Job-site tool

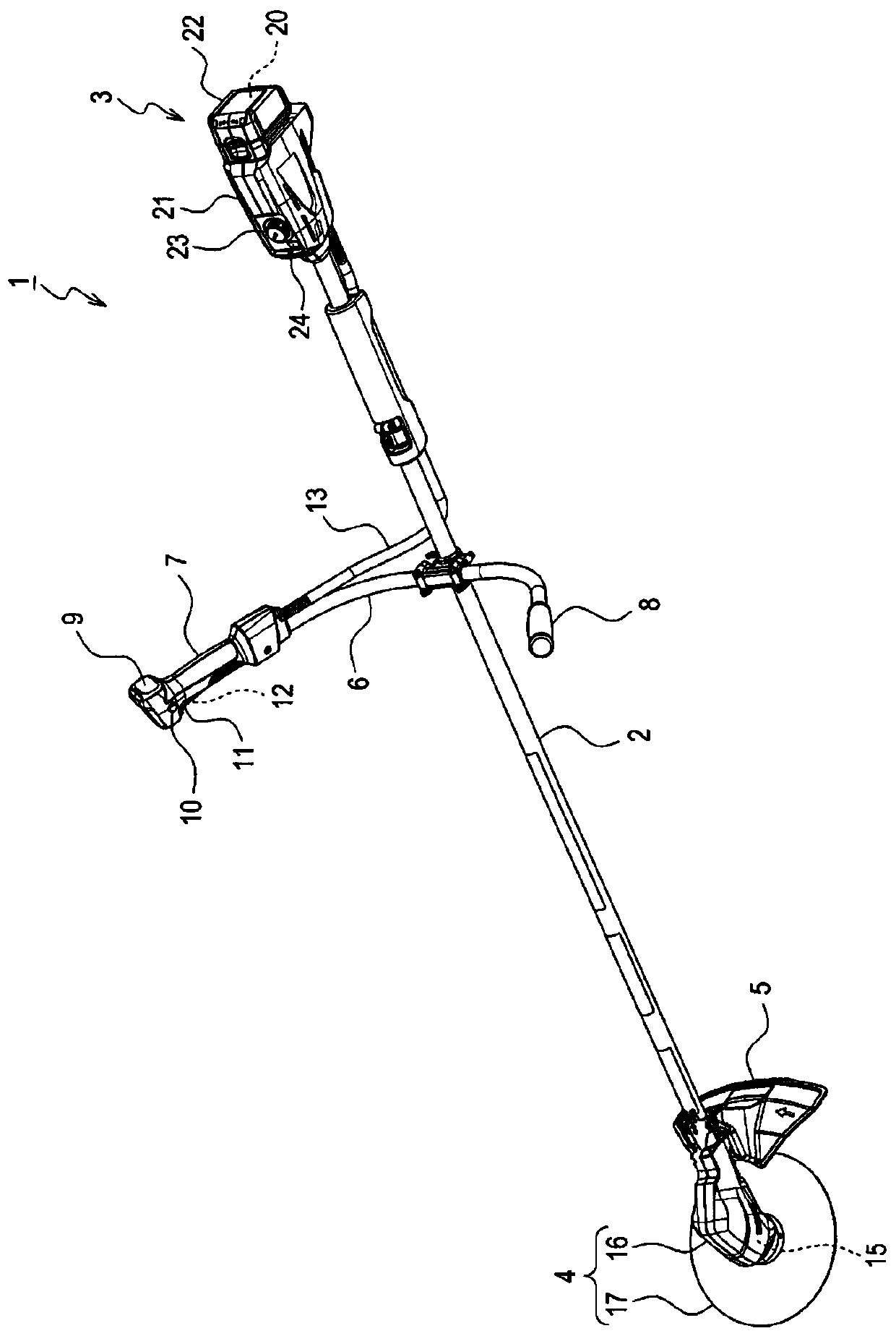

A technology for working machines and lenses, applied in agricultural machinery and implements, agriculture, harvesters, etc., can solve the problems of lack of waterproof performance, LED failure, etc., and achieve the effect of ensuring waterproof performance, inhibiting immersion, and excellent waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0091] According to the first embodiment described above, the following effects can be obtained.

