Alkaline cleaning agent for food factory pipeline as well as preparation method and application thereof

A cleaning agent and pipeline technology, applied in the field of cleaning agents, can solve the problems of not being able to adapt to beverage dirt, limited dissolution speed of dirt, and poor effect, and achieve the effects of preventing deposition, good combination, and reducing cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further limited below in conjunction with specific embodiments, but the scope of protection is not limited to the description.

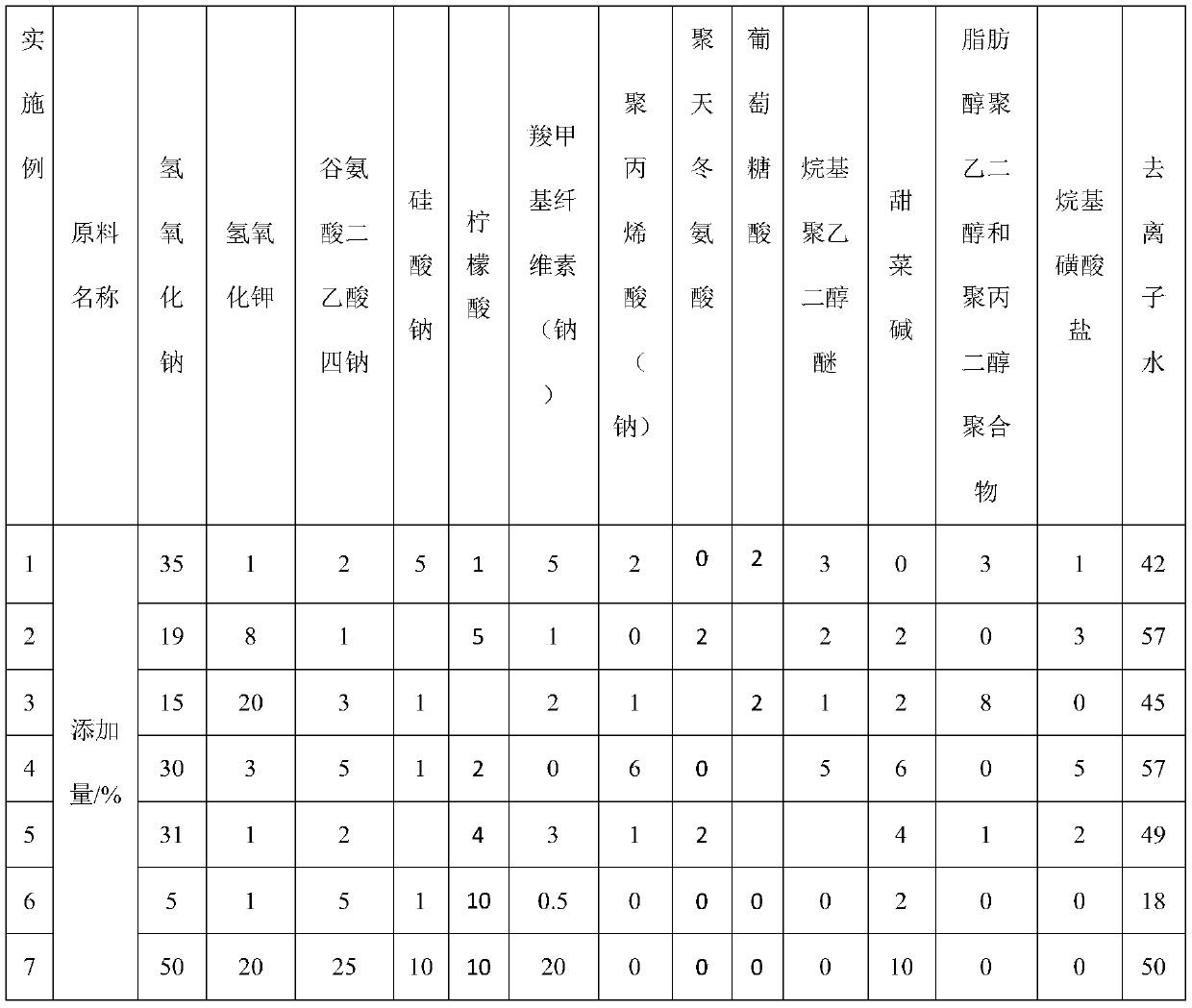

[0018] The formulations of Examples 1-7 are as follows:

[0019]

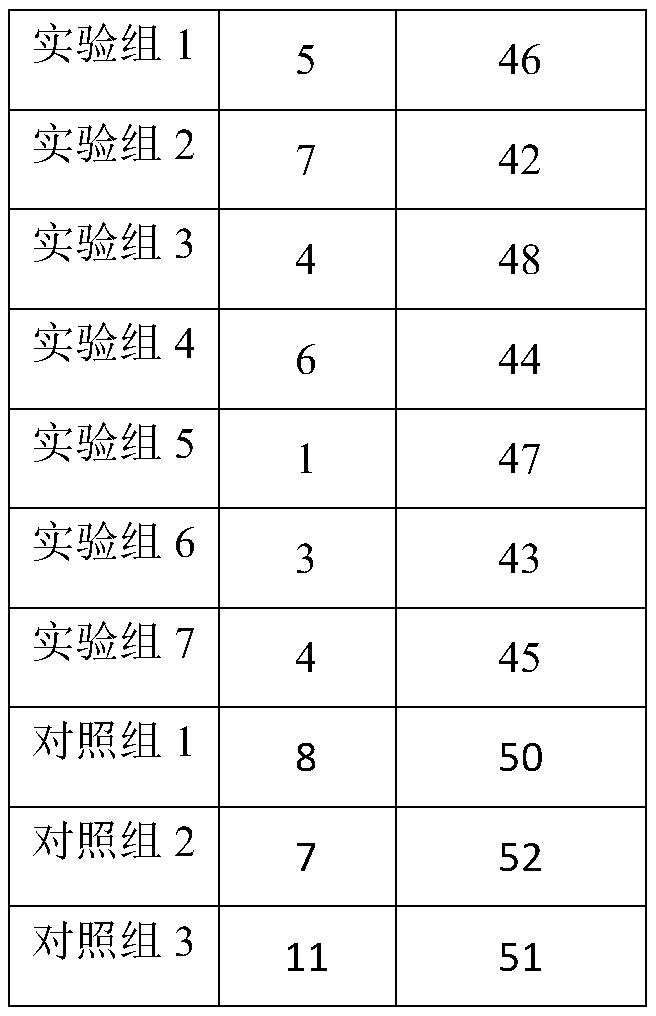

[0020] The products of the present invention of the above embodiments 1-7 were prepared into a dilution of 1% and recorded as experimental groups 1-7 respectively; the phosphorus-free pipeline cleaning agent produced by Jinan Meiwang Chemical Co., Ltd. was used as control group 1; Shanghai Chen was used as the control group. The phosphorus-free pipe cleaning agent produced by Ernest Instruments Co., Ltd. is the control group 2; the phosphorus-free pipe cleaning agent produced by Jiangsu Dalt Water Treatment Engineering Co., Ltd. is the control group 3; the experimental group and the control group cleaning agent are completely wetted by 1 square centimeter The time required for the canvas piece is recorded as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com