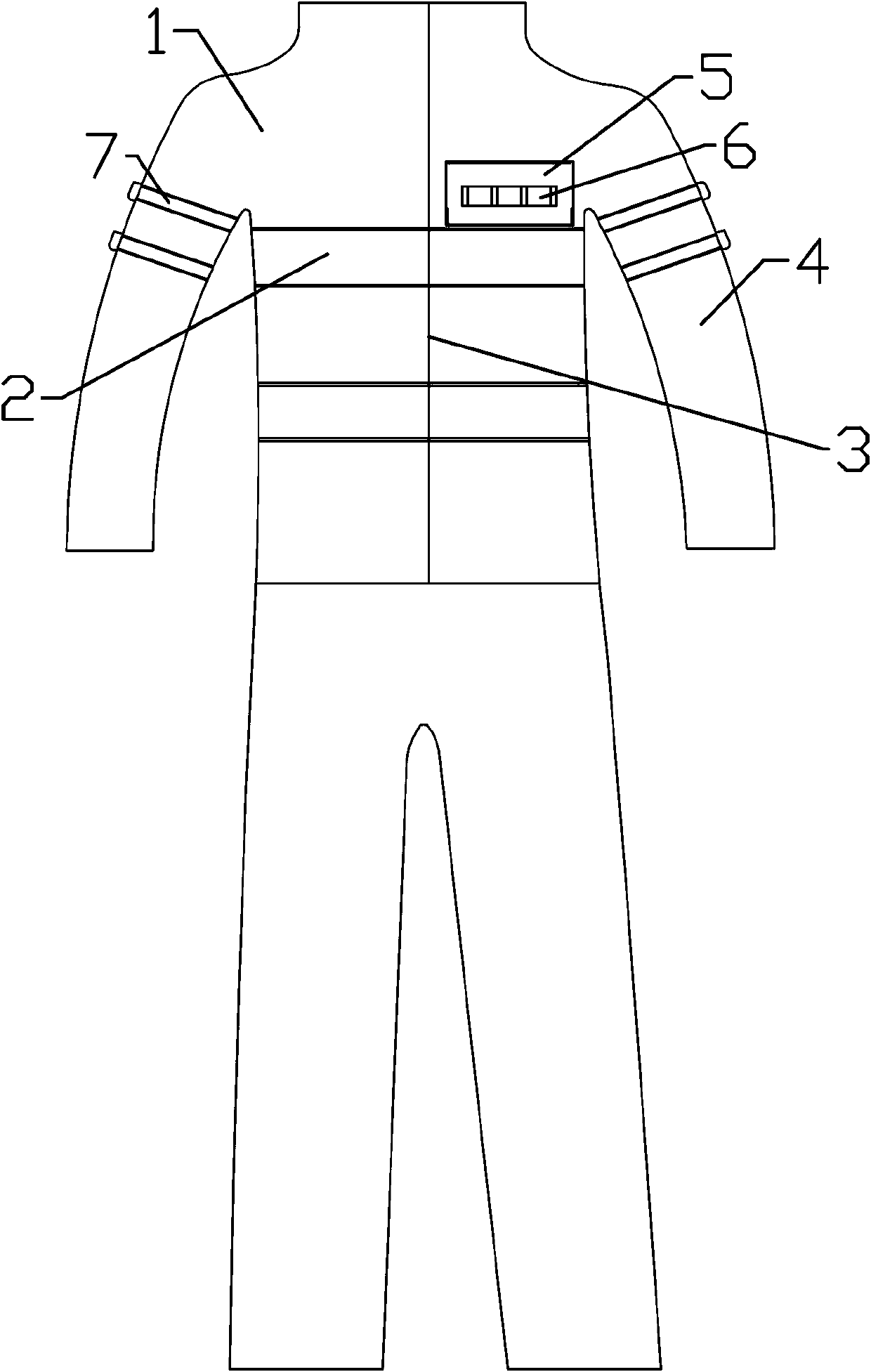

Manufacturing process of color-changeable warning protective clothing

A manufacturing process and protective clothing technology, applied in the field of protective clothing, can solve the problems of increased collision points of protective clothing, affecting the operation of on-duty personnel, poor human body protection performance, etc., to improve warning performance, improve traffic safety performance, and good UV protection performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

