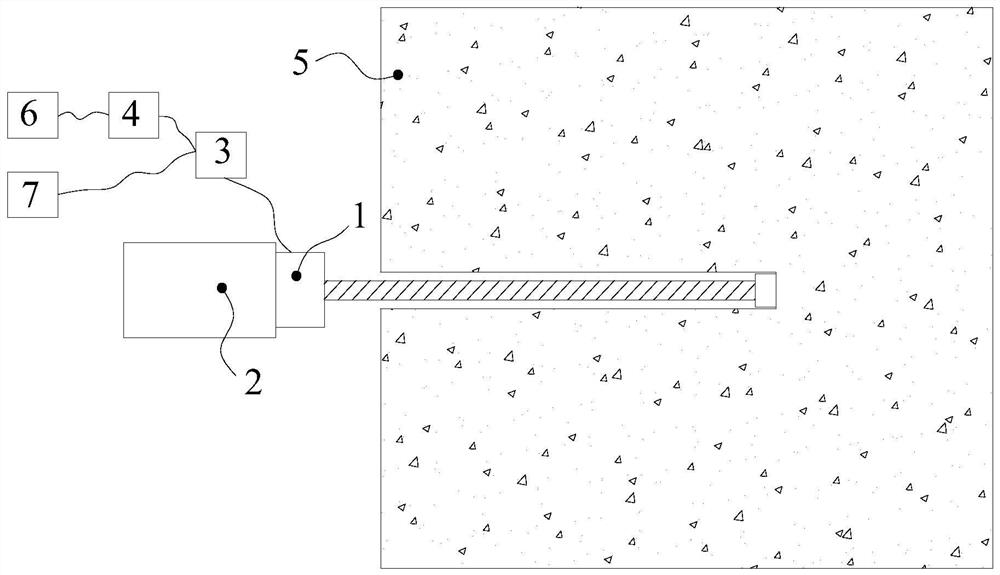

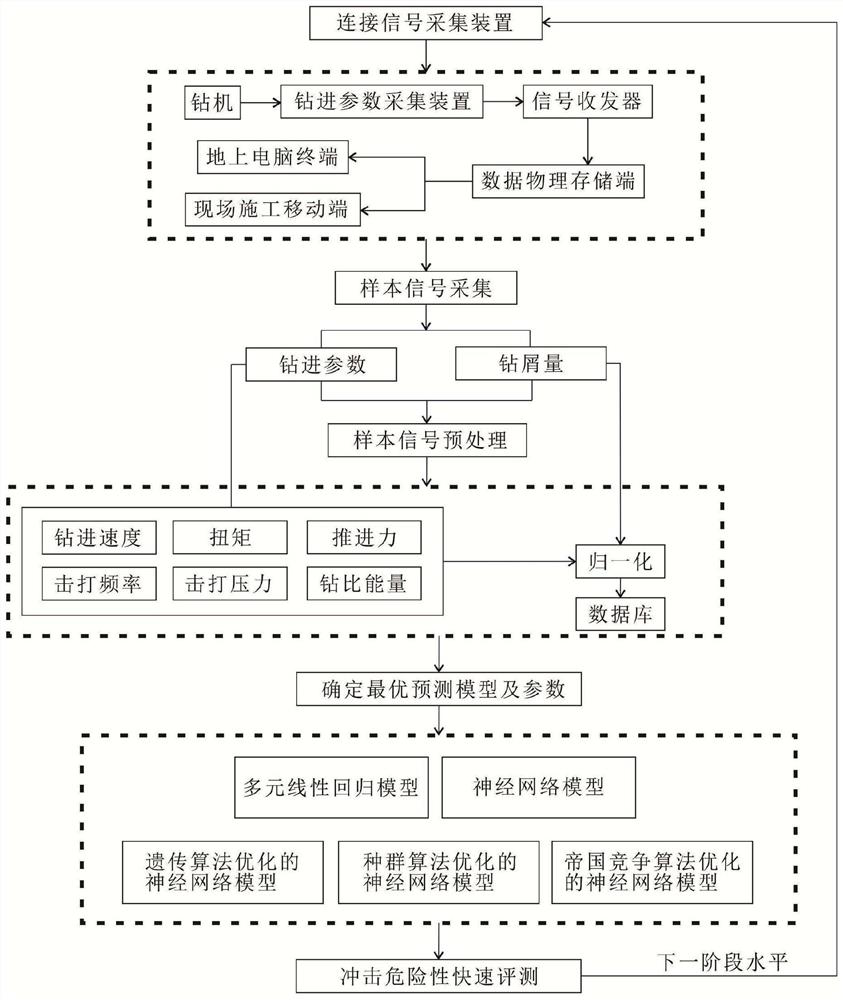

Real-time assessment method of coal seam impact hazard based on measurement-while-drilling technology

A measurement-while-drilling, dangerous technology, applied in measurement, neural learning methods, earthwork drilling and mining, etc., can solve problems such as reducing the efficiency of rock burst prediction, increasing the difficulty of obtaining sample data, and large errors in processing results, so as to reduce the evaluation cost, guarantee of objective accuracy, effect of guarantee of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to more concisely describe the overall operation process of the present invention, a mine-300m level mining stage is used as an example, and a layer of coal (3 # coal) is carried out in this level, and the coal-coal impact tendency identification, identification results In order to have a tendency of impact, the horizontal mining stage design plan has a total of 10 back to 20 back and 20 cartridges. It needs to perform impact risk comprehensive assessment for all working surface mining and excavation, and is weak for comprehensive assessment. The working surface of the medium and strong impact level needs to perform impact ground pressure during mining or excavation. In the process of mining or digging, the method of efficient and accurately predicting the impact ground pressure is predicted. In order to make it easy to describe, the working surfaces in each of the mining sequentials are sequentially referred to as the first working surface, the second working surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com