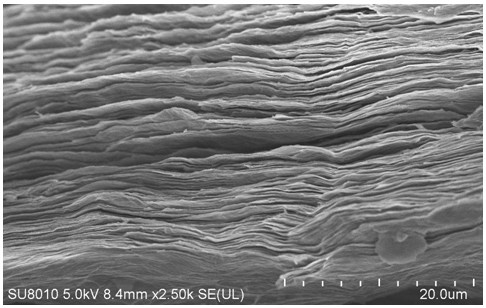

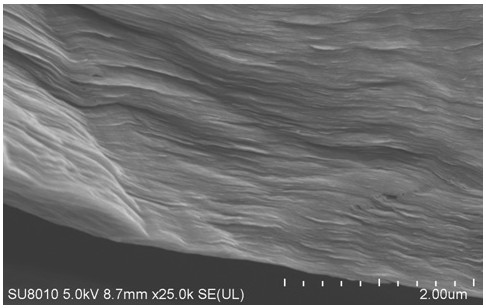

A kind of ultra-high thermal conductivity graphene thick film and preparation method thereof

A heat-conducting graphite and graphene technology, applied in the direction of graphene, chemical instruments and methods, nano-carbon, etc., can solve the problem of poor thermal conductivity of graphene thick film, unstable two-dimensional planar structure, and inability to guarantee the consistency and consistency of graphene sheets. Problems such as close arrangement, to overcome structural collapse, close arrangement and avoid energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) After washing the oxide ink of C / O = 1.67 of the solid content of 44.6%, after deionized water, diluted with deionized water to the graphite concentration of 10 mg / ml, take 200ml mixed liquid, 12 hours The water bath is ultrasonically stirred at a rate of 300r / min.

[0032] (2) Press HCl and NH in HCl solution to mass fraction. 4 The amount ratio of the CL substance is 1:23 to add NH 4 CL powder, configure HCl and NH 4 CL mixed solution, add HCl and NH to the oxide oxide hydrocene 4 The mixed solution of Cl is reduced to 1 to 1, and stirred at a rotational speed of 300 r / min for 30 minutes.

[0033] (3) Anhydrous ethanol is added to the oxide in grapiene slurry, and anhydrous ethanol is added in accordance with the proportion of ethanol volume ratio 1: 4, and stirred at a rotational speed of 300 r / min for 30 minutes.

[0034] (4) After the bottom of the rectangle of 8 cm * 8cm is sealed, the oxidized grapite slurry is poured into the mold along the mold wall, ...

Embodiment 2

[0038] (1) After washing the oxide ink of C / O = 1.67 of 44.6% by deionized water to neutral, diluted with deionized water to the graphite concentration of 10 mg / ml, take 400 ml of mixed liquid, 12 hours The water bath is ultrasonically stirred at a rate of 300r / min.

[0039] (2) Press HCl and NH in HCl solution to mass fraction. 4 The amount ratio of the CL substance is 1:23 to add NH 4 CL powder, configure HCl and NH 4 CL mixed solution, add HCl and NH to the oxide oxide hydrocene 4 The mixed solution of Cl is reduced to 1 to 1, and stirred at a rotational speed of 300 r / min for 30 minutes.

[0040] (3) Anhydrous ethanol is added to the oxide in grapiene slurry, and anhydrous ethanol is added in accordance with the proportion of ethanol volume ratio 1: 4, and stirred at a rotational speed of 300 r / min for 30 minutes.

[0041] (4) After the bottom of the rectangle of 5 cm * 5cm is sealed in the bottom of the mold of 5 cm * 5cm, the oxide ink alkylene slurry is poured int...

Embodiment 3

[0045] (1) After washing the oxide ink of C / O = 1.67 with a solid content of 44.6%, after deionized water, diluted with deionized water to a graphite concentration of 10 mg / ml, take 600 ml of mixed liquid, 12 hours The water bath is ultrasonically stirred at a rate of 300r / min.

[0046] (2) Press HCl and NH in HCl solution to mass fraction. 4 The amount ratio of the CL substance is 1:23 to add NH 4 CL powder, configure HCl and NH 4 CL mixed solution, add HCl and NH to the oxide oxide hydrocene 4 The mixed solution of Cl is reduced to 1 to 1, and stirred at a rotational speed of 300 r / min for 30 minutes.

[0047] (3) Anhydrous ethanol is added to the oxide in grapiene slurry, and anhydrous ethanol is added in accordance with the proportion of ethanol volume ratio 1: 4, and stirred at a rotational speed of 300 r / min for 30 minutes.

[0048] (4) After the bottom of the rectangle of 5 cm * 5cm is sealed in the bottom of the mold of 5 cm * 5cm, the oxide ink alkylene slurry i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com