A Compensation Mechanism with Controllable Deflection and Expansion Radius of Crack Tip Passivation

A compensating mechanism and expanding radius technology, applied in storage devices, metal processing equipment, feeding devices, etc., can solve the problems that the loading force cannot effectively regulate the deflection of the blanking end of the pipe, and the change of the passivation radius of the crack tip is uncontrollable. Reduce friction and achieve the effect of controlled changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

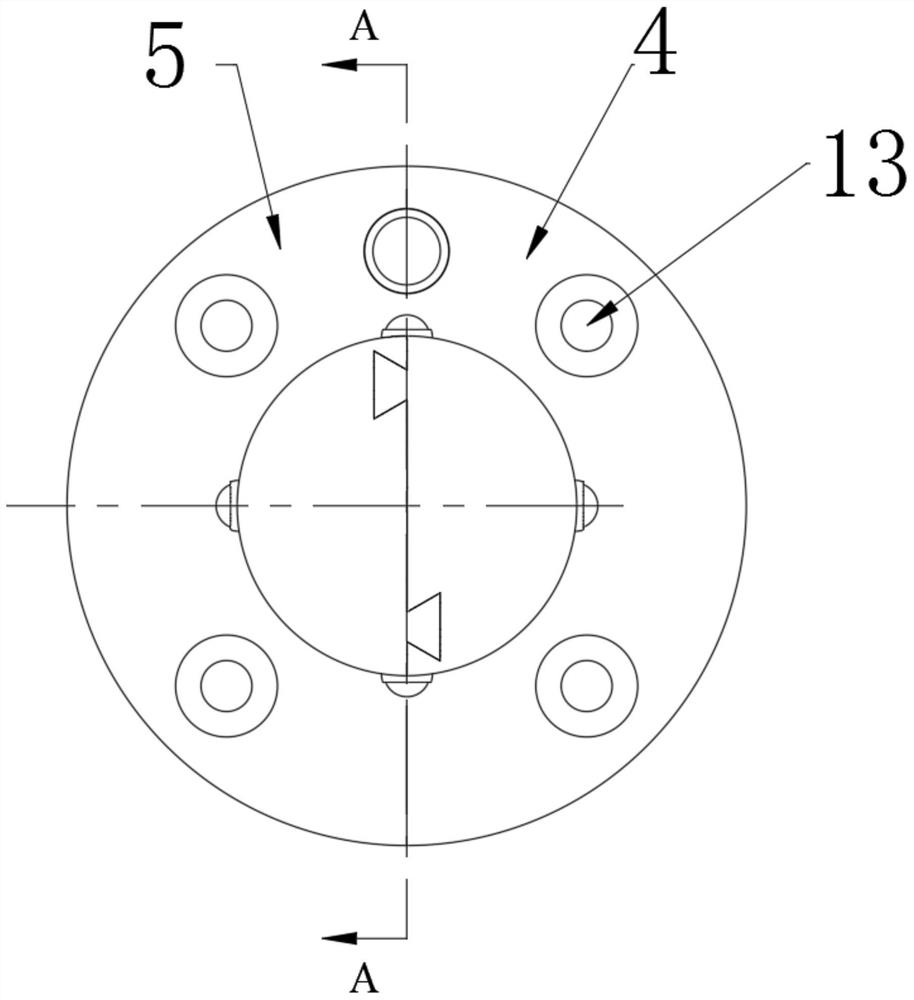

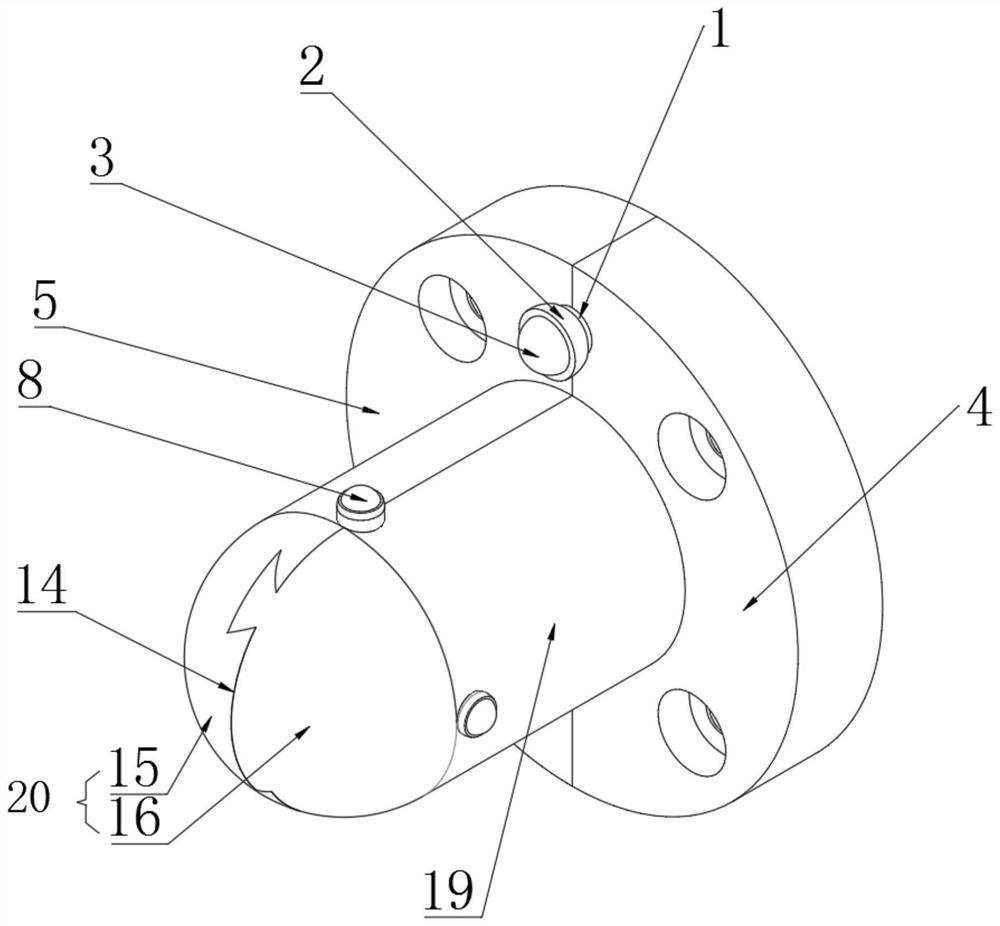

[0042] Embodiment 1, the blanking machine includes a loading transmission shaft 1a, a turntable 2a, a blanking slider 3a, a blanking hammer 4a, a double slide rail 5a, a cutter slider 6a and a slotting knife 7a, and figure 1 It is a schematic diagram of the slotting and blanking of the pipe blanking machine in the prior art, as attached figure 1 shown. Fix one end of the pipe material in the clamping mechanism at the left end, and the other end is cantilevered under the slotting and unloading mechanism. The frequency conversion motor drives the loading transmission shaft 1a to rotate, and at this time, the turntable 2a matched with the loading transmission shaft 1a also follows it. The synchronous rotation makes the integrated linkage device for pipe material slotting and unloading fixed on the turntable 2a rotate synchronously. When slotting, the thrust loading cylinder pushes the loading slide to drive the turntable 2a to move backward, and the cutter slider 6a drives the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com