Air pumping system

A suction system, suction system technology, applied in textiles and papermaking, conveying filamentous materials, joint devices, etc., can solve problems such as reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

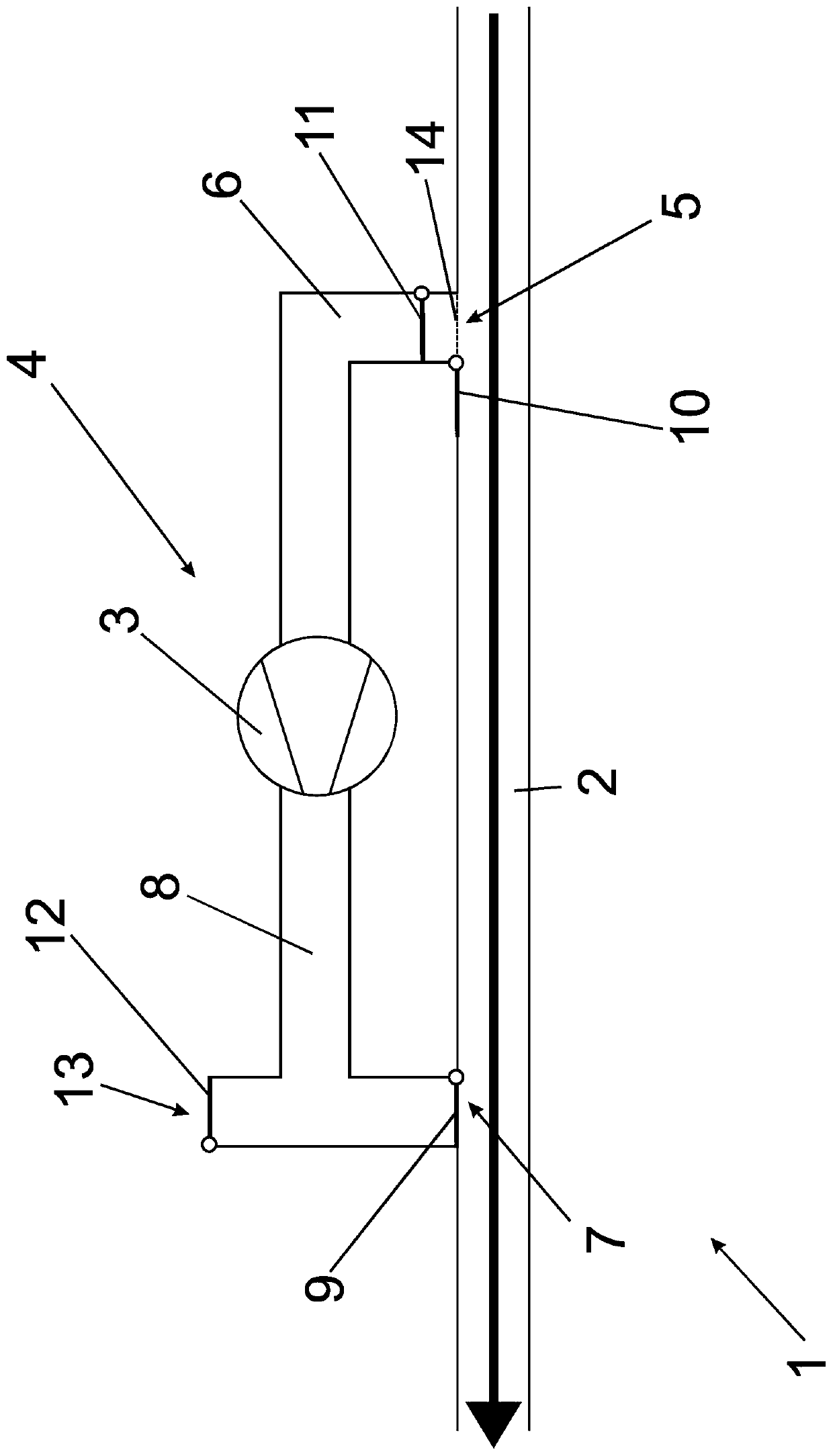

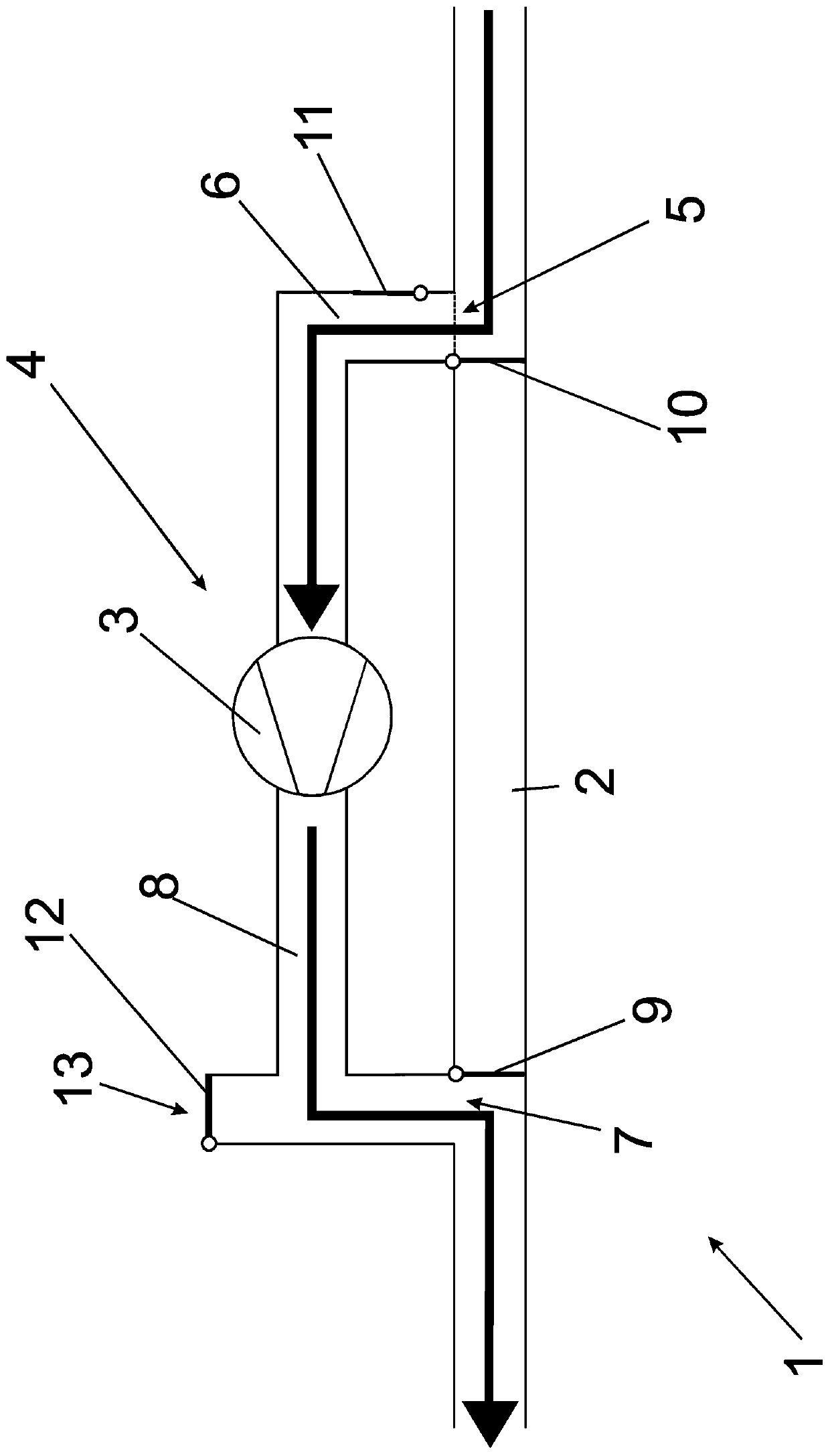

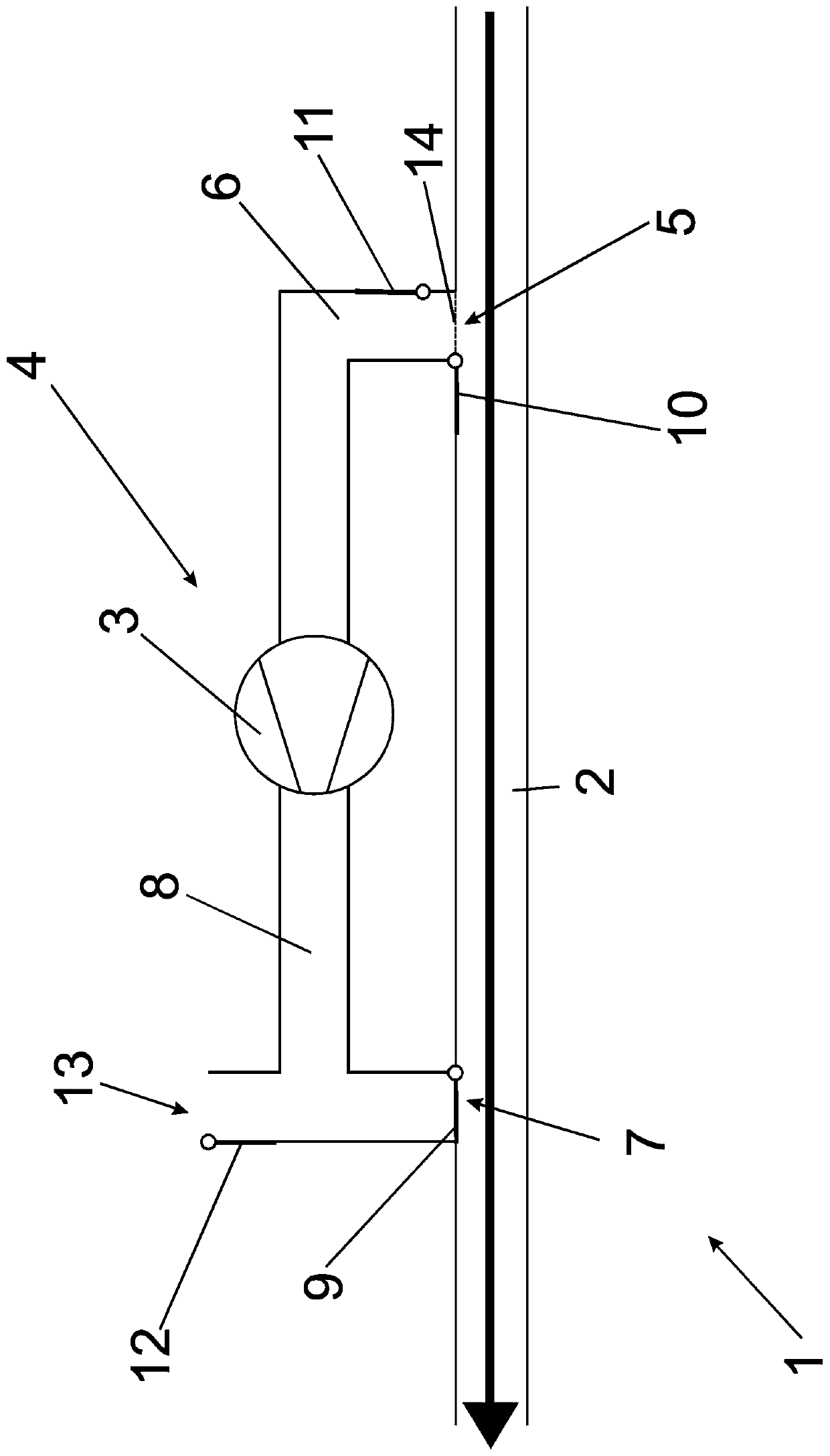

[0045] in such as Figure 1 to Figure 3 In the shown suction system 1, an additional suction system 4 is connected to the machine suction channel 2 via an inlet channel 6 and an outlet channel 8, whereby the stations of the textile machine not shown here are connected to supply all stations central suction channel. In order to connect the additional suction system 4 to the machine suction channel 2, an inlet 5 and an outlet 7 are provided at the machine suction channel 2, the inlet channel 6 or the outlet channel 8 being connected to the inlet or the outlet respectively. At their end opposite the inlet 5 or outlet 7 , the inlet channel 6 as well as the outlet channel 8 are connected to an additional source of negative pressure in the form of a fan 3 .

[0046] in such as figure 1 In normal operation shown, without switching on the additional suction system 4, the second closing element 10 is arranged in the open position for opening the suction channel 2 of the machine, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com