Asphalt laying equipment for municipal engineering buildings

An engineering and construction technology, applied in the field of municipal construction, can solve the problems of waste construction of asphalt, uncontrollable speed of asphalt outflow, inconvenience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

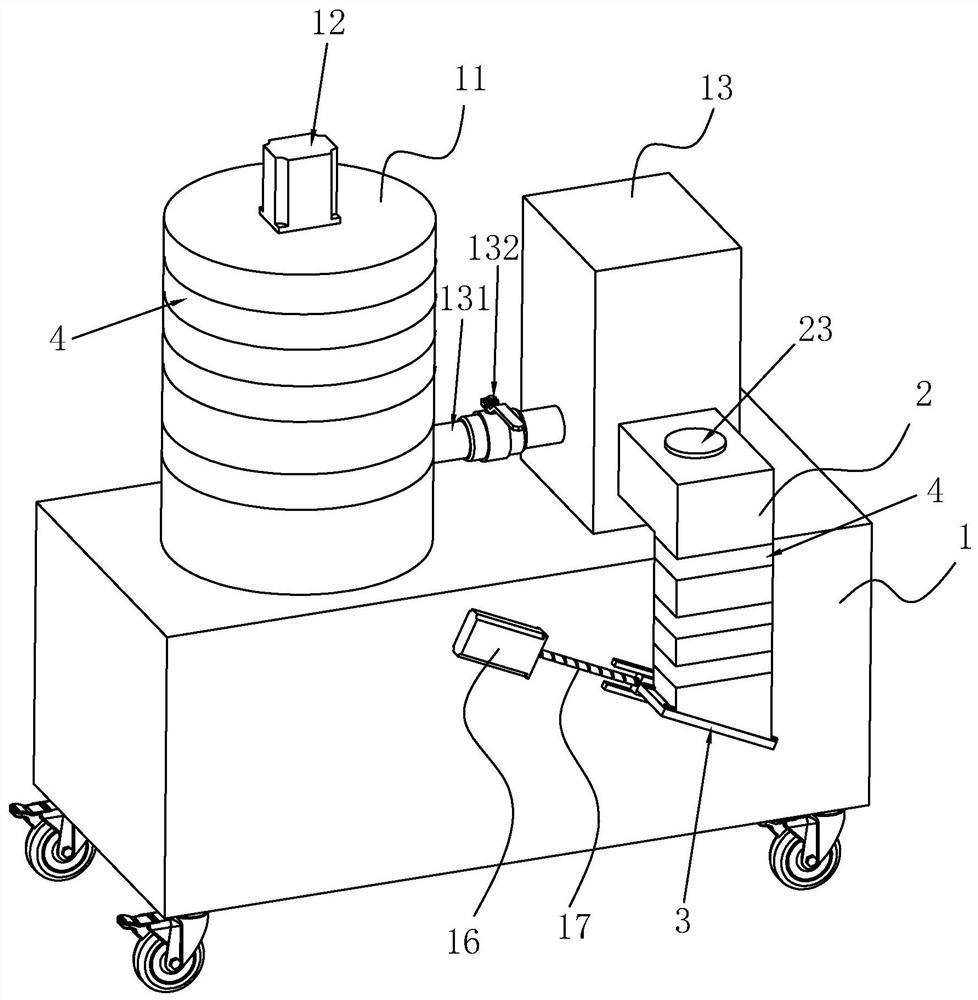

[0030] refer to figure 1 , is the asphalt laying equipment of a kind of municipal engineering building disclosed by the present invention, comprises body 1, is provided with stirring bin 11 on body 1, is provided with agitator 12 in the agitating bin 11, and agitator 12 is composed of agitating motor, agitating shaft, and The stirring paddle is composed of a heating device 4 arranged outside the stirring chamber 11, the heating device 4 is an electric heating belt arranged outside the stirring chamber 11, a storage chamber 13 is arranged on the body 1 and one side of the stirring chamber 11, and the storage chamber 13 is connected to the stirring chamber 11. The mixing bins 11 are connected, and a connecting pipe 131 is arranged between the storage bin 13 and the stirring bin 11 , and a control valve 132 is arranged on the connecting pipe 131 .

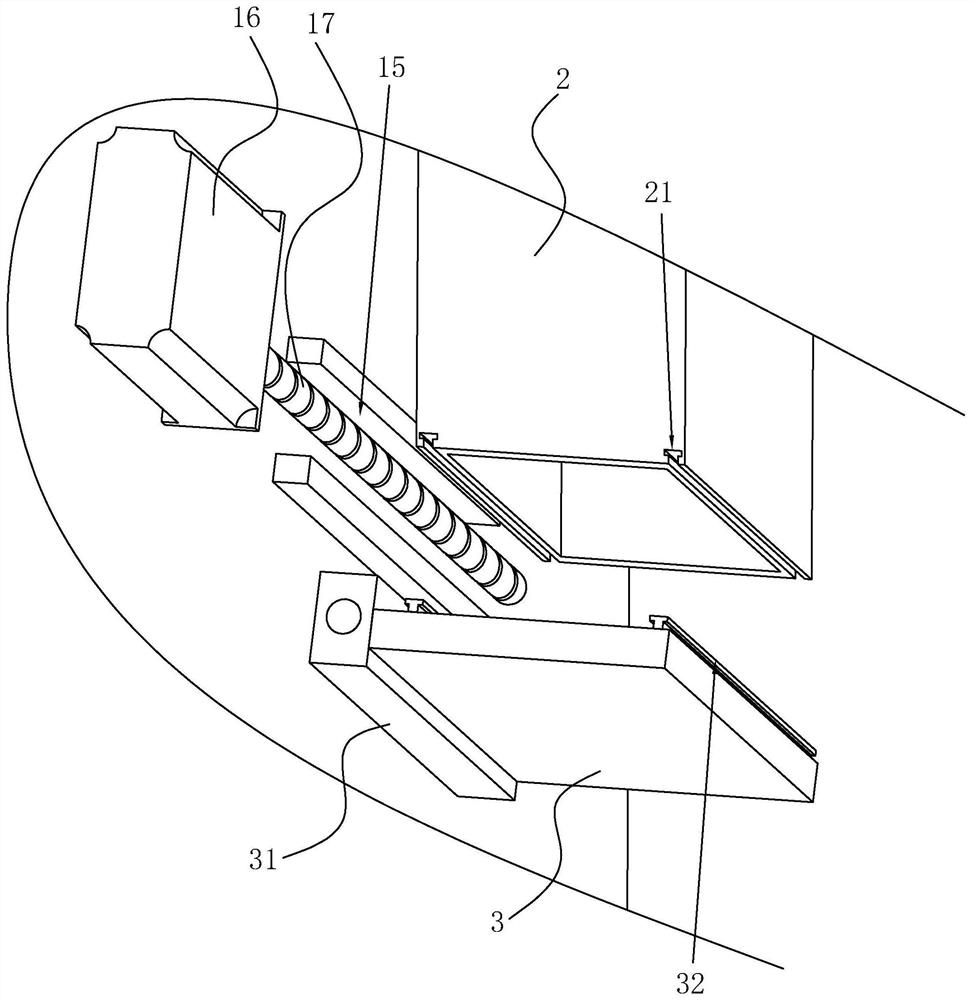

[0031] refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com