A kind of phase change thermally conductive material and preparation method thereof

A phase change thermal conductivity, graphite powder technology, applied in the field of thermal conductivity materials, can solve the problems of low temperature, inability to meet requirements, inapplicability, etc., to achieve high flame retardant level, improve heat dissipation effect, and efficient thermal management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

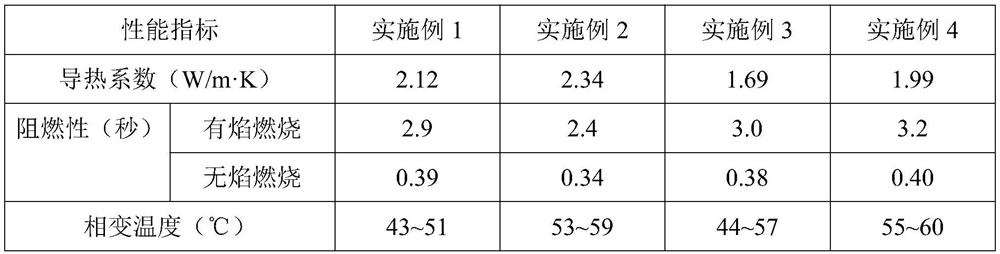

Examples

Embodiment 1

[0031] Bake 10 parts of graphite powder, 5 parts of aluminum nitride powder, 10 parts of zinc oxide powder, 5 parts of aluminum oxide powder, 10 parts of magnesium oxide, and 5 parts of glass fiber in an oven at 100°C for 10 hours, then put them into a ball mill and mill them for 12 hours to disperse the powder material evenly, add 5 parts of flame retardant, 3 parts of coupling agent, and 1 part of toughening agent, and continue ball milling for 6 hours; graphite powder, aluminum nitride powder, zinc oxide powder, aluminum oxide powder, magnesium oxide powder The particle size is 100nm, and the particle size of glass fiber is 1μm; the flame retardant is a mixture of oligopolyammonium phosphate, brominated polystyrene, and antimony trioxide, and the mass ratio of the three is 1:1:1; the coupling agent It is an aluminate coupling agent;

[0032] Add 95 parts of paraffin, 25 parts of polyethylene, and 5 parts of ethylene-vinyl acetate copolymer into a stirring device with a temp...

Embodiment 2

[0034] Bake 10 parts of graphite powder, 5 parts of aluminum nitride powder, 10 parts of zinc oxide powder, 5 parts of aluminum oxide powder, 10 parts of magnesium oxide, and 5 parts of glass fiber in an oven at 80°C for 12 hours, then put them into a ball mill and mill them for 8 hours , to disperse the powder evenly, add 10 parts of flame retardant, 1 part of coupling agent, and 3 parts of toughening agent, and continue ball milling for 4 hours; graphite powder, aluminum nitride powder, zinc oxide powder, aluminum oxide powder, magnesium oxide The particle size of the glass fiber is 50nm, and the particle size of the glass fiber is 5μm; the flame retardant is a mixture of oligopolyammonium phosphate, brominated polystyrene, and antimony trioxide, and the mass ratio of the three is 1:1:1; coupling The agent is a silane coupling agent;

[0035] Add 105 parts of paraffin, 10 parts of polyethylene, and 10 parts of ethylene-vinyl acetate copolymer into a stirring device with a te...

Embodiment 3

[0037]Bake 6 parts of graphite powder, 10 parts of aluminum nitride powder, 7 parts of zinc oxide powder, 5 parts of aluminum oxide powder, 7 parts of magnesium oxide, and 9 parts of glass fiber in an oven at 90°C for 11 hours, then put them into a ball mill and mill them for 9 hours , to disperse the powder evenly, add 7 parts of flame retardant, 2 parts of coupling agent, and 2 parts of toughening agent, and continue ball milling for 5 hours; graphite powder, aluminum nitride powder, zinc oxide powder, aluminum oxide powder, magnesium oxide The particle size of the glass fiber is 60nm, and the particle size of the glass fiber is 7μm; the flame retardant is a mixture of oligopolyammonium phosphate, brominated polystyrene, and antimony trioxide, and the mass ratio of the three is 1:1:1; coupling The agent is an aluminate coupling agent;

[0038] Add 105 parts of paraffin wax, 15 parts of polyethylene, and 8 parts of ethylene-vinyl acetate copolymer into a stirring device with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com