Extrusion type buried rubber waterstop and construction method thereof

A technology of rubber waterstop and construction method, which is applied in water conservancy projects, artificial islands, underwater structures, etc., can solve problems such as disengagement of joints, waterstop flanging, and poor waterproof effect, so as to improve waterproofing Effect, strong connection, effect of increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

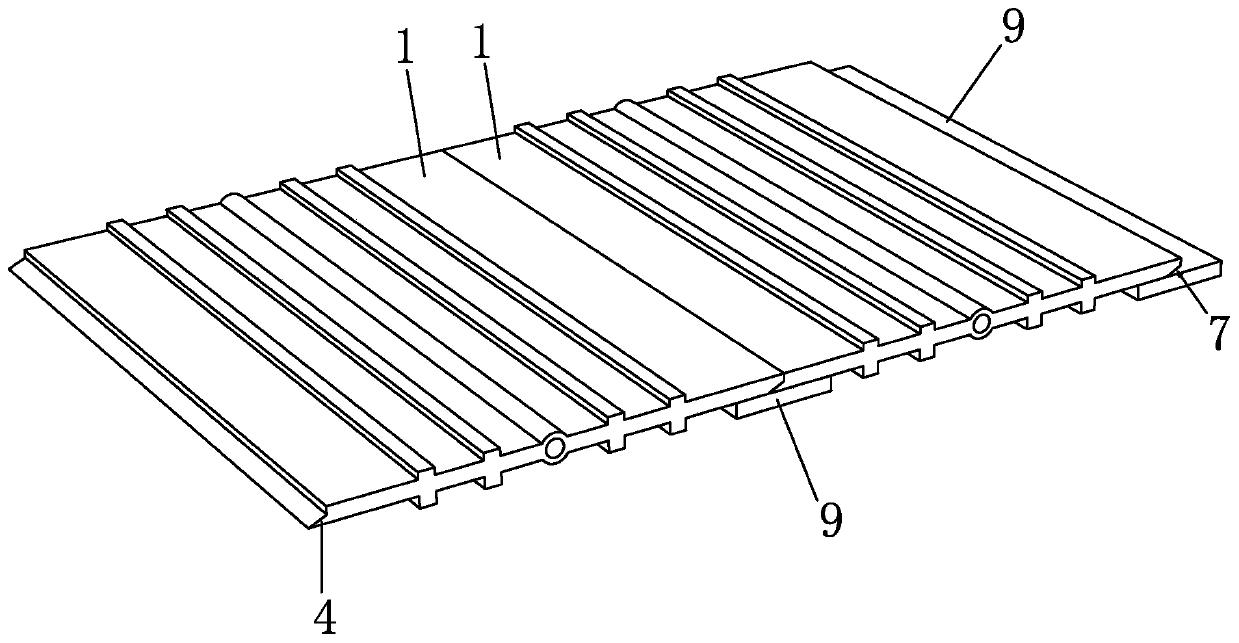

[0057] Such as Figure 1 to Figure 3 As shown, it is Embodiment 1 of the present invention,

[0058] The extrusion type buried rubber waterstop includes a body 1, the body 1 is provided with a waterstop strip 2, one side of the body 1 is provided with a first connection surface 3 and a connection protrusion 4, the first connection surface 3 and the connection protrusion The first connection slope 5 of the lifting device 4 is connected. The other side of the body 1 is provided with a second connection surface 6 and a connection groove 7 , the second connection surface 6 is connected with the second connection slope 8 of the connection groove 7 , and the connection protrusion 4 matches the connection groove 7 . The bottom of the other side of the main body 1 is provided with a horizontal connecting support block 9 , and the connecting supporting block 9 can be fixed on the bottom of the main body 1 by glue in the factory. The connection support block 9 is arranged below the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com