ejector

A technology of injectors and actuators, which is applied in the direction of fuel injection devices, special fuel injection devices, machines/engines, etc. It can solve the problems of easily disturbed actuator movement and easily disturbed fuel volume, and achieves easy installation and less The effect of power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

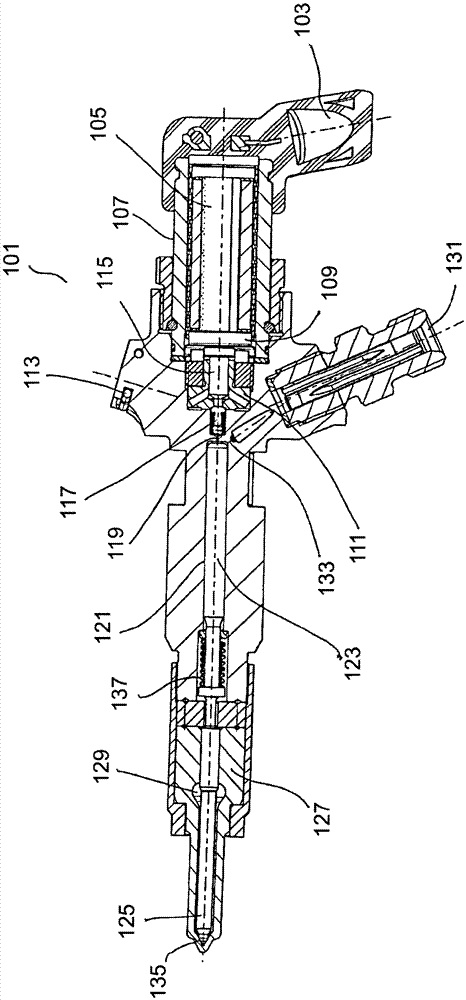

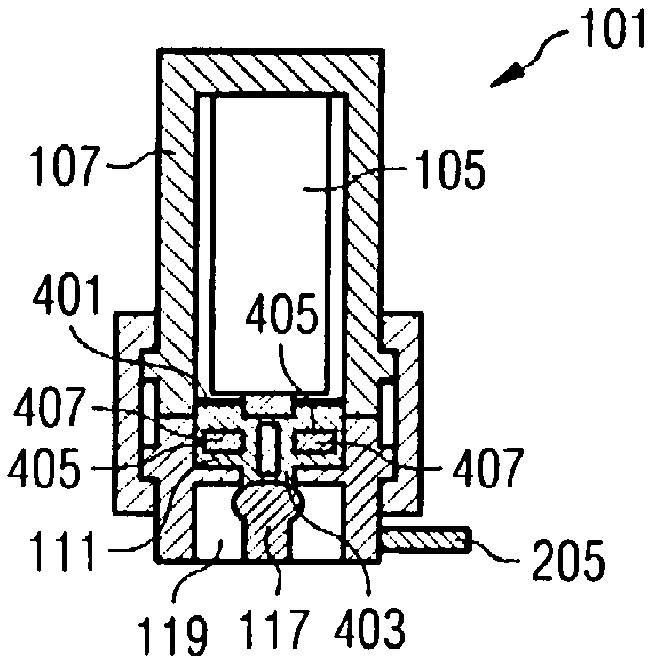

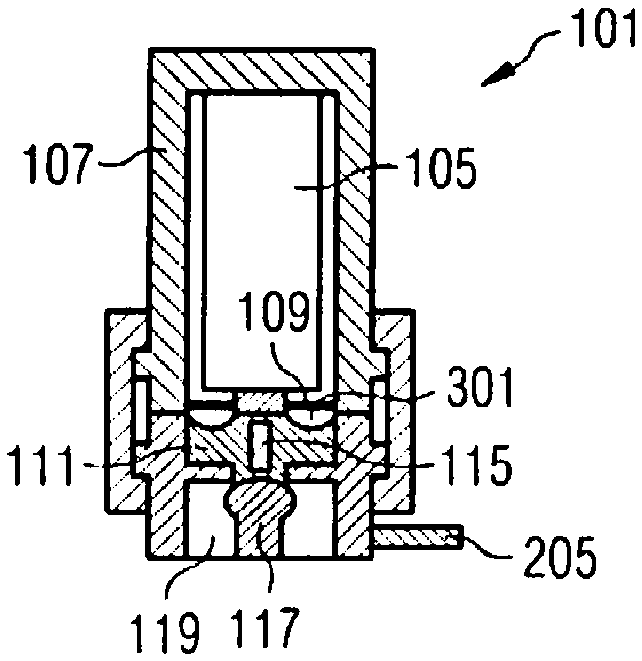

[0027] figure 1 Shown is a cross-sectional view of injector 101 of the present invention. The injector 101 includes an electrical connection 103 for supplying electrical power to a piezoelectric actuator 105 arranged in an actuator housing 107 . The actuator housing 107 is sealed in a fluid-tight manner with respect to the front chamber 111 by means of a double-walled membrane 109 . The antechamber 111 is placed in front of the fluid feedback pipeline (not shown) and is fluidly connected to it, so the antechamber 111 can also be referred to as the antechamber of the fluid feedback pipeline. The injector 101 also has a low pressure connection 113 to which a fluid return line is connected. The double-walled diaphragm 109 will be in image 3 be detailed in.

[0028] An actuator piston 115 is also arranged in the front chamber 111 , so that the extension of the piezo actuator 105 can be transmitted to a control valve 117 . Piezo actuator 105 is thus coupled via actuator pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com