Method for correcting deviation of connecting surface of wind wheel system and transmission spindle of wind generating set

A technology for wind turbines and drive shafts, which is applied in the control of wind turbines, wind turbines, wind energy power generation, etc., can solve problems such as high safety risks, loss of power generation, and excessive labor, so as to reduce costs and increase efficiency. Loss of power generation, effect of reducing working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

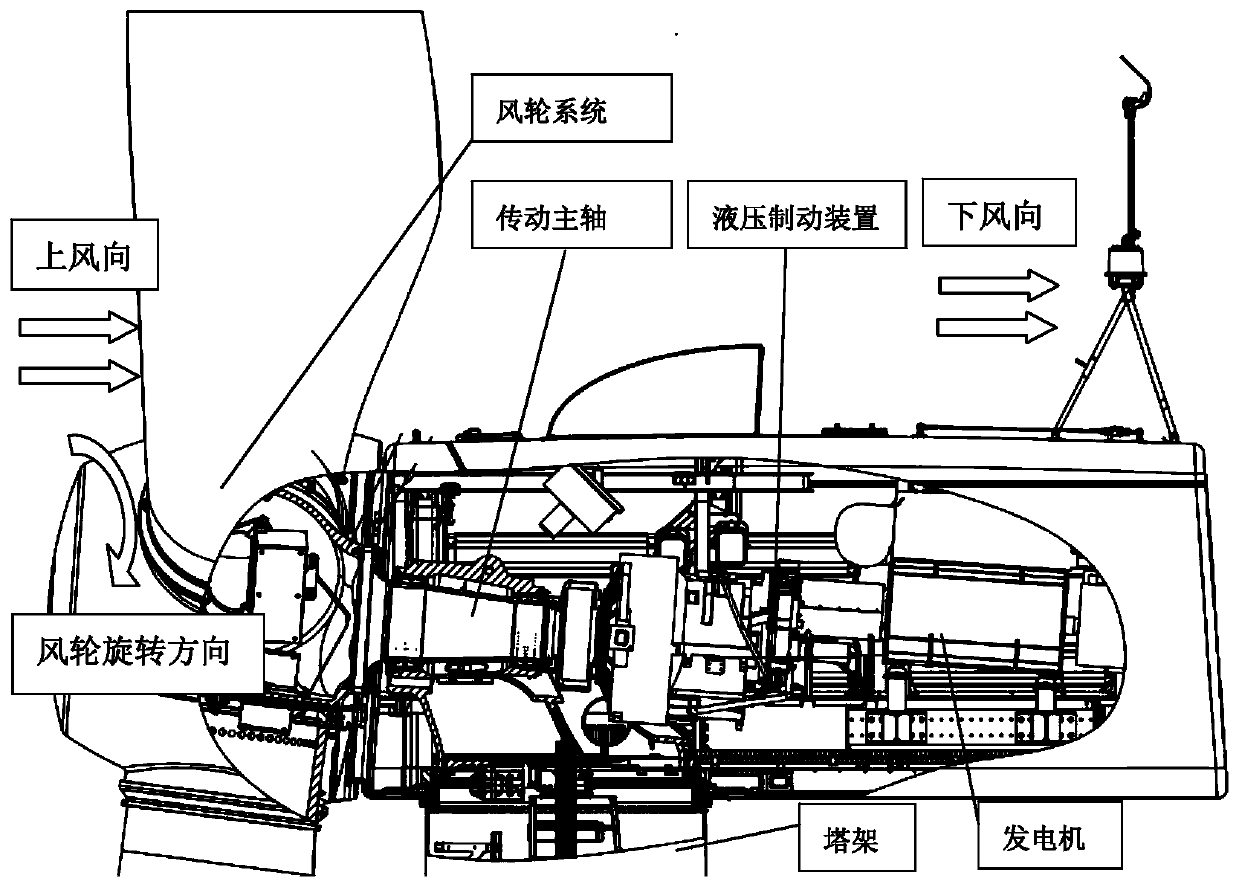

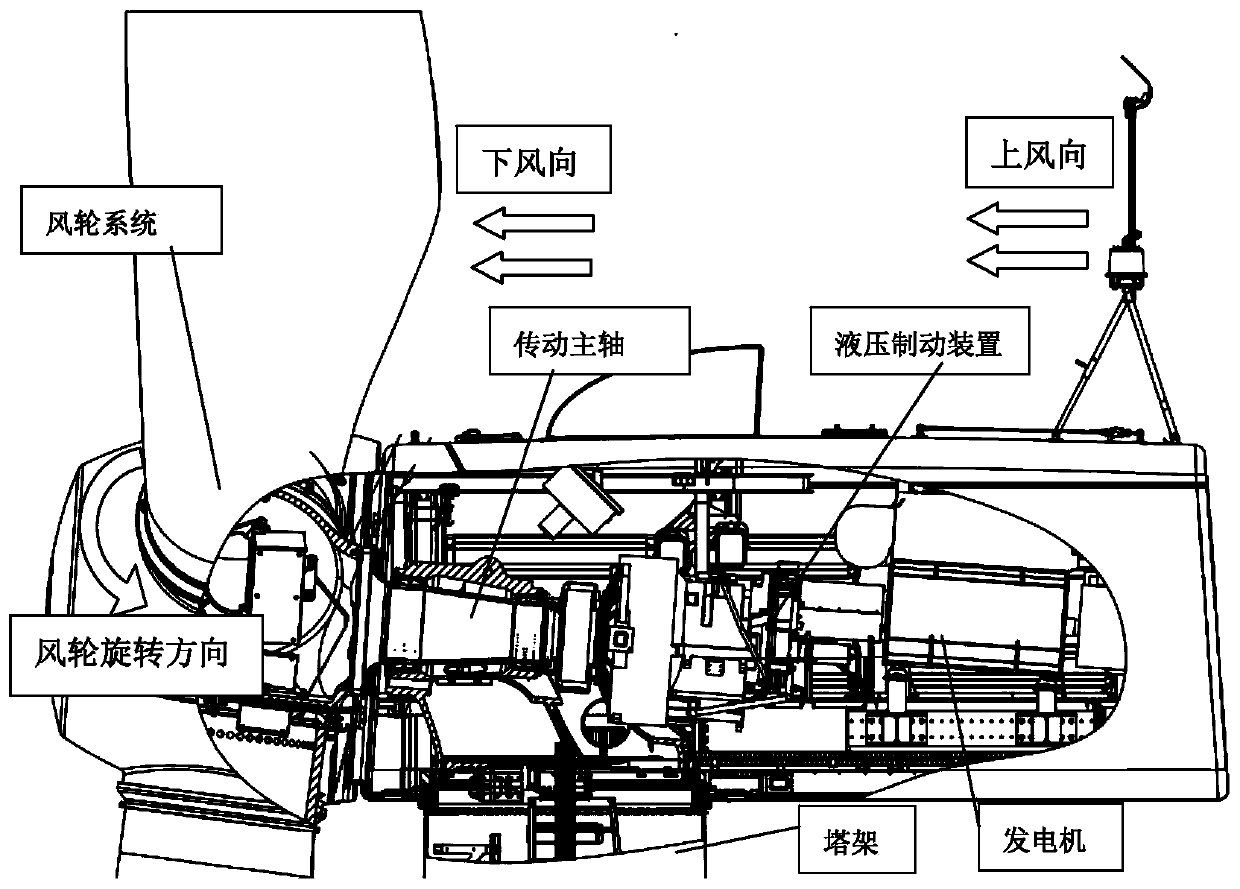

[0036] In a typical implementation of the present invention, a method for correcting the offset of the connection surface between the wind turbine system and the transmission main shaft of a wind power generating set is disclosed; the wind generating set involved in the present invention is such as figure 1 As shown, it mainly includes: wind wheel system (composed of hub and blades), transmission main shaft, yaw device, hydraulic brake device, generator, tower and so on. Under the wind force in the upwind direction, the wind rotor system rotates counterclockwise (viewed from the nacelle to the direction of the wind rotor system). According to the quality of the wind rotor system and the force of the wind load, calculate the range of the preload after the loosening of the high-strength fasteners connecting the wind rotor system and the drive shaft.

