A functional compound dyeing acid

A kind of dyeing acid and functional technology, applied in dyeing, textiles and papermaking, etc., can solve the problems of poor neutralization ability, achieve the effect of reducing the dosage, shortening the dyeing time, and reducing the effect of yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A functional compound dyeing acid, which is composed of the following components in weight percentage: glacial acetic acid 22%, formic acid 3.5%, EDTA 1.8%, penetrant 0.3%, modified graphene oxide 0.08%, dispersant 0.32% and deionized water.

[0022] The dispersant is a silicon-containing hyperdispersant.

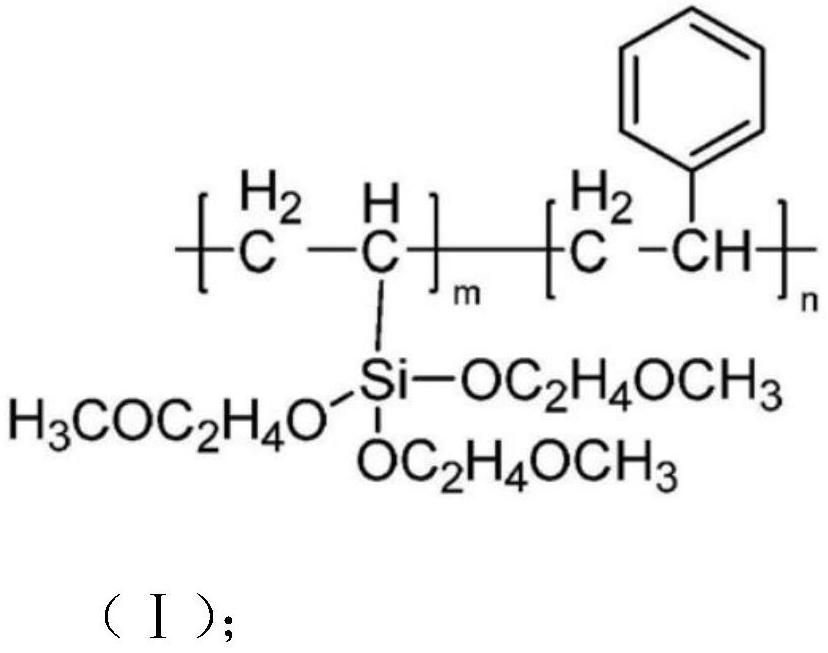

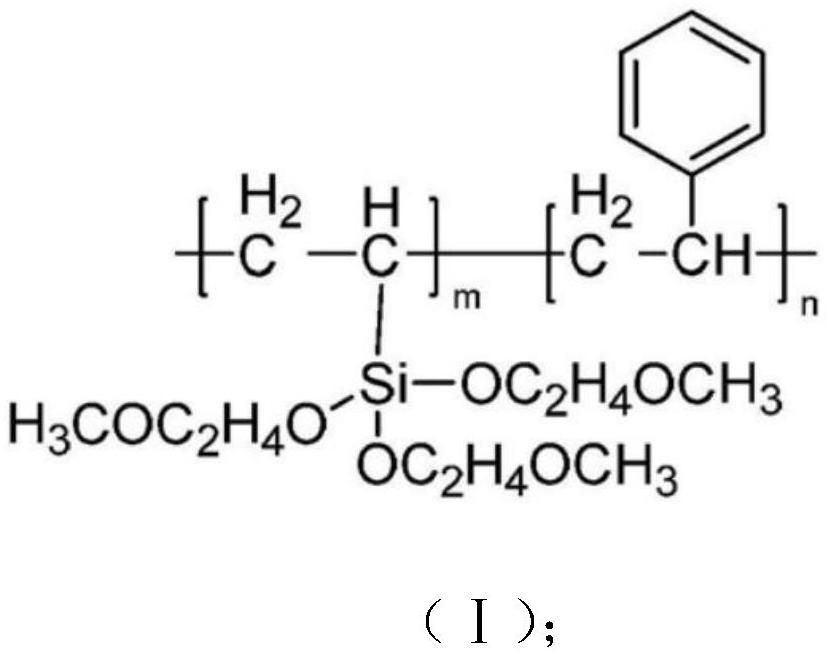

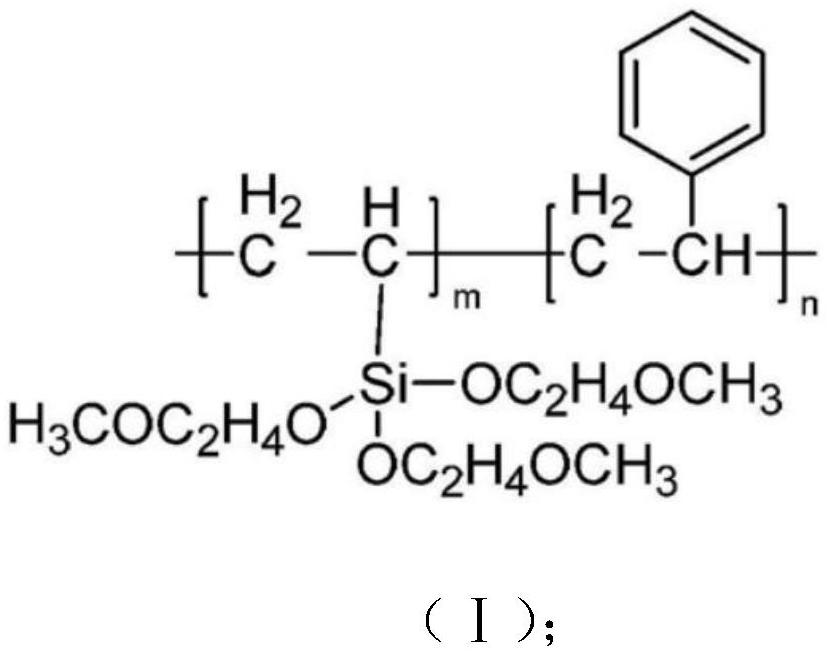

[0023] The molecular formula (I) of the silicon-containing hyperdispersant is:

[0024]

[0025] In formula (I), m and n are both between 10-100;

[0026] The modified graphene oxide is silicon-containing modified graphene oxide.

[0027] The preparation method of the silicon-containing modified graphene oxide comprises the following steps: adding 70 parts of ethanol, 15 parts of deionized water, 2 parts of γ-aminopropyltriethoxysilane, and 3 parts of orthosilicic acid into the container Ethyl ester, heat up to 50°C, add 5 parts of ammonia water with a mass fraction of 25%, stir for 2 hours, then add 5 parts of graphene oxide, continue the reaction for 1 hour, ...

Embodiment 2

[0029] A functional compound dyeing acid, which is composed of the following components in weight percentage: glacial acetic acid 25%, formic acid 2%, EDTA 2%, penetrant 0.2%, modified graphene oxide 0.12%, dispersant 0.2% and deionized water.

[0030] The dispersant is a silicon-containing hyperdispersant.

