Device and method for preparing ultra-long aging-resistant melt-blown level polypropylene material and obtained material thereof

A polypropylene material and polypropylene technology, applied in the field of polymer material preparation and processing, can solve the problems of short service life and poor aging resistance of melt-blown polypropylene, so as to solve the problem of poor aging resistance, eliminate side reactions, improve The effect of degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Example 1: Preparation of ultra-long aging-resistant meltblown grade polypropylene with a melt flow rate of 150

[0064] The mass fraction of the degradation agent needs to be finally determined through multiple tests according to the requirements of the melt flow rate of the material. Other raw materials and mass fractions are shown in Table 1 below:

[0065] Table 1 Example 1 Raw materials and mass fraction

[0066] raw material Polypropylene 1 Polypropylene 2 Antioxidant 1010 Antioxidant 168 Degradant 101 parts by mass 100 2 0.2 0.2 Obtained by experiment

specific Embodiment approach

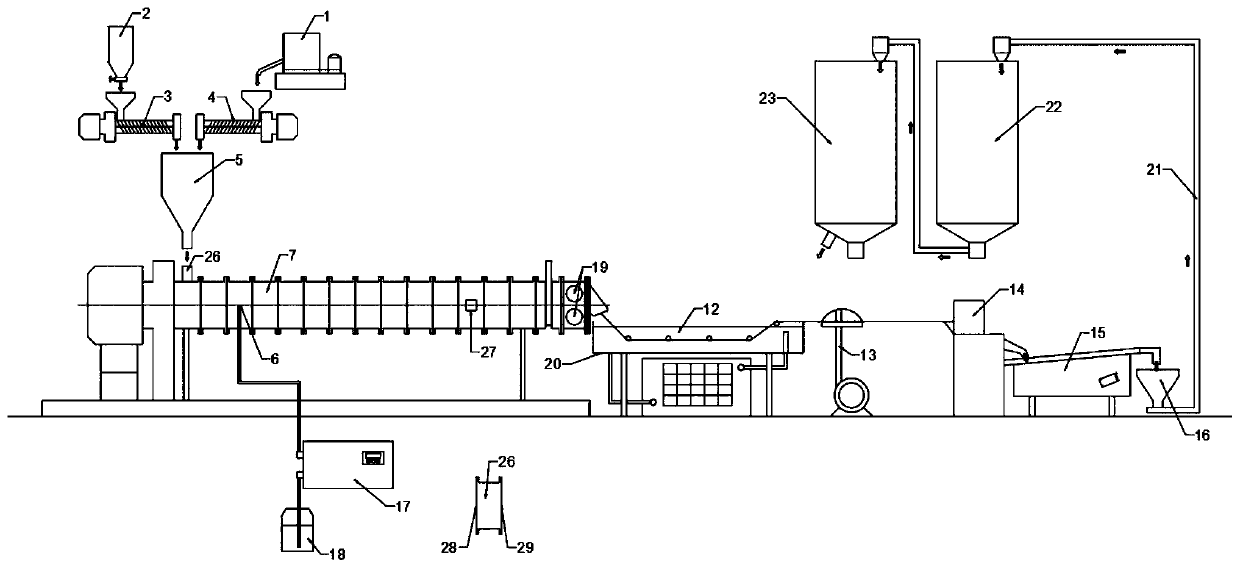

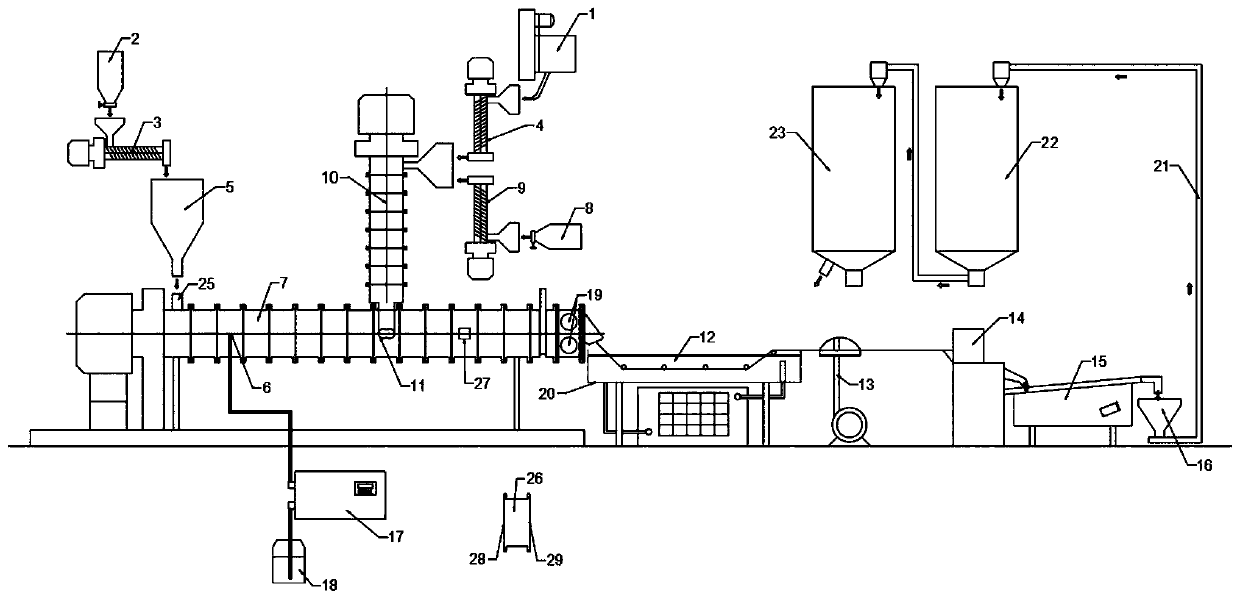

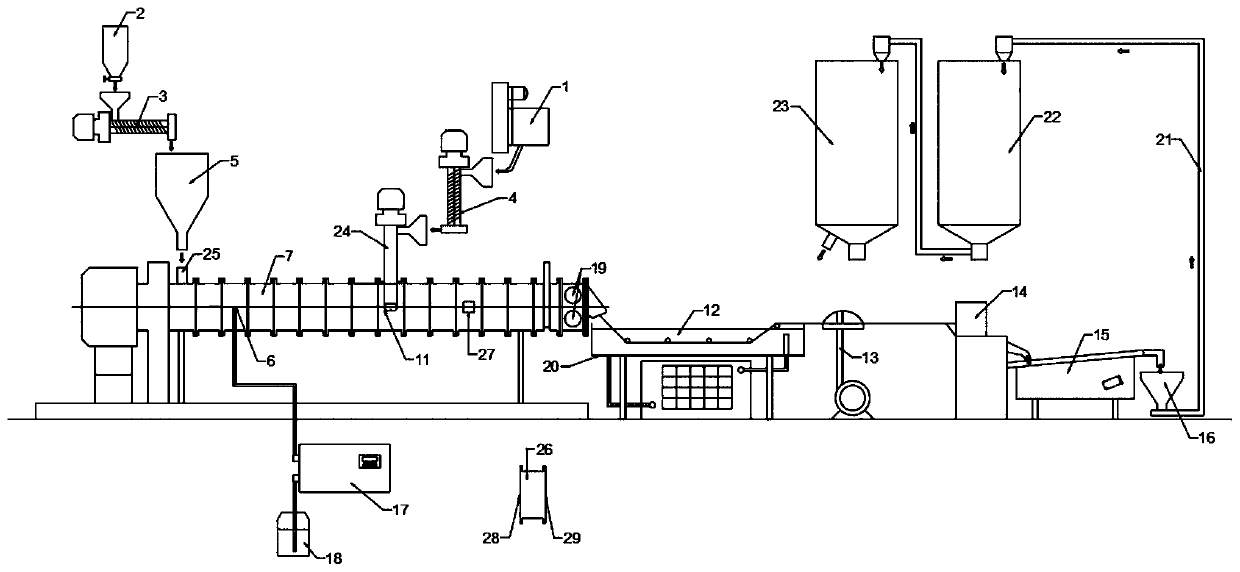

[0067] Specific embodiment: the process route is as attached figure 2 As shown, polypropylene 1 is placed in the first online feeding bin 2, and is added to a reactive twin-screw extruder with an aspect ratio of 56 through a feed hopper 5 at a uniform rate of 100 kg / h through a first loss-in-weight scale 3. In 7, the screw speed of the reactive twin-screw extruder is 250 rpm, and the degradation agent 101 in the liquid storage tank 18 passes through the liquid loss-in-weight scale 17 at the output of 0.1 kg / h through the reactive twin-screw extruder No. 1. The liquid injection port 6 of the third zone is injected into the reaction-type twin-screw extruder 7 at a constant speed, and the antioxidant 1010 and the antioxidant 168 are added to the mixer 1 at the mass ratio (1:1) shown in Table 1. Mixing at 100 rpm in the machine for 5min, then the antioxidant mixture was added to the pre-dispersed twin-screw extruder 10 with an aspect ratio of 32 at a uniform speed through the sec...

Embodiment 2~5

[0081] Examples 2 to 5: The mass fraction of the degrading agent needs to be finally determined through multiple tests according to the requirements of the melt index. The specific implementation method is the same as that of Example 1, and the raw materials and proportions are shown in Tables 5-8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com