Automatic glue dispensing equipment for LED lamp tube processing

An LED lamp tube and automatic dispensing technology, which is applied to coatings, devices that apply liquid to the surface, etc., can solve problems such as insufficient bonding of the lamp beads, affecting the quality of the lamp strip, and easy deviation of the dispensing position. , to achieve the possible effect of avoiding deviation, good quality and reducing displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

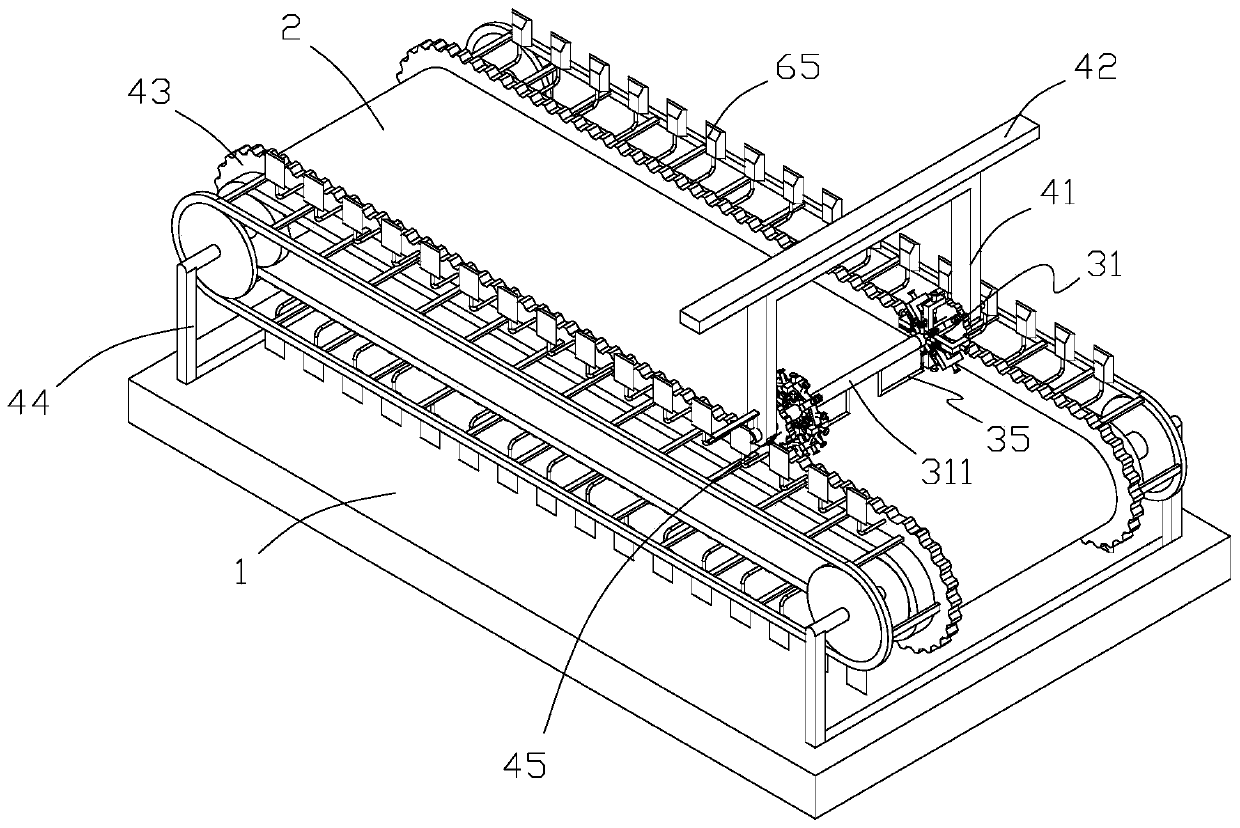