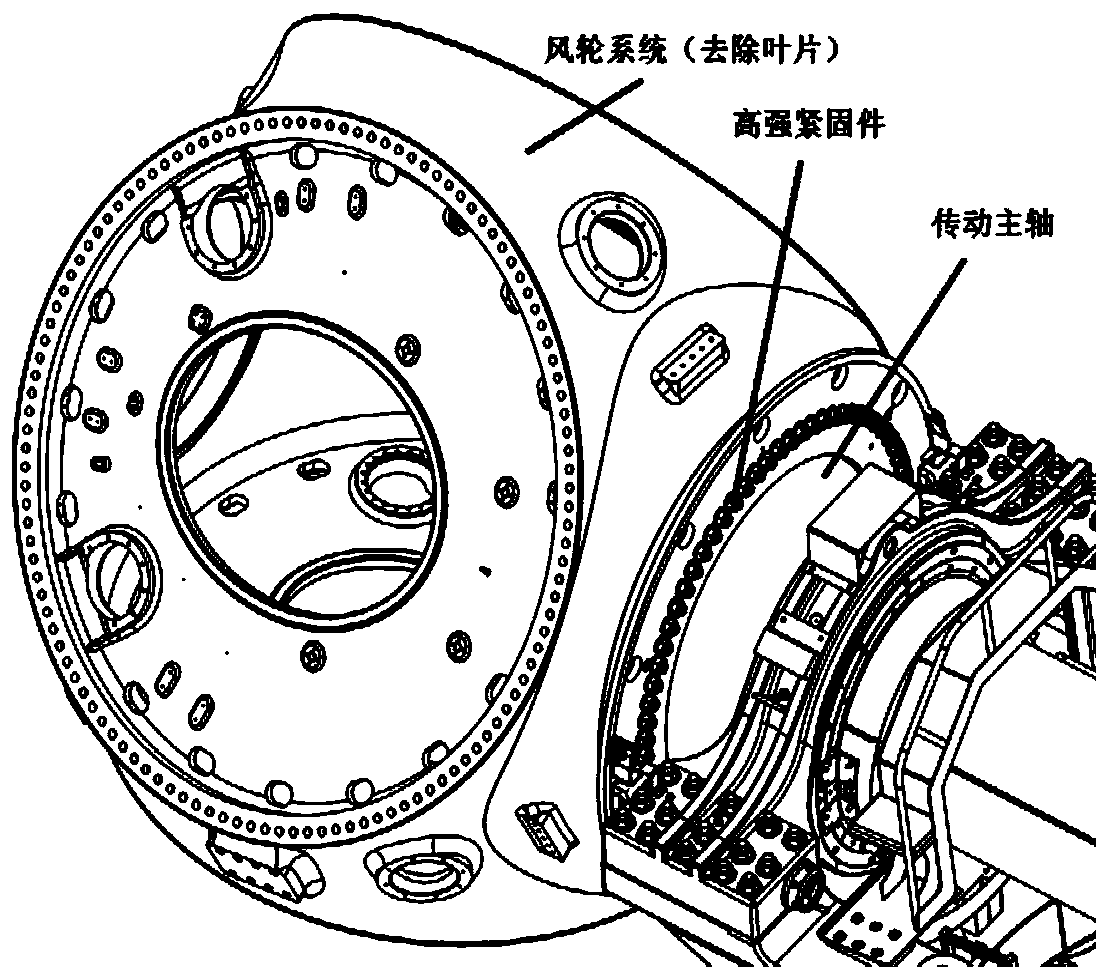

[0037] Such as figure 2 As shown in Fig. 1, the wind wheel system is used as the source component for converting wind energy in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com