Method for synthesizing 4-hydroxy-4'-isopropoxy-diphenyl sulfone compound by micro-channel reactor

A technology of microchannel reactor and isopropoxy, which is applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve the problems of long reaction time, high reaction temperature, and low conversion rate, and achieve the goal of reaction time Short, high yield, high conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

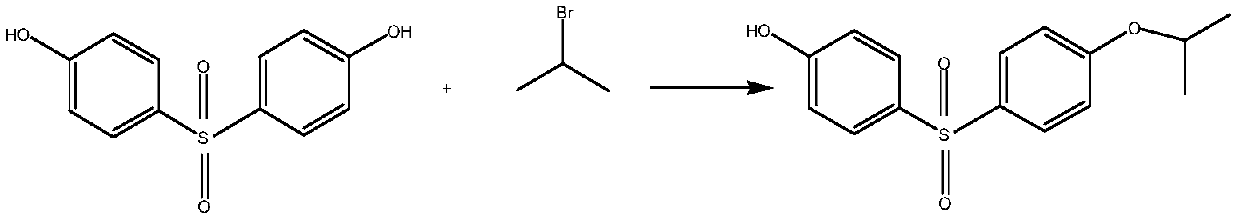

[0020] Reaction equation:

[0021]

[0022] Dissolve 20 grams of bisphenol S in 3.2 grams of sodium hydroxide and 50 milliliters of aqueous solution in a three-necked flask, add 9.8 grams of 2-bromopropane in another one-necked flask, and pass it into the microchannel reactor with a metering pump respectively, the reaction temperature 60 degrees, the reaction time is 5 minutes. The obtained reaction liquid was added into a three-necked flask, and the precipitation was carried out at room temperature for 5-10 hours. Filter, wash with water until neutral, and dry to obtain 21.5 g of white powder. Content 99.4%, yield 92.0%.

Embodiment 2

[0023] Embodiment 2: the difference between this example and embodiment 1 is:

[0024] In this example, 20 grams of bisphenol S are dissolved in 3.2 grams of sodium hydroxide and 50 milliliters of aqueous solution in a three-necked flask, and 9.8 grams of 2-bromopropane are added in another one-necked flask, which are passed into the microchannel reactor with metering pumps respectively. The reaction temperature is 60 degrees, and the reaction time is 4 minutes. The obtained reaction liquid was added into a three-necked flask, and the precipitation was carried out at room temperature for 5-10 hours. Filter, wash with water until neutral, and dry to obtain 21.1 g of white powder. Content 99.2%, yield 90.5%.

Embodiment 3

[0025] Embodiment 3: the difference between this example and embodiment 1 is:

[0026] In this example, 20 grams of bisphenol S are dissolved in 3.2 grams of sodium hydroxide and 50 milliliters of aqueous solution in a three-necked flask, and 9.8 grams of 2-bromopropane are added in another one-necked flask, which are passed into the microchannel reactor with metering pumps respectively. The reaction temperature is 60 degrees, and the reaction time is 3 minutes. The obtained reaction liquid was added into a three-necked flask, and the precipitation was carried out at room temperature for 5-10 hours. Filter, wash with water until neutral, and dry to obtain 20.6 g of white powder. Content 99.1%, yield 88.3%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap