Composite processing machine

A technology for compound processing and rotating tools, applied in metal processing mechanical parts, metal processing equipment, tool holders, etc., can solve the problems of complex structure and control, poor mass productivity, and inability to rotate, and achieves cheap and compact structure, practicality The effect of excellent, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

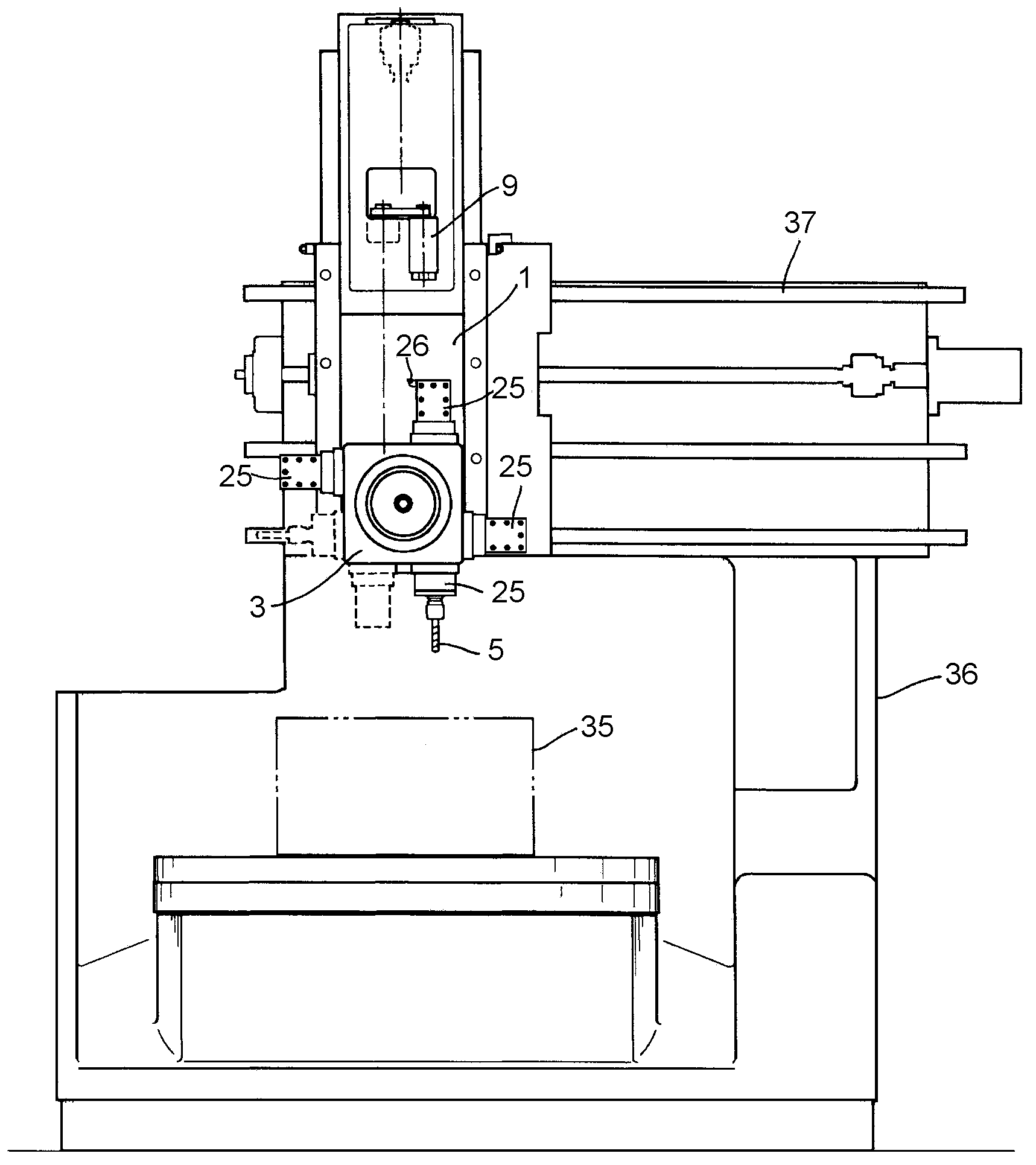

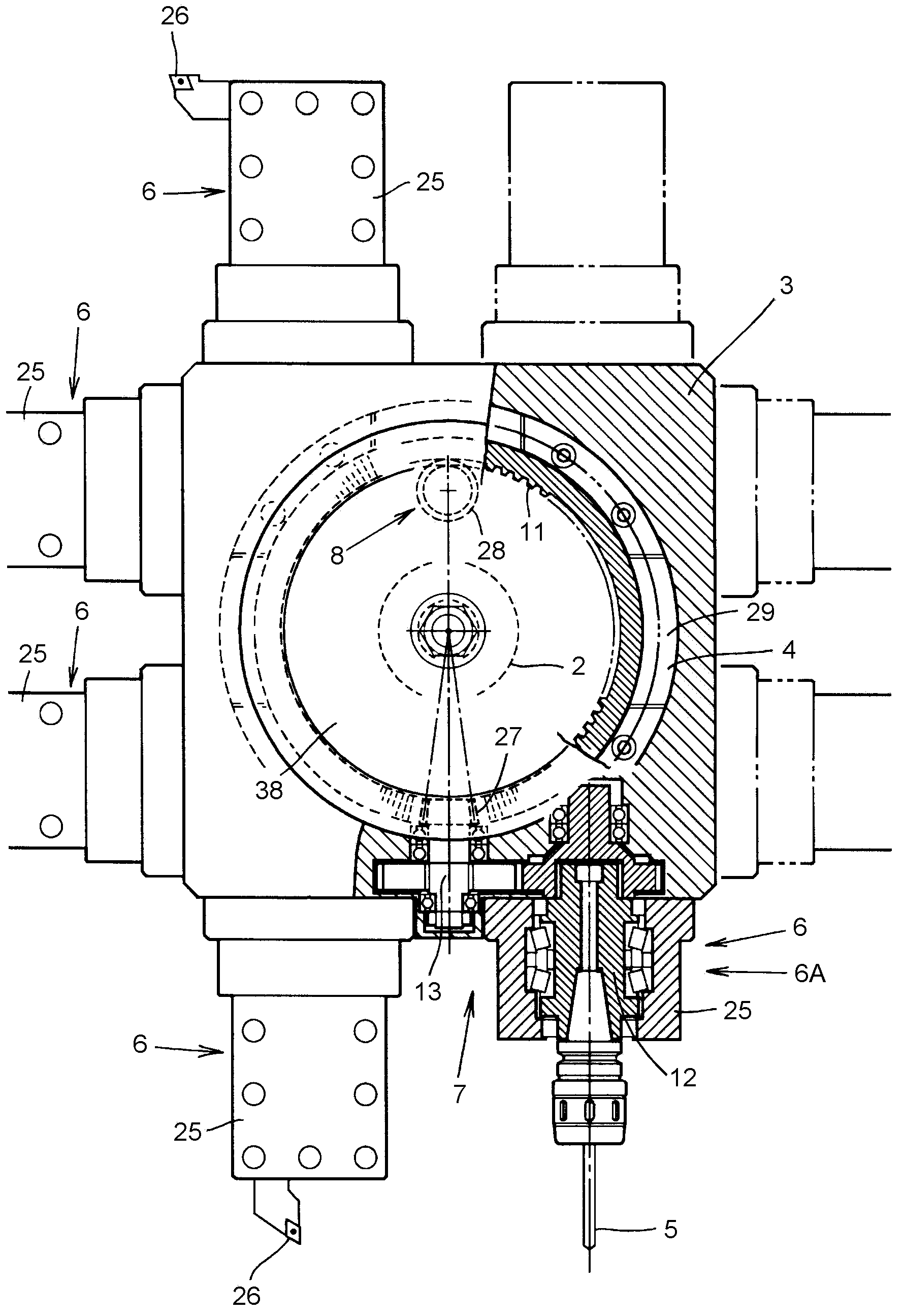

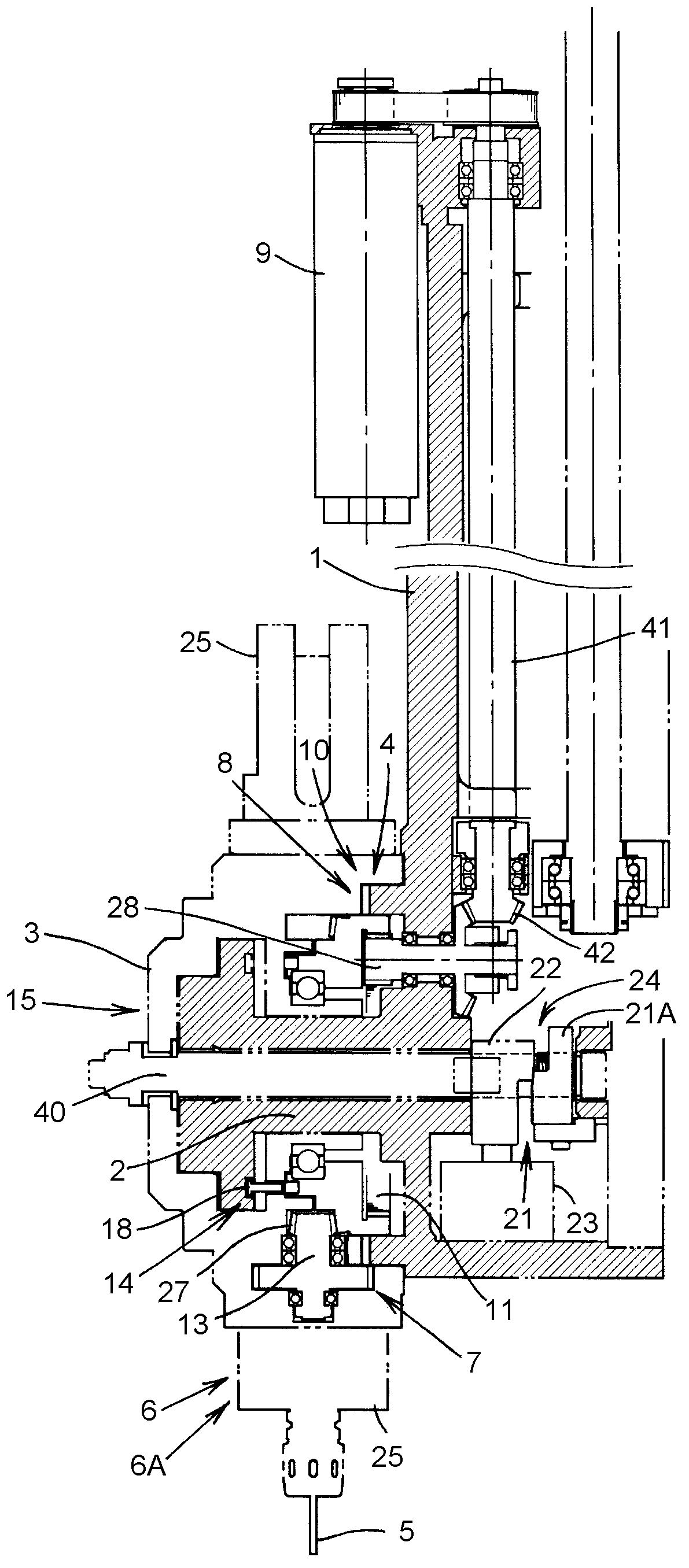

[0078] Specific embodiments of the present invention will be described based on the drawings.

[0079] In this embodiment, the present invention is applied to automatic rotary turret devices of machine tools such as vertical lathes, such as figure 1 As shown, in the automatic rotary turret device, the turret 3 is controlled to move in the XYZ direction relative to the workpiece 35 via the column 36, the transverse guide rail 37, and the turret base 1, and tools are provided on each surface of the turret 3. (The cutter 26 and the rotary tool 5 are respectively provided in the holder 25 so as to be replaceable.) For example, if the turret 3 is formed in a square shape, the tool can be switched by indexing at 90 degrees with respect to the turret base 1 .

[0080] Specifically, as has been described in detail in the existing example, the basic structure of the turret device of this embodiment is: a rotary shaft part 2 is provided on the turret base 1, and the rotary shaft part 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com