[0031] The molecular formula (I) of the silicon-containing hyperdispersant is:

[0032]

[0033] In formula (I), m and n are both between 10-100;

[0034] The modified graphene oxide is silicon-containing modified graphene oxide.

[0035] The preparation method of the silicon-containing modified graphene oxide comprises the following steps: adding 85 parts of ethanol, 15 parts of deionized water, 3 parts of γ-aminopropyltriethoxysilane, and 2 parts of orthosilicic acid into the container Ethyl ester, heat up to 70°C, add 5 parts of acetic acid with a mass fraction of 20%, stir for 2 hours, then add 5 parts of graphene oxide, continue the reaction for 2 hours, cool t...

Embodiment 3

[0037] A functional compound dyeing acid, which is composed of the following components by weight percentage: glacial acetic acid 18%, formic acid 5%, EDTA 1%, penetrant 0.5%, modified graphene oxide 0.05%, dispersant 0.5% and deionized water.

[0038] The dispersant is a silicon-containing hyperdispersant.

[0039] The molecular formula (I) of the silicon-containing hyperdispersant is:

[0040]

[0041] In formula (I), m and n are both between 10-100;

[0042] The modified graphene oxide is silicon-containing modified graphene oxide.

[0043] The preparation method of the silicon-containing modified graphene oxide comprises the following steps: adding 80 parts of ethanol, 25 parts of deionized water, 2.5 parts of γ-aminopropyltriethoxysilane, and 3.5 parts of orthosilicic acid into the container Ethyl ester, heat up to 40°C, add 5 parts of ammonia water, stir for 4 hours, then add 5 parts of graphene oxide, continue the reaction for 3 hours, cool to room temperature, fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com