conditions. The bridges are under normal load conditions. The bridge deck is divided into even-numbered lanes and odd-numbered lanes; using the intelligent positioning and line drawing device for vehicle loading wheel positions in the bridge static load experiment, the static load vehicle wheel position positioning and line drawing of a three-span almost bridge are carried out as follows:

[0031] Place prisms on the curb stones on both sides of the expansion joint at one end of the bridge so that the prisms are directly facing the center of the static load test bridge span. The origin is the intersection of the center line of the two prisms and the center line of the bridge pier. The line is the Y axis, the vertical direction is the Z axis, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com