A green onion combine harvester and method

A technology for combine harvesters and scallions, applied in the direction of digging harvesters, harvesters, excavators, etc., can solve the problems of low integration, achieve high-efficiency harvesting, meet drag reduction and crushing performance, and the harvesting process is simple and efficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

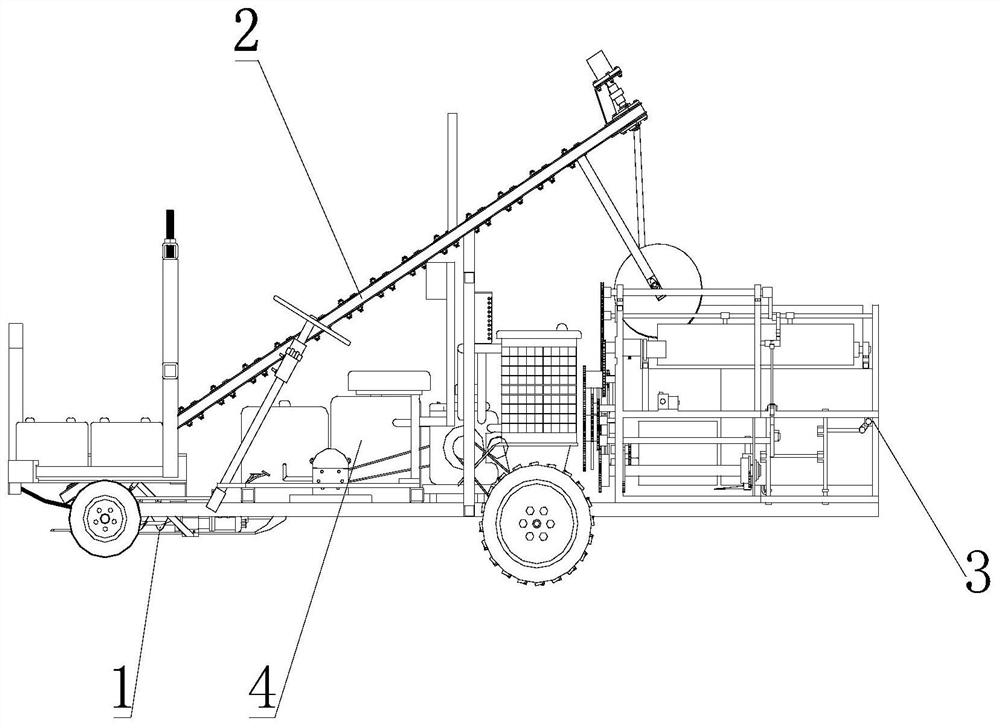

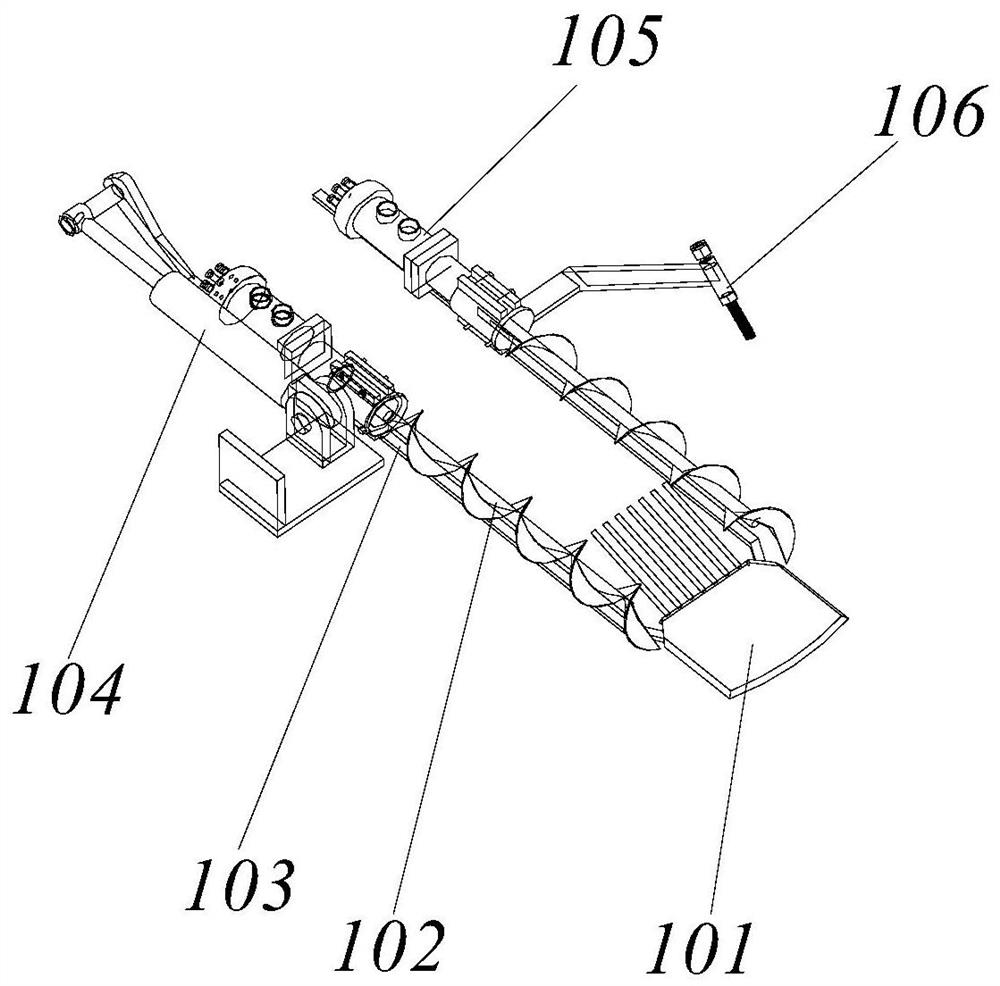

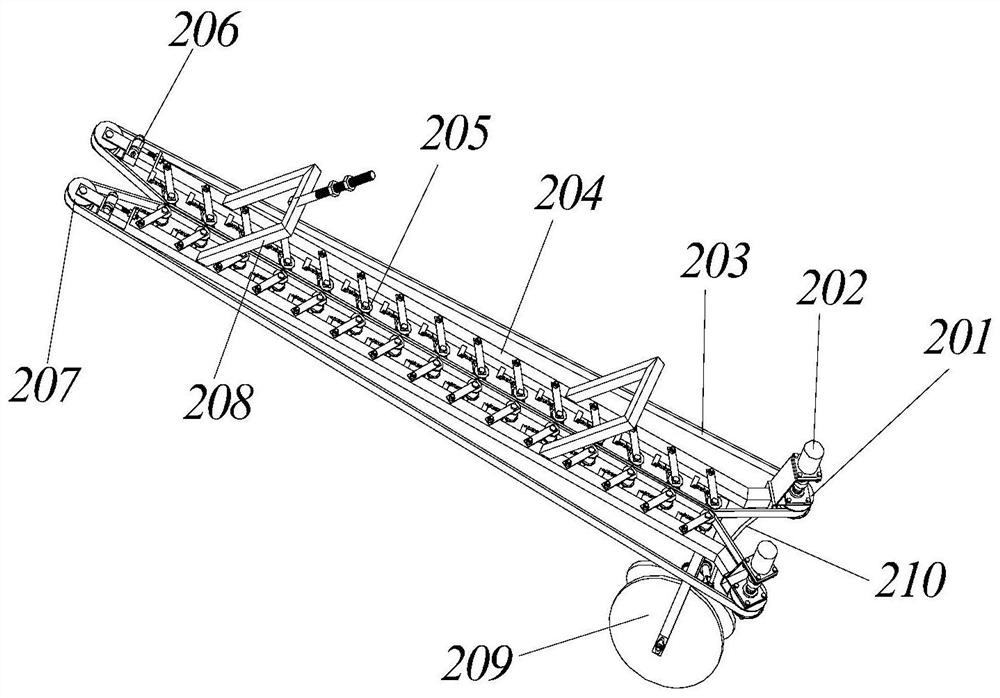

[0041] In order to solve the technical problems in the background technology, this disclosure discloses a scallion combine harvester, such as figure 1 As shown, a scallion combine harvester includes a chassis frame 4, a side of the chassis frame 4 is provided with a double auger combination excavation device 1, and the rear end of the double auger combination excavation device 1 is connected to the chassis frame 4 through a hydraulic cylinder. The lifting and digging of the excavating device are adjusted through the expansion and contraction of the hydraulic cylinder. The double-sided symmetrical flexible clamping and conveying device 2 is installed obliquely above the double-auger combined excavating device 1, and the double-sided symmetrical flexible clamping and conveying device 2 passes through the The square tube welded on the chassis frame 4 is fixed on the chassis frame 4, and the front end of the double-sided symmetrical flexible clamping and conveying device 2 is match...

Embodiment 2

[0049] This embodiment discloses a method for using a scallion combine harvester, and the specific steps are as follows:

[0050] 1) The green onion combine harvester advances along the ridge, and the double auger combined excavation device enters the soil to loosen the soil for the green onion;

[0051] 2) The scallions excavated by the double auger combined excavation device are clamped by the double-sided symmetrical flexible clamping and conveying device, and are transported obliquely upward;

[0052] 3) The double-sided symmetrical flexible clamping and conveying device transports the green onions to the continuous quantitative collection and bundling device, and the harvested green onions are bundled and collected by the continuous quantitative collection and bundling device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com