Traction system and method for rapid replacement of flexible belt of long-distance overhead belt conveyor

A traction system and belt conveyor technology, applied in the direction of conveyor objects, transportation and packaging, rollers, etc., can solve the problems that large-tonnage belts cannot be lifted to high positions, affect the normal operation of adjacent belt conveyors, and affect the production efficiency of enterprises , to achieve the effects of rapid traction work, shortened replacement time, and flexible adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

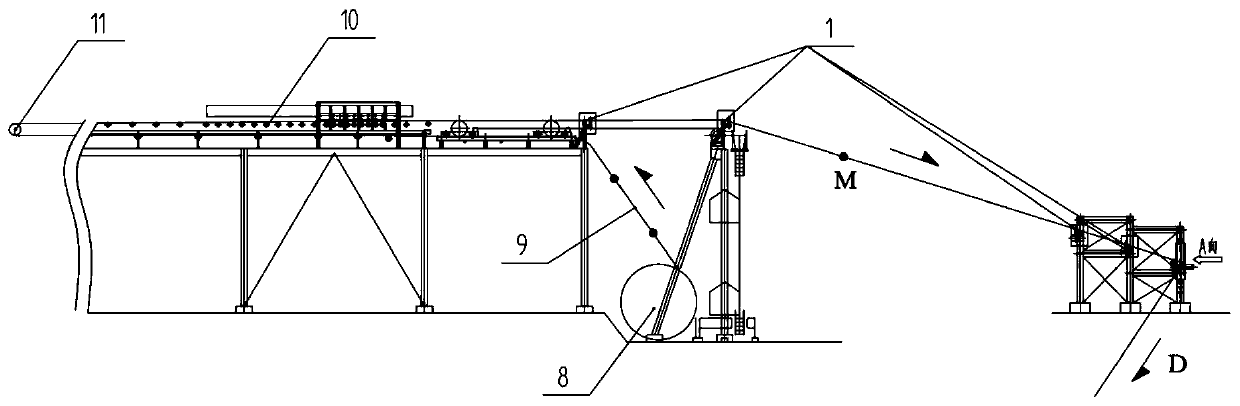

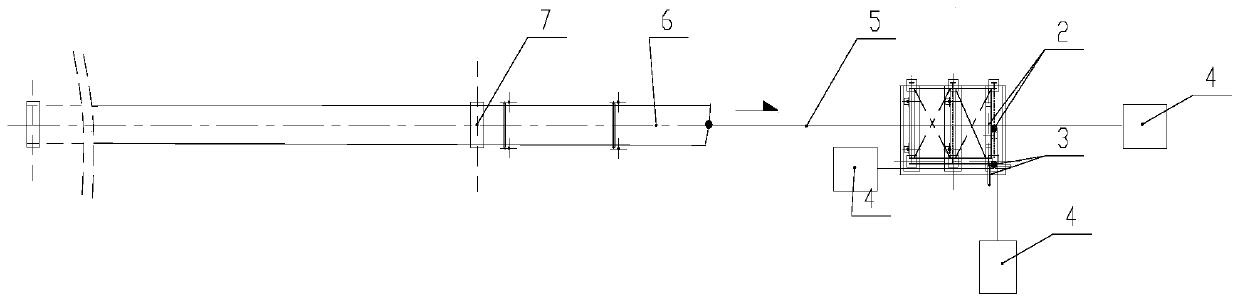

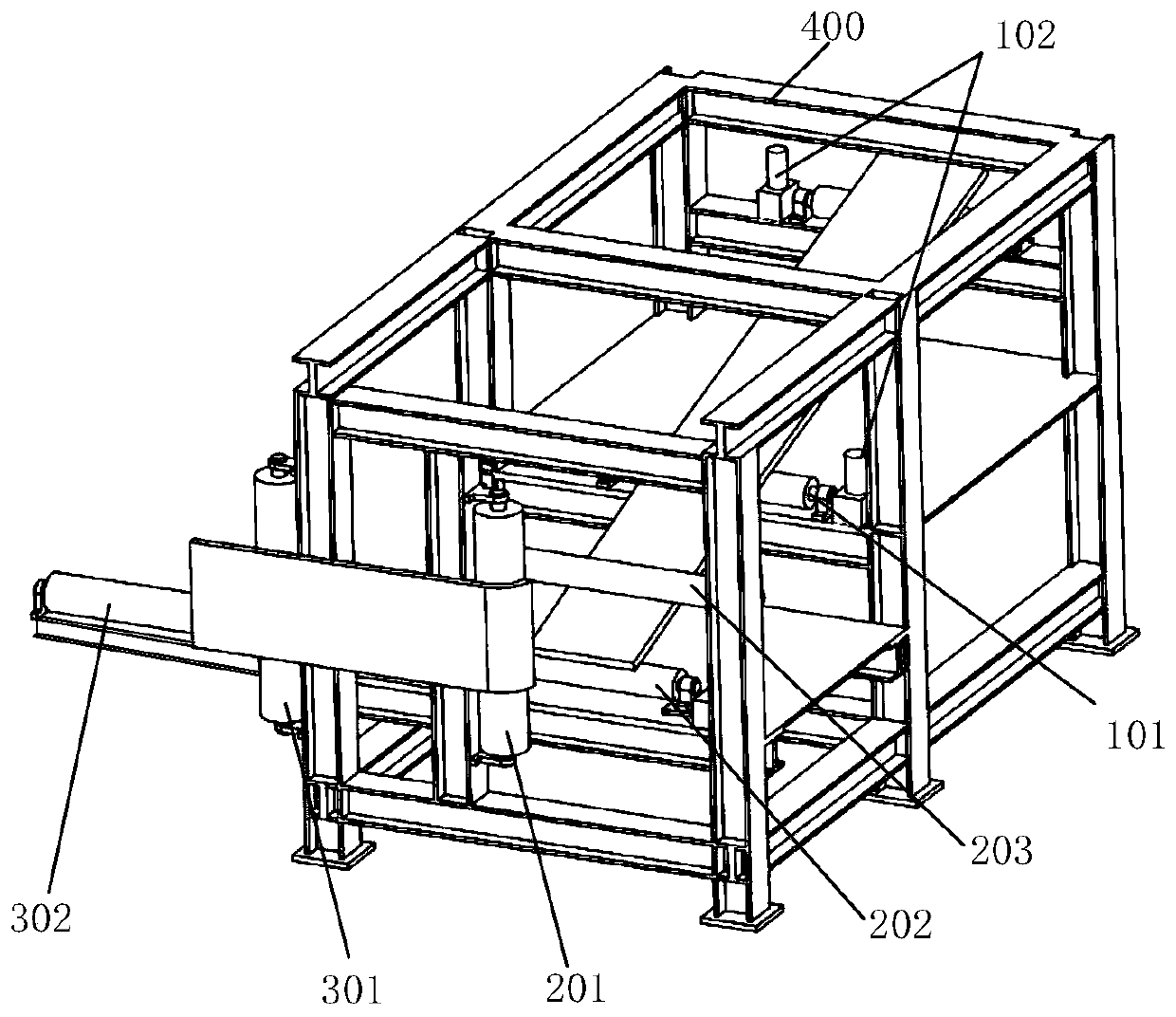

[0041] The traction and guiding device of the conveyor belt has been successfully applied to the elevated long-distance belt conveyor of the coal unloading system. Its basic parameters: the installation height of two parallel belts from the ground conveyor: H = 9.5 meters, and the horizontal length: L = 694 m, the total installation length of the conveyor belt: 1525 meters, the conveyor belt specification: ST1250 high-strength steel wire belt, the bandwidth: 1800mm. In order to ensure the smooth start of the initial traction condition of the conveyor belt and to stop in time when abnormalities are found, and to ensure that the belt is under control, the traction speed of the belt is set at 0.2m / s. To start smoothly, the starting acceleration is taken as 0.1m / s2.

[0042] By adopting the new-type centralization-changing traction device and traction system, the straight-line distance of the available traction site exceeds 200 meters. When the belt is replaced as a whole by using...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com