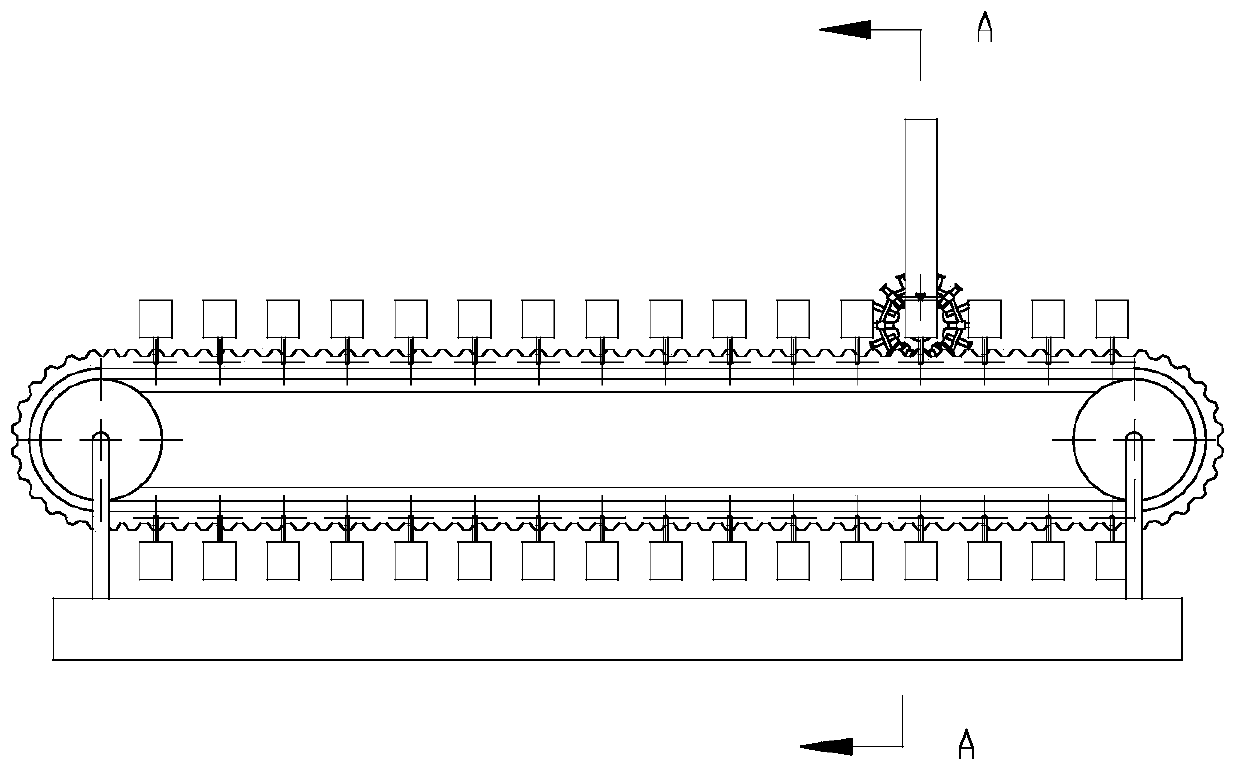

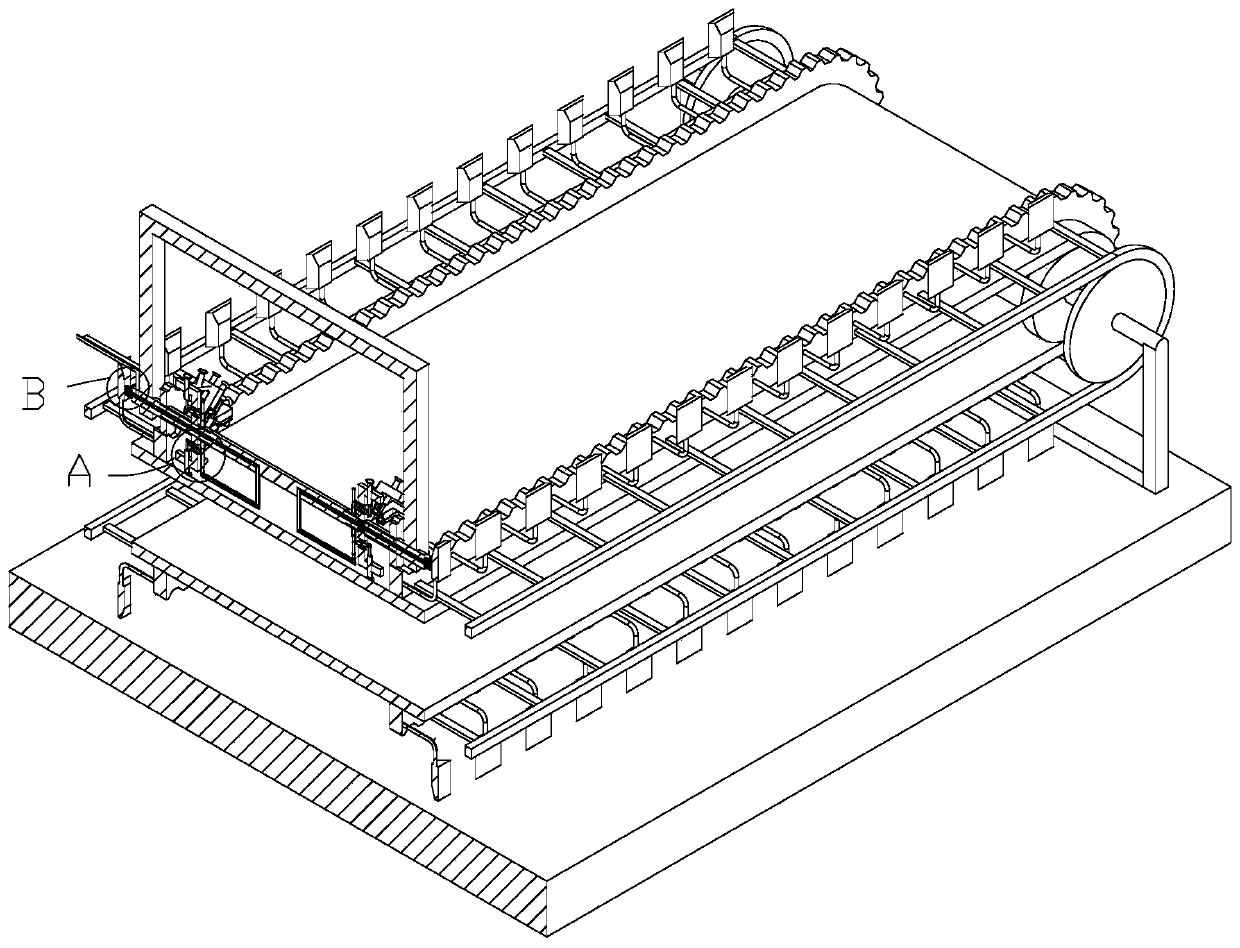

[0029] like Figure 1-11As shown, an automatic dispensing equipment for LED lamp tube processing, including a base 1, a glue application device and a displacement device, wherein the base 1 is provided with a conveyor belt 2; the glue application device is used for dispensing the light strips on the conveyor belt For glue operation, the displacement device is used to drive the dispensing disc to reciprocate along the length direction of the conveyor belt 2 and to drive the dispensing disc 31 to rotate during the reciprocating movement; the gluing devices are set in two groups, respectively On the left and right sides of the conveyor belt, the dispensing discs 31 of the two groups of gluing devices are connected by connecting rods 311, and there is a distance between the two gluing devices; the gluing devices specifically include rotatable dispensing discs 31, located A plurality of dispensing parts 32 on the dispensing tray and a plurality of first fixing parts 33 and second f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com