A packaging device for silicon microphone chips

A technology for packaging equipment and silicon microphones, applied in sensors, electrostatic transducers, microphones, electrical components, etc., can solve the problems of increasing product error rate, low production efficiency, and mismatching production efficiency, reducing labor intensity, The effect of reducing site waste and compact installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

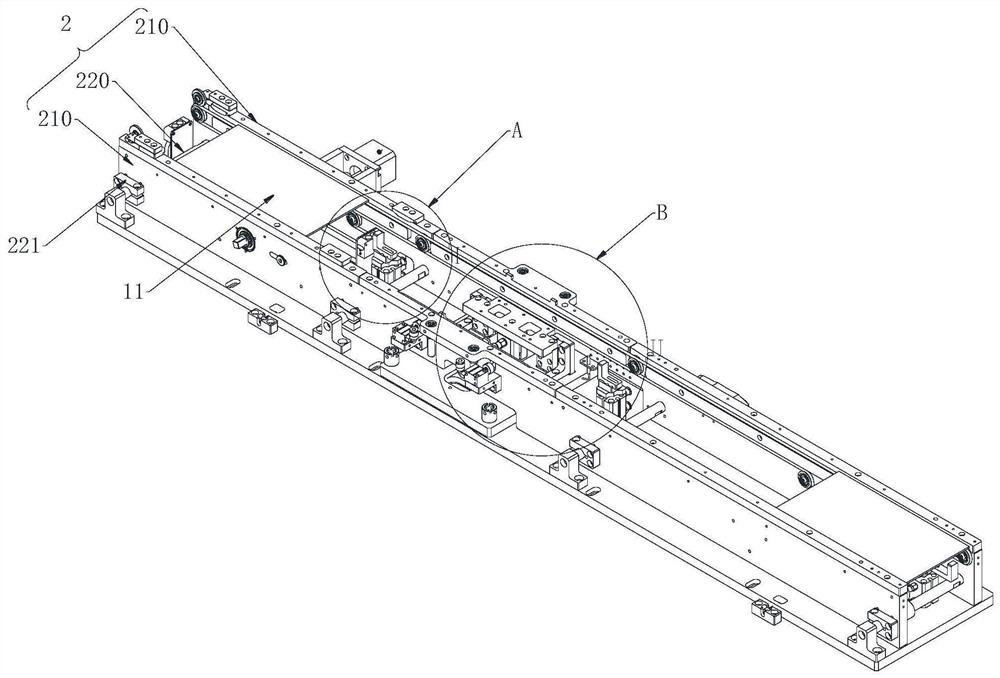

[0049] The packaging equipment for silicon microphone chips of the present invention includes a workbench 1, a first flow channel 2 and a second flow channel 240 are arranged side by side on the upper end of the workbench 1, and a drying oven is arranged between the first flow channel 2 and the second flow channel 240. The baking device 12, the workbench 1 is provided with a feeding device 9, a dispensing device 4 and a first manipulator 5 located above the first flow channel 2 and arranged in sequence along the conveying direction of the first flow channel 2, and the workbench 1 is also provided with a The second manipulator 6, the tin drawing device 7, the AOI detection device 8 and the unloading device 10 arranged in sequence above the second flow channel 240 along the conveying direction of the second flow channel 240; the first flow channel 2 and the second flow channel 240 both include The connecting column 220 and the two limiting plates 210 arranged side by side, the tw...

Embodiment 2

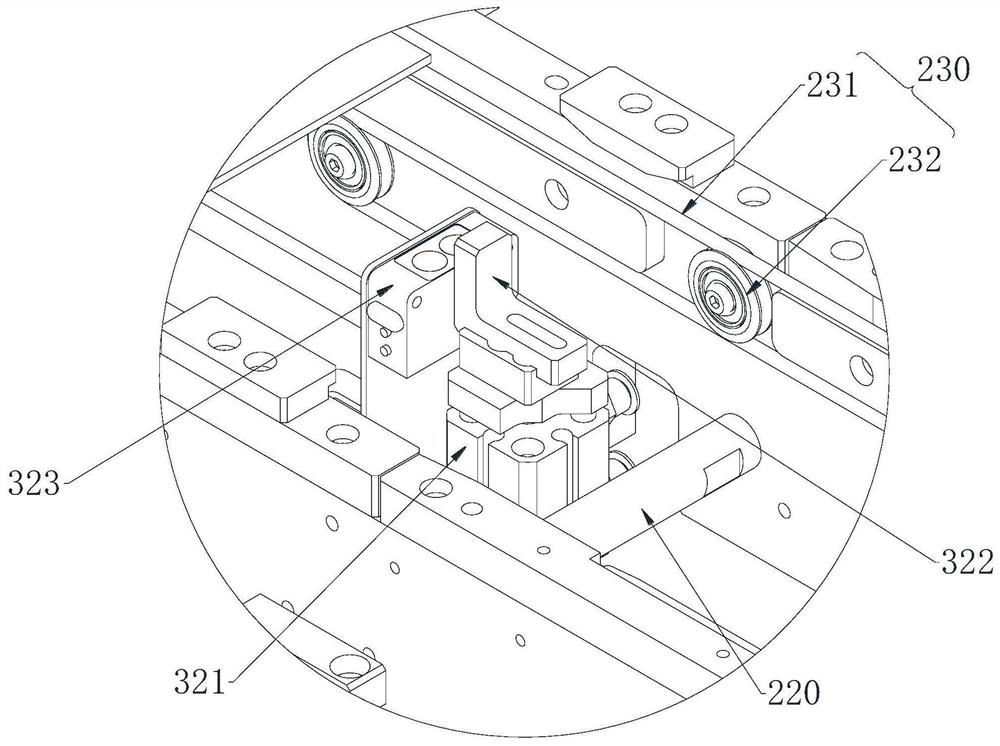

[0052] The present embodiment is further optimized on the basis of Embodiment 1 as follows: the belt assembly 230 includes a belt 231, a pulley 232 and a drive motor, a plurality of pulleys 232 are rotationally connected with the inner sidewall of the limiting plate 210, and the belt 231 is sleeved on On the periphery of all the pulleys 232 on the same side, the drive shaft of the drive motor passes through the limiting plate 210 and is connected to the pulleys 232 with each other.

[0053] After adopting the above-mentioned technical solution: the two limiting plates 210 are vertically arranged, and the two limiting plates 210 are fixedly connected through the connecting column 220, and a space for accommodating the movement of the chip is formed between the two limiting plates 210, and the two limiting plates 210 are connected vertically. A belt assembly 230 is arranged on the opposite inner side of the limiting plate 210. The belt assembly 230 is divided into two groups. The...

Embodiment 3

[0055]This embodiment is further optimized on the basis of Embodiment 1 as follows: the clamping unit 310 includes a horizontal bottom plate 311, a push plate 315, a load-bearing platform 313, a push-pull cylinder 312 and a first jacking cylinder 314, the horizontal The bottom plate 311 is located at the upper end of the workbench 1, the first jacking cylinder 314 is arranged on the upper end of the horizontal bottom plate 311, the upper end of the first jacking cylinder 314 is connected to the load-bearing platform 313, and the horizontal bottom plate 311 is also provided with a plurality of Horizontal adjustment bolt 316, the push-pull cylinder 312 is connected with the outer side wall of the limit plate 210, the push-pull cylinder 312 is connected with the push plate 315 after penetrating the limit plate 210, and the push plate 315 is located on the outside of the belt assembly 230 . The limiting assembly 320 includes a stopper 322 and a second jacking cylinder 321, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com