Method of manufacturing scroll compressor and scroll compressor manufactured therefrom

A scroll compressor, helical technology, applied in rotary piston machinery, machine/engine, rotary piston pump, etc., can solve the problems of different cutting parameters, high cost, different thermal expansion, etc., to achieve uniform coating process , the effect of reducing the number and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

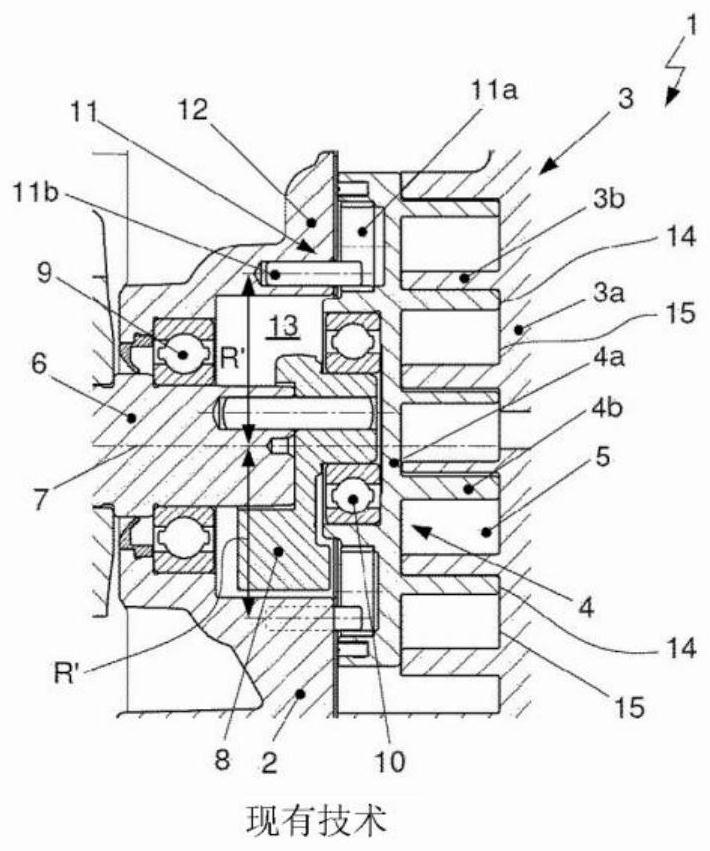

[0066] figure 1 A prior art scroll compressor 1 is shown in a cross-sectional view. The scroll compressor 1 includes a casing 2; an immovable stationary stator 3 having a disk-shaped base plate 3a and a wall 3b formed in a spiral shape extending from one side of the base plate 3a; The movable orbiting scroll 4 is formed in the shape of a wall 4b extending from the front side of the base plate 4a. Also referred to simply as stator 3 and orbiting scroll 4 cooperating as immovable or fixed helical part 3 or movable helical part 4 , respectively. Here, the base plates 3a, 4a are arranged opposite to each other such that the walls 3b of the stator 3 and the walls 4b of the orbiting scroll 4 are staggered. The movable helix 4 is moved along a circular path by an eccentric drive. During the movement of the helical portion 4, the walls 3b, 4b contact at several locations and within the walls 3b, 4b are formed several sequentially closed working volumes 5, wherein the adjacently arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com