Method for producing and guiding carbon fiber by using high-temperature carbonization furnace and high-temperature carbonization furnace thereof

A high-temperature carbonization furnace and high-temperature carbonization technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve problems such as energy waste and loss, and achieve the effects of reducing production costs, high yield and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

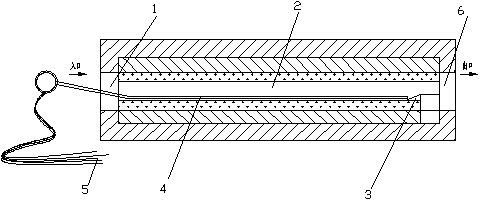

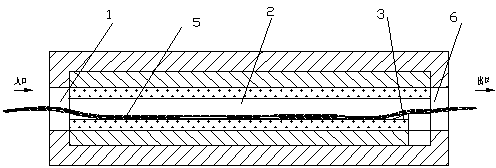

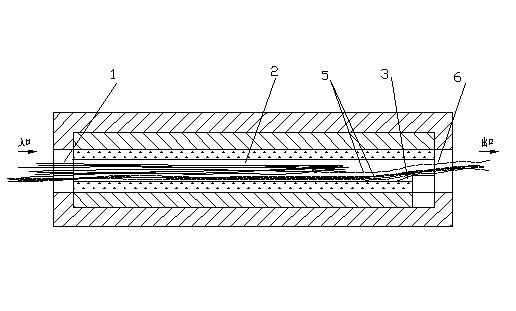

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

[0013] refer to Figure 1-Figure 3 , the high-temperature carbonization furnace carbon fiber production lead wire method of the present invention comprises a high-temperature carbonization furnace, the production temperature of which is 900~1400° C., a nickel-chromium metal wire 4 is used as a pulling tool, and the rear end of the pulling tool is tied with A plurality of carbon fiber graphitized ropes 5, and the traction device for securing several carbon fiber graphitized ropes 5 are passed through the entrance 1 of the high-temperature carbonization furnace, and then passed through the outlet 6, so that the carbon fiber graphitized ropes 5 penetrate and stay in the high temperature The two ends of the carbonization furnace separate several carbon fiber graphitization ropes 5 staying in the high temperature carbonization furnace from the traction device, and the quanti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com