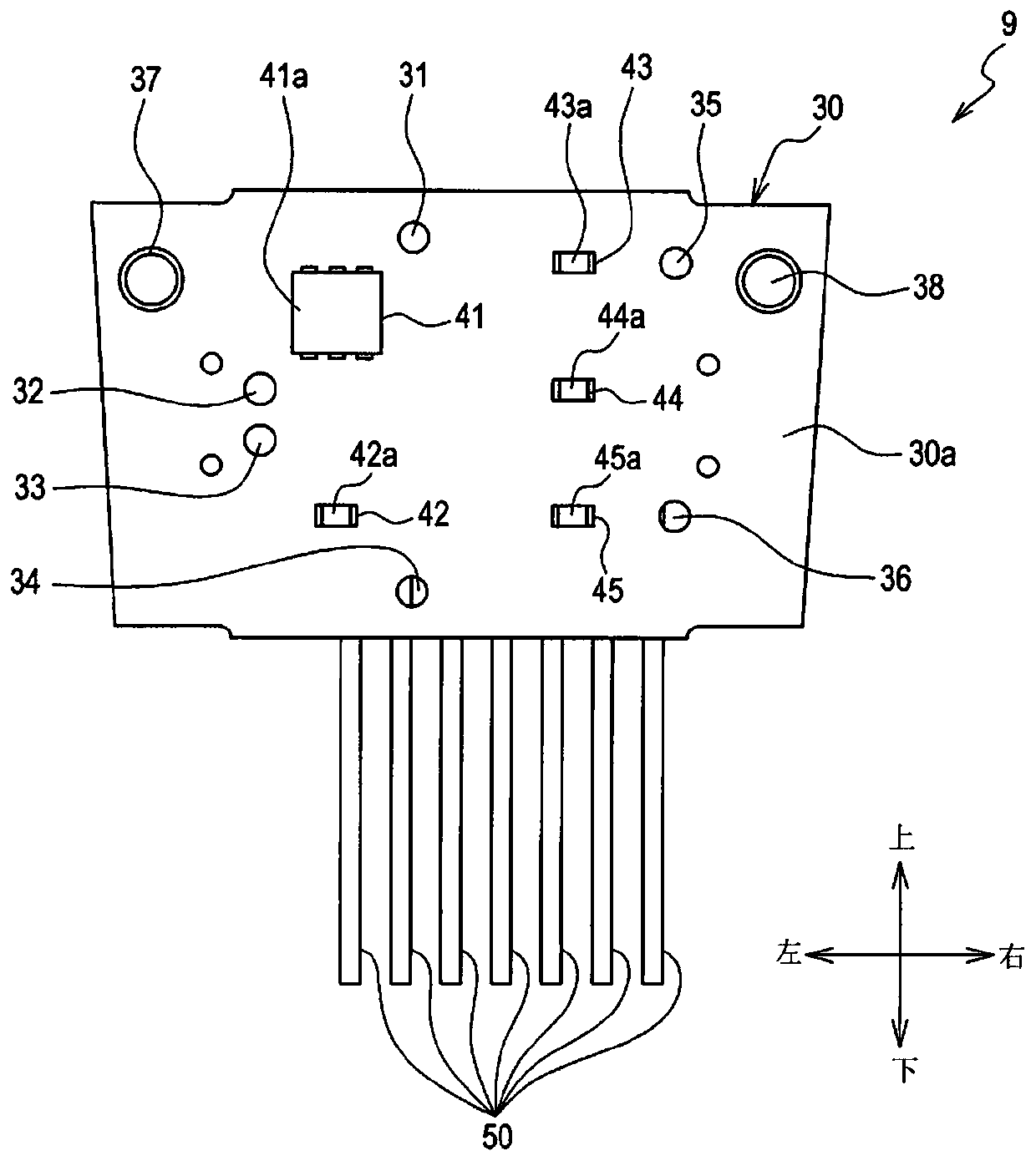

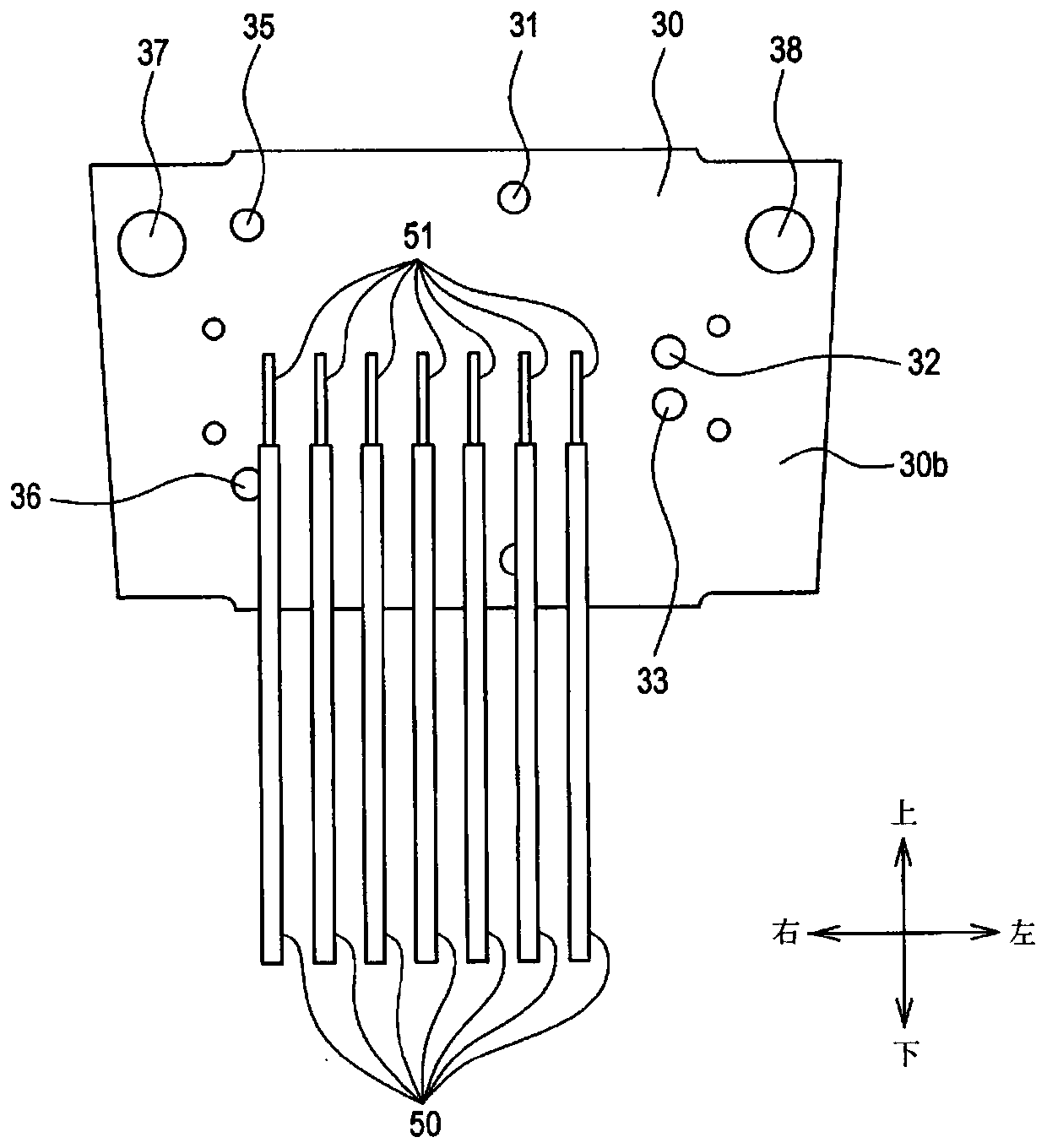

[0092] (1) The LEDs 41 to 45 provided on the substrate 30 are covered with the large lens 60 and the small lens 71 . Furthermore, the surroundings of the large lens 60 and the small lens 71 are covered with a resin member 80 and fixed to the substrate 30 . Therefore, the large lens 60 and the small lens 71 are less likely to fall off from the substrate 30 . In addition, the large lens 60 and the small lens 71 are more wear-resistant than plastic sheets. Furthermore, the lead wire 50 is also covered with the resin member 80 . Therefore, the infiltration of liquid into LED41-45 and the lead wire 50 can be suppressed, and the outstanding waterproof performance of the display part 9 can be realizable.

[0093] (2) LED41,42 is respectively covered with the large lens 60, and LED43-45 is respectively covered with the small lens 71. Thereby, the waterproof performance for each of LE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com