Treatment system and treatment process for wastewater containing fluorine and phosphorus

A technology of treatment system and treatment process, which is applied in the field of industrial wastewater treatment, can solve the problems of small amount of treated wastewater, large amount of sludge generated, and difficult discharge of wastewater up to standard, and achieve the effect of reducing operating costs and reducing the amount of sludge generated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

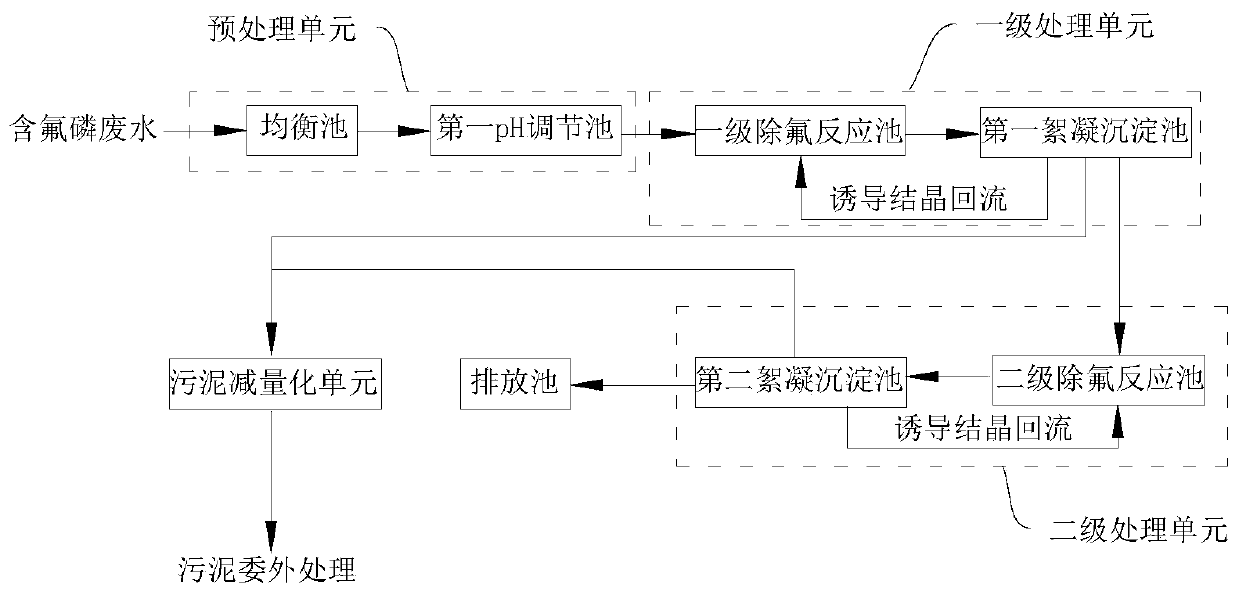

[0031] Please refer to figure 1 , The treatment system of fluorine and phosphorus-containing wastewater according to the embodiment of the present invention includes: a pretreatment unit, a primary treatment unit, a secondary treatment unit, a discharge pond and a sludge reduction unit.

[0032] The pretreatment unit includes: a balance tank and a first pH adjustment tank connected in sequence.

[0033] The primary treatment unit includes: a primary defluorination reaction tank communicated with the outlet of the first pH adjustment tank, and a first flocculation sedimentation tank communicated with the outlet of the primary defluorination reaction tank. The outlet of the first flocculation sedimentation tank is respectively connected with the primary defluorination reaction tank, the secondary treatment unit and the sludge reduction unit. The outlet of the first flocculation-sedimentation tank includes: a first sludge outlet connected to the primary defluorination reaction t...