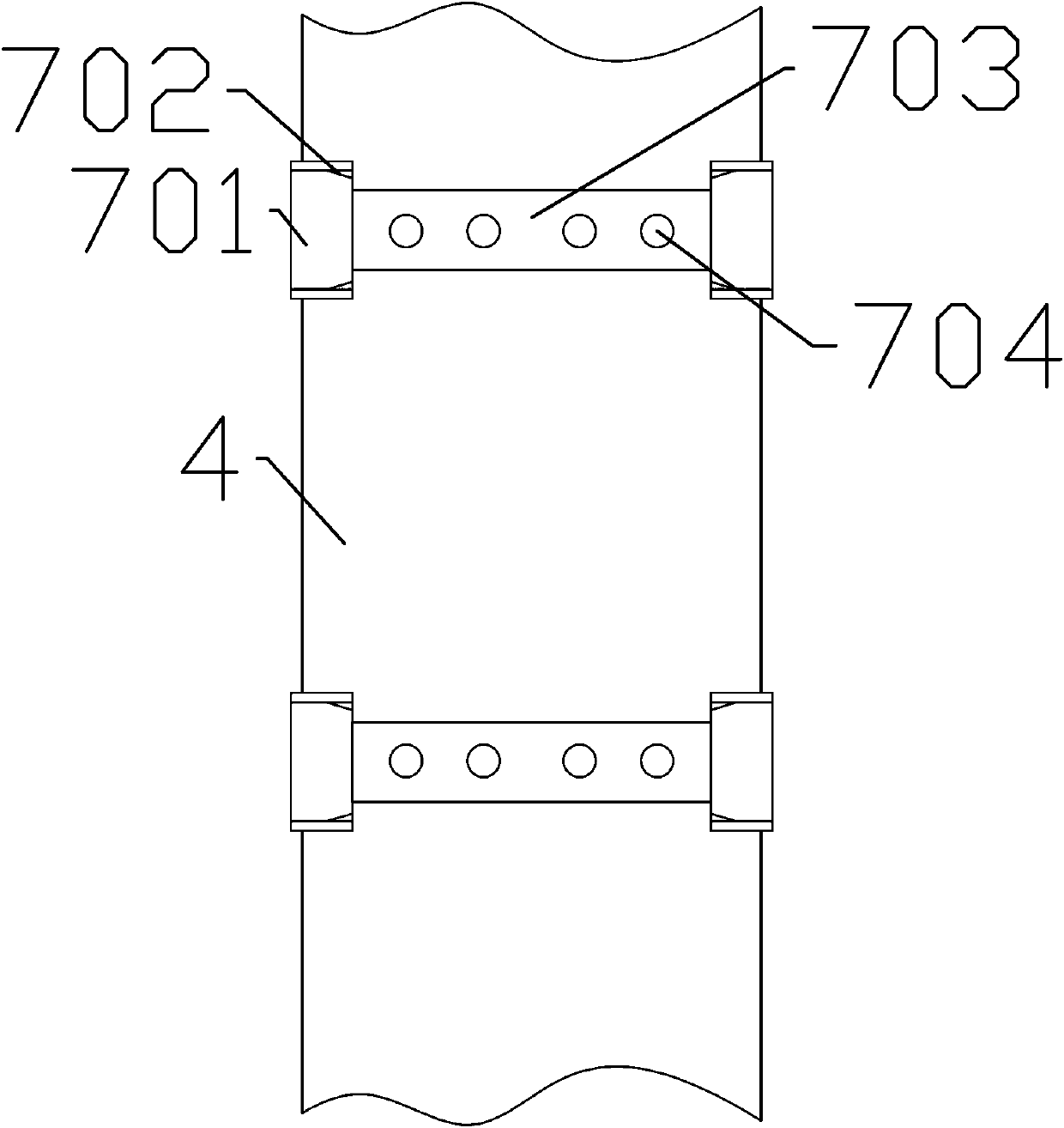

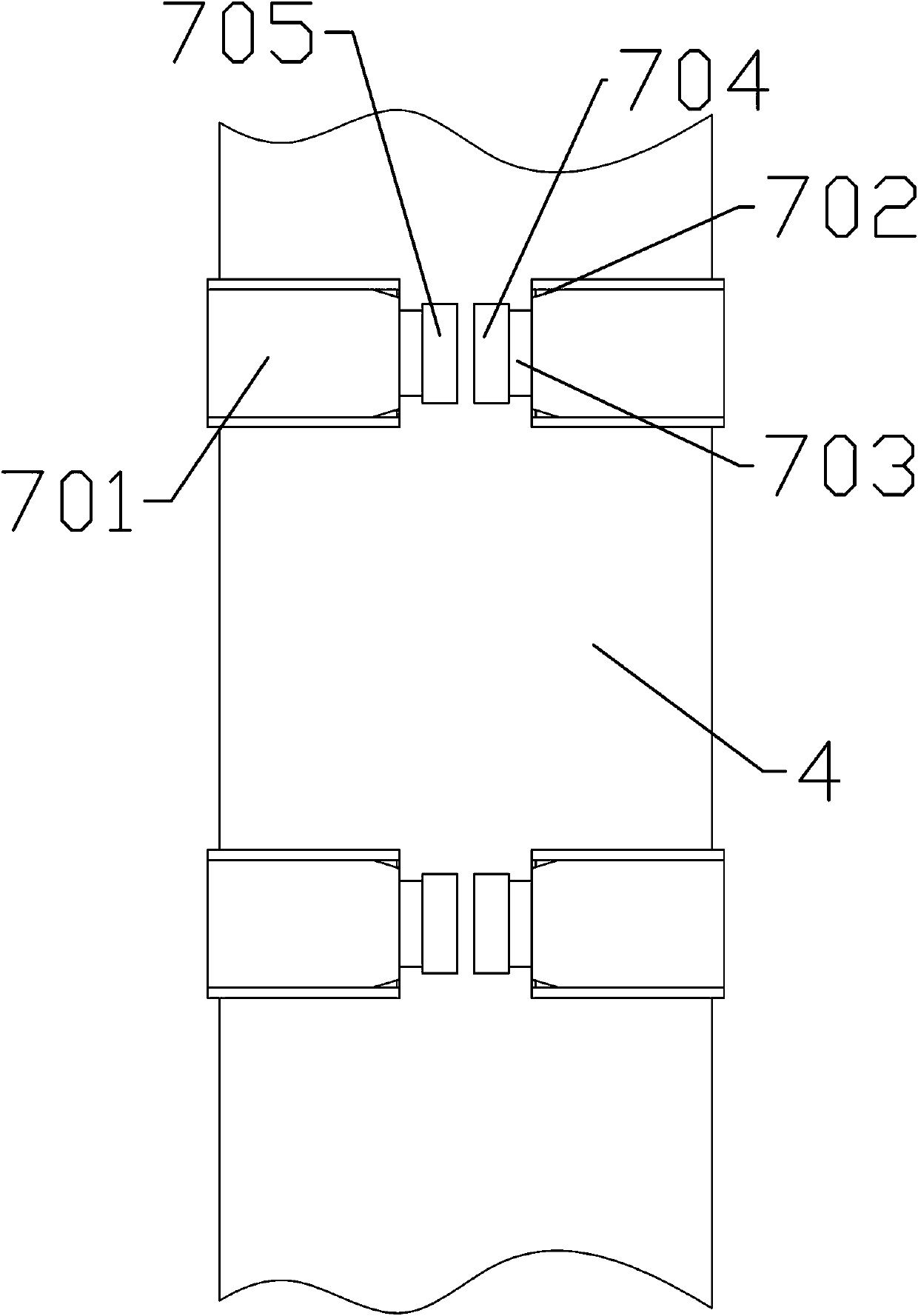

[0032] A manufacturing process of color-changing warning protective clothing, comprising the following steps:

[0033] Step 1: Take the polypropylene fabric 101 and the pure cotton fabric 102, heat-compress the polypropylene fabric and the pure cotton fabric to obtain a unidirectional moisture-wicking fabric;

[0034] Step 2, blending polyester fiber and cotton fiber with a blending ratio of 4-6:5 to obtain an anti-ultraviolet breathable fabric 103;

[0035] Step 3, take the waterproof, oil-proof and anti-fouling fabric 104, compound the unidirectional moisture-wicking fabric, UV-proof and breathable fabric, waterproof, oil-proof and stain-proof fabric, wherein the UV-proof and breathable fabric is located between the unidirectional moisture-wicking fabric, waterproof, oil-proof and stain-proof fabric , the anti-ultraviolet breathable fabric is adjacent to the pure cotton fabric, bleached, and sprayed with photochromic powder on the surface of the waterproof, oil-proof and ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com