Polyethylene (PE) thin film blow molding machine

A technology of film blow molding and polyethylene, applied in the field of blow molding equipment, can solve the problems of incapable and efficient processing, increase the risk factor of personnel, etc., and achieve the effect of high-efficiency extrusion process, simple equipment structure, and continuous improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

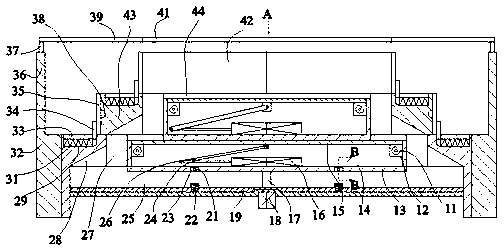

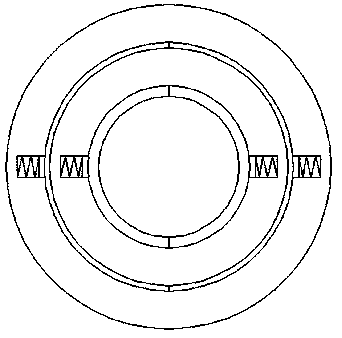

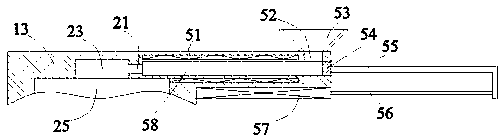

[0022] Such as Figure 1-Figure 3 As shown, the present invention is described in detail. For the convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship are the same. A polyethylene (PE) film blow molding machine of the present invention includes a fixed box 32, and the cooperating connection spring 31 is provided with several stacked settings for blow molding. Blowing device, the bottom molding blowing device is provided with a pushing and pouring device for pouring hot-melt polyethylene into the molding blowing device, and the upper end of the fixed box 32 is fixed with a symmetrical push cylinder 36, The power connection in the said push cylinder 36 is provided with a telescopic rod 37, and the upper end surface of the telescopic rod 37 is fixed with a top support rod 39, and the outer surface of the top support rod 39 is fixed with a connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com