Embodiment 2

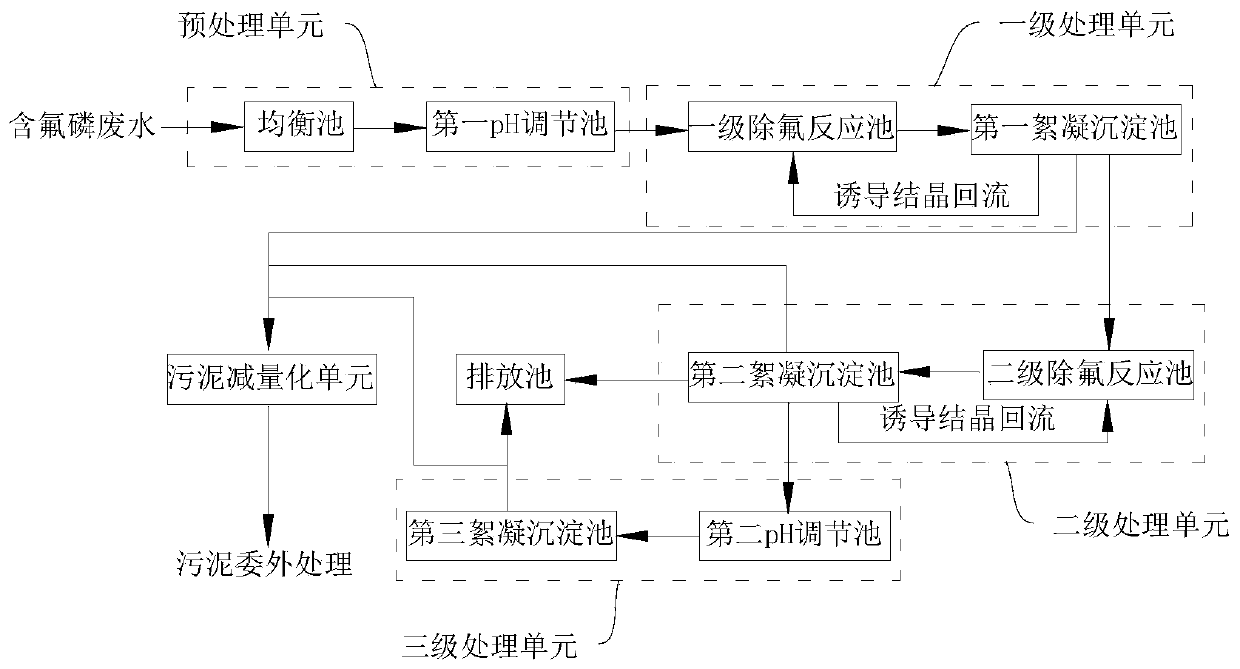

[0036] Please refer to figure 2 , the treatment system for fluorine and phosphorus-containing wastewater according to the embodiment of the present invention includes all the structures of embodiment 1, and also includes a tertiary treatment unit. The tertiary treatment unit includes: a second pH adjustment tank communicated with the second outlet of the second flocculation-settling tank, and a third flocculation-settling tank communicated with the outlet of the second pH adjustment tank. The outlet of the third flocculation sedimentation tank is connected with the discharge tank and the sludge reduction unit respectively. The outlet of the third flocculation-sedimentation tank includes: a third discharge outlet connected to the discharge tank and a third sludge discharge outlet connected to the sludge reduction unit. .

Embodiment 3

[0038] A treatment process for fluorine-containing phosphorus wastewater, characterized in that, the treatment system of Embodiment 1 is used to process, and it may further comprise the steps:

[0039] (1) The fluorine-containing phosphorus wastewater to be treated is passed into the pretreatment unit, and the wastewater is homogenized and evenly measured in the equalization tank and then entered into the first pH adjustment tank to adjust the pH of the wastewater to 6. Adjusted with 30wt% NaOH solution, the same is true for subsequent examples.

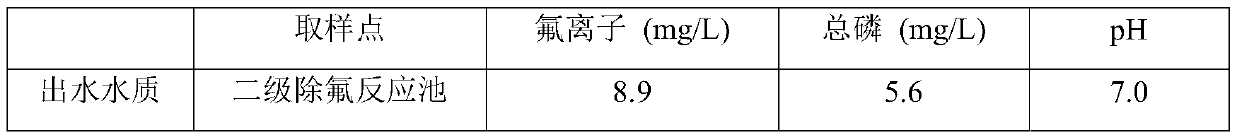

[0040] (2) The wastewater treated by the pretreatment unit is introduced into the primary treatment unit, and after being treated in the primary defluorination reaction tank, it enters the first flocculation sedimentation tank, and the dosage and The molar ratio of fluoride ions in the wastewater is calcium salt with a molar ratio of 8:1, and a mixed flocculant consisting of 50 mg / L PAC and 2 mg / L PAM is added to the first flocculati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com