Layered anti-aging insulation cover for solid insulation ring network cabinet

A solid insulation, ring network cabinet technology, applied in the direction of layered products, chemical instruments and methods, synthetic resin layered products, etc. Shorten the service life and other problems, to achieve the effect of prolonging the probability of aging, reducing the time, and speeding up the emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

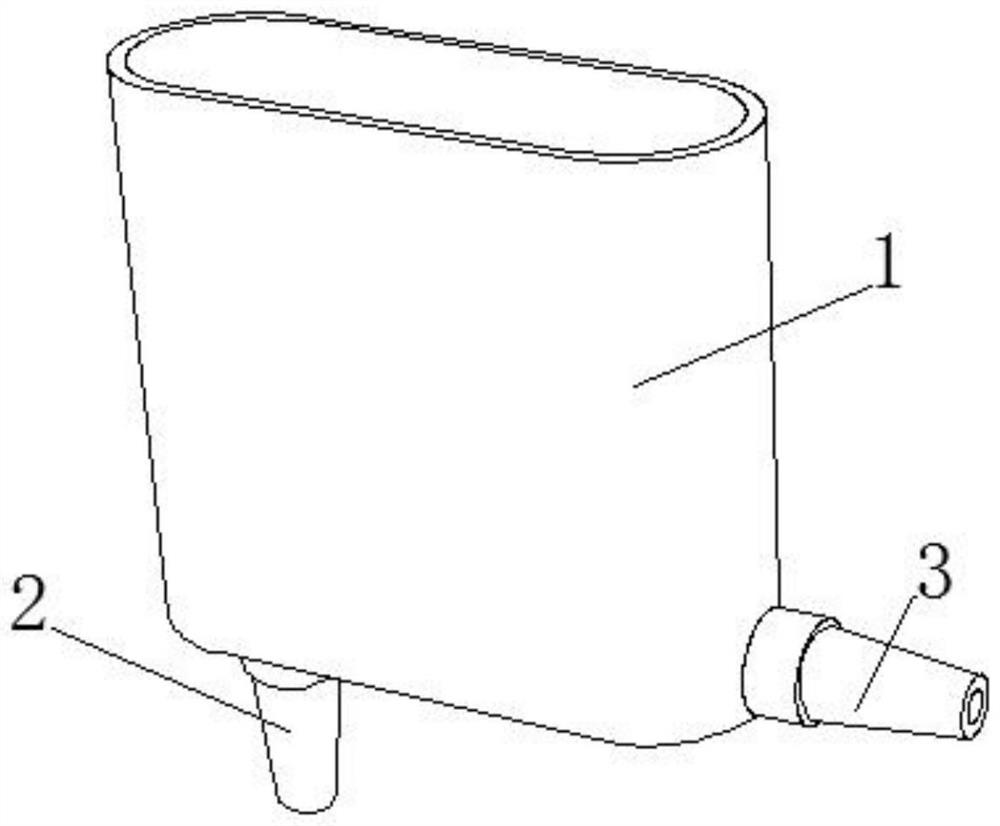

[0043] see figure 1 , a layered anti-aging insulation cover for a solid insulated ring network cabinet, comprising an insulating sleeve body 1, a busbar inlet pipe 2 is fixedly connected to the lower end of the insulating sleeve body 1, and a busbar outlet pipe 3 is fixedly connected to the right end of the insulating sleeve body 1, Both the bus inlet pipe 2 and the bus outlet pipe 3 communicate with the insulating sleeve body 1, and the insulating sleeve body 1 is poured on the switch assembly of the solid insulating ring network cabinet.

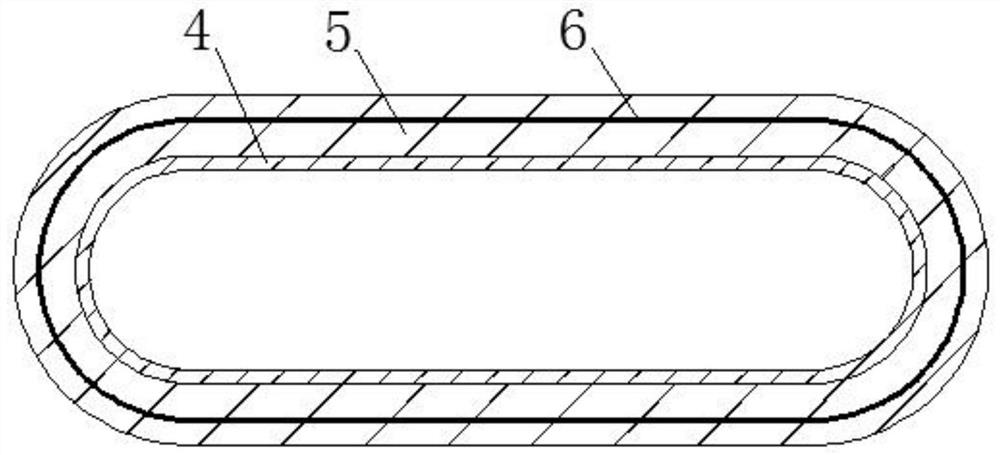

[0044] see figure 2 , the insulating sleeve body 1 is composed of an inner barrier ceramic lining 4, an epoxy resin insulating layer 5 and a nano-sterilizing layer 6, the inner barrier ceramic lining 4 and the epoxy resin insulating layer 5 are poured together, and the inner barrier ceramic lining 4 is located inside the epoxy resin insulation layer 5, and the inner barrier ceramic lining 4 can provide the last protection for the switch ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com