Symmetrical MZ structure double-core optical fiber and manufacturing method thereof

A technology of dual-core optical fiber and production method, which is applied in the directions of multi-core optical fiber, cladding optical fiber, optical waveguide light guide, etc., can solve the problem that the refractive index of the core is not exactly the same, and achieve the effect of high reliability and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

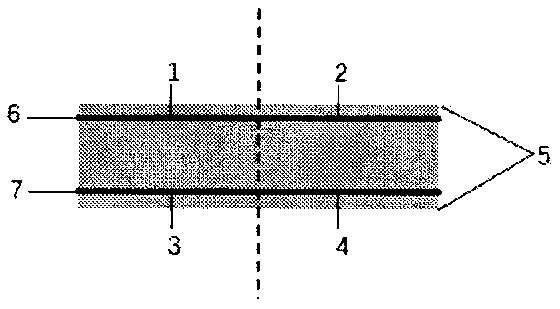

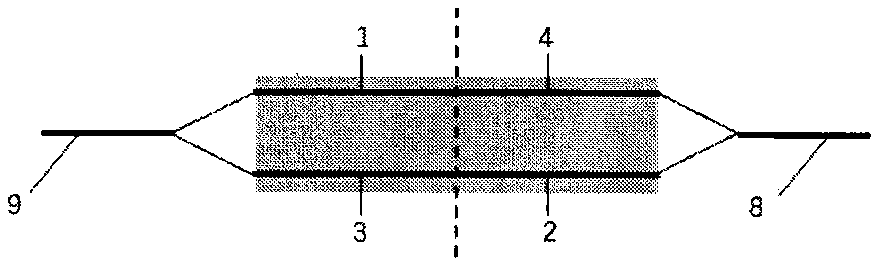

[0032] refer to figure 1 and figure 2 , shows an exemplary symmetrical MZ-structured dual-core fiber. When making a dual-core optical fiber with a symmetrical MZ structure, the dual-core optical fiber 5 comprising the first core 6 and the second core 7 is cut from the middle half to obtain the first half of the first core 6 1 and The second half section 2 and the first half section 3 and the second half section 4 of the second fiber core 7 . Reverse welding at the breakpoint, that is, the first half of the first core 6 1 is connected to the second half 4 of the second core 7, the first half 3 of the second core 7 is connected to the second half 2 of the first core 6, and finally will be reconnected Both ends of the fused double-core optical fiber are connected with single-mode optical fibers 8 and 9 .

[0033] The dual-core optical fiber described in this embodiment preferably has a core radius of 4.1 μm and a distance between cores of 33 μm.

Embodiment 2

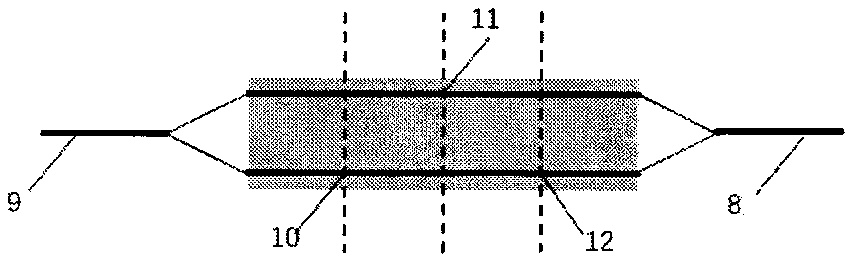

[0035] refer to image 3 , shows an exemplary symmetrical MZ-structured dual-core fiber. When making a symmetrical MZ structure double-core fiber, the double-core fiber 5 comprising the first core 6 and the second core 7 is cut from the middle half 11, reversely fused at the break point, and then A quarter of 10 cuts and reverse fusion, and finally cut and reverse fusion at three quarters of 12, the obtained dual-core optical fiber is symmetrical in structure. Finally, the two ends of the re-spliced double-core optical fiber are connected to single-mode optical fibers 8 and 9 .

[0036] The dual-core optical fiber described in this embodiment preferably has a core radius of 4.1 μm and a distance between cores of 33 μm.

Embodiment 3

[0038] refer to Figure 4, shows an exemplary symmetrical MZ-structured dual-core fiber. When making a symmetrical MZ structure double-core fiber, the double-core fiber 5 comprising the first core 6 and the second core 7 is cut from the middle half 16, reversely fused at the break point, and then respectively Cut and reverse fusion splicing at 1 / 8 13, 1 / 4 14, 3 / 8 15, 5 / 8 17, 3 / 4 18, 7 / 8 19, and the obtained double-core fiber is in the structure above is symmetrical. Finally, the two ends of the re-spliced double-core optical fiber are connected to single-mode optical fibers 8 and 9 .

[0039] The dual-core optical fiber described in this embodiment preferably has a core radius of 4.1 μm and a distance between cores of 